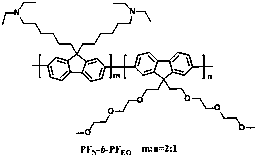

A preparation method of polyfluorene block conjugated polymer cathode buffer layer

A conjugated polymer and cathode buffer layer technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc. to improve the interface barrier, improve the morphology, and improve the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

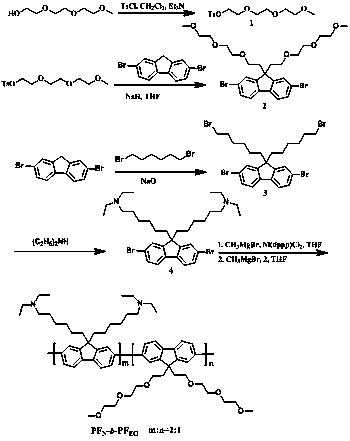

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] The reaction equation of the present invention is attached figure 2 , the specific reaction steps are as follows:

[0012] Synthetic steps of 2-(2-(2-methoxyethoxy)ethoxy)ethyl-4-methylbenzenesulfonate (compound 1):

[0013] Triethylene glycol monomethyl ether (8.2 g, 50.0 mmol) and 4-methylbenzenesulfonyl chloride (10.5 g, 55.1 mmol) were dissolved in 120 mL THF solution and added to a 250 mL round bottom flask. The reaction system was cooled to 0 °C with an ice bath. 10.0g NaOH was dissolved in 50 mL deionized water and added dropwise to the above reaction solution, gradually raised to room temperature and stirred to react overnight, the reaction solution was washed with sodium bicarbonate to remove unreacted sulfonate, and washed with dichloromethane and water Extraction with MgSO 4 Dry, filter and spin dry. Through the column with ethyl acetate / petrole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com