Powdery polycarboxylic acid water reducing agent, preparation method therefor and application of powdery polycarboxylic acid water reducing agent

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of polycarboxylic acid water reducing agent, can solve the problems of high preparation temperature, reduced powder performance, and reduced water reducing performance of powder, so as to achieve easy industrial production, improved product performance, and guaranteed The effect of the polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

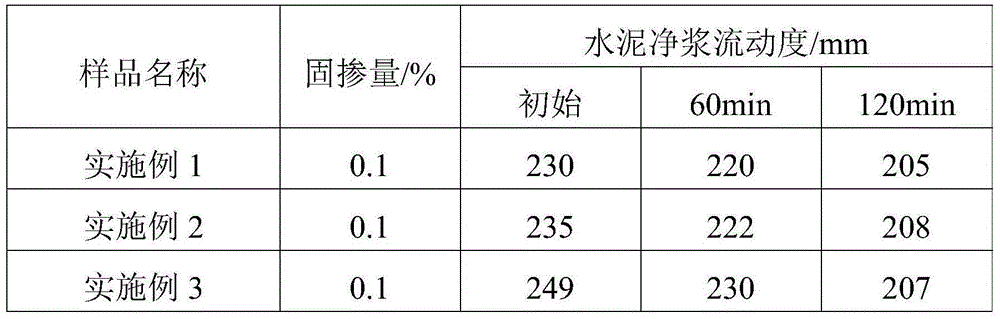

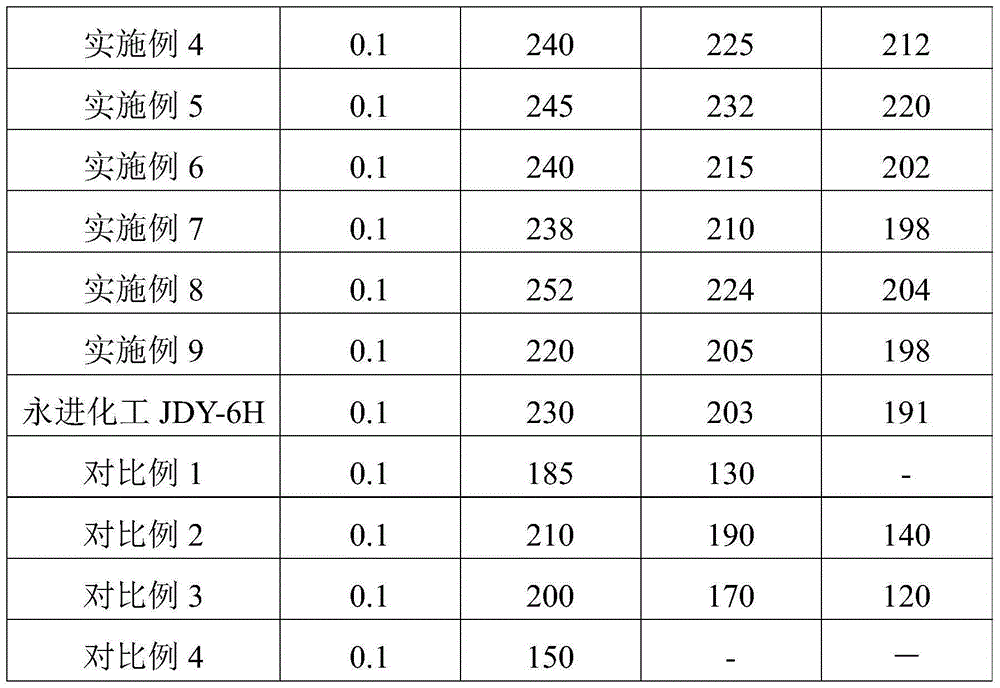

Examples

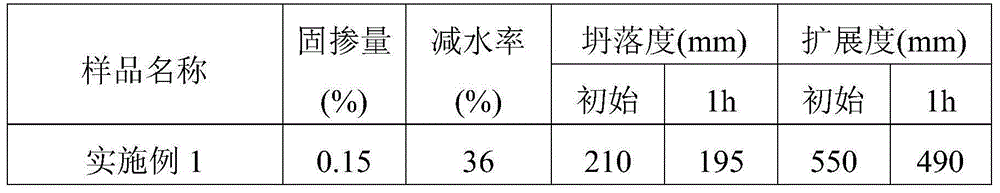

Embodiment 1

[0042] (1), 100 parts of isopentenyl polyoxyethylene ether with a number average molecular weight of 2000, 1 part of hydroxypropyl acrylate, 1 part of sodium allyl sulfonate, 1 part of 2-acrylamide-2-methyl Sodium propanesulfonate and 0.5 parts of methacrylic acid were poured into the reaction kettle, heated and stirred to melt completely; then after the temperature was raised to 55°C, 0.36 parts of azobisisoheptonitrile was added to initiate the reaction;

[0043] (2) Under stirring at 55°C, add dropwise a mixed solution composed of 0.6 parts of mercaptopropionic acid and 9.5 parts of methacrylic acid for 3 hours, of which 70% of the mixed solution is evenly added in the first 1.5 hours. Add the remaining mixed solution uniformly for 1.5h, and add 0.24 parts of azobisisoheptonitrile during the reaction for 1.5h;

[0044] (3) After the dripping is completed, heat the reaction for 2 hours, slowly add 4 parts of sodium hydroxide, pour it out while it is hot, cool, and pulverize into ...

Embodiment 2

[0046] (1), 100 parts of isopentenyl polyoxyethylene polyoxypropylene ether with a number average molecular weight of 5000, 1 part of sodium styrene sulfonate, 1 part of sodium vinyl sulfonate, 1 part of maleic anhydride and 3 parts Pour the acrylic acid into the reaction kettle, heat and stir to melt it completely; then after the temperature is raised to 65°C, 0.36 parts of ammonium persulfate is added to initiate the reaction;

[0047] (2) Under stirring at 65°C, add dropwise a mixed solution consisting of 2 parts of mercaptopropionic acid and 12 parts of acrylic acid for 2 hours, of which 85% of the mixed solution is uniformly added in the first 1 hour, and then uniformly added in the next 1 hour The remaining mixed solution, and adding 0.24 parts of ammonium persulfate during the reaction for 1 hour;

[0048] (3) After the dripping is completed, heat preservation and reaction for 1 hour, slowly add 6 parts of sodium hydroxide, pour out while hot, cool, and pulverize into 100 me...

Embodiment 3

[0050] (1) Pour 100 parts of isopentenyl polyoxyethylene ether with a number average molecular weight of 4000, 2 parts of acrylic acid, 1 part of sodium methacrylate sulfonate, 1 part of itaconic acid and 1 part of hydroxyethyl acrylate In the reaction kettle, heat and stir to make it melt completely; then after heating to 60°C, add 0.36 parts of peroxydicarbonic acid (bis-2-phenoxyethyl) to initiate the reaction;

[0051] (2) Under stirring at 60°C, add dropwise a mixed solution consisting of 2 parts of thioglycolic acid and 18 parts of acrylic acid for 3 hours, of which 70% of the mixed solution is evenly added in the first 1.5 hours, and the latter 1.5 hours are uniform Add the remaining mixed solution, and add 0.24 parts of peroxydicarbonic acid (bis-2-phenoxyethyl ester) during the reaction for 1.5 hours;

[0052] (3) After the dripping is completed, heat the reaction for 1.5 hours, pour it out while it is hot, cool, and pulverize into 400 mesh solid particles to obtain a powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com