Preparation method of water insoluble fish gelatin protein film

A gelatin protein, water insoluble technology, applied in the direction of flexible covering, transportation and packaging, packaging, etc., can solve the problem of weak water resistance of gelatin protein film, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

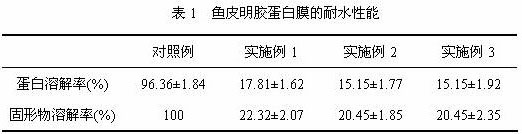

Examples

Embodiment 1

[0023] Add 0.6L of pure water to 200g of tilapia skin gelatin protein, after swelling at room temperature, heat it in a 60°C water bath for 3 hours to dissolve it, add 40g of glycerin and 2g of calcium chloride, mix well, defoam and prepare fish Skin gelatin film liquid; preheat the casting knife to 60°C, use it to evenly coat the prepared fish skin gelatin film liquid on the silicone resin belt, and dry it to form a fish skin with a thickness of about 50 microns gelatin film;

[0024] After dispersing 100g of sodium alginate with 2L of pure water, heat it in a 60°C water bath for 1 hour to dissolve it, add 20g of glycerin, mix evenly, and defoam to prepare a sodium alginate film solution, and use a casting knife to cast the prepared seaweed The sodium alginate film liquid is evenly coated on the surface of the fish skin gelatin protein film, and a sodium alginate-fish skin gelatin protein composite film with a thickness of about 60 microns is formed by drying;

[0025] The d...

Embodiment 2

[0027] Add 0.8L of pure water to 200g of silver carp skin gelatin protein, after swelling at room temperature, heat it in a 70°C water bath for 2 hours to dissolve, add 50g of glycerin and 6g of calcium chloride, mix well, and defoam to prepare fish skin Gelatin protein film liquid; preheat the casting knife to 60°C, use it to evenly coat the prepared fish skin gelatin protein film liquid on the silicone resin belt, and dry it to form fish skin gelatin with a thickness of about 60 microns Protein film;

[0028] After dispersing 100g of sodium alginate with 3L of pure water, heat it in a 70°C water bath for 2 hours to dissolve it, add 25g of glycerin, mix evenly, and defoam to prepare a sodium alginate film solution, and use a casting knife to cast the prepared seaweed The sodium alginate film liquid is evenly coated on the surface of the fish skin gelatin protein film, and a sodium alginate-fish skin gelatin protein composite film with a thickness of about 70 microns is formed...

Embodiment 3

[0031] Add 1L of pure water to 200g of cod skin gelatin protein, after swelling at room temperature, heat it in a water bath at 80°C for 1 hour to dissolve it, add 60g of glycerin and 10g of calcium chloride, mix well, defoam and prepare fish skin gelatin protein Film solution: Preheat the casting knife to 60°C, use it to evenly coat the prepared fish skin gelatin film on the silicone resin belt, and dry it to form a fish skin gelatin film with a thickness of about 70 microns ;

[0032] After dispersing 100g of sodium alginate with 4L of pure water, heat it in a water bath at 80°C for 1 hour to dissolve it, add 30g of glycerin, mix evenly, and defoam to prepare a sodium alginate film liquid, and use a casting knife to cast the prepared seaweed The sodium alginate film liquid is evenly coated on the surface of the fish skin gelatin protein film, and a sodium alginate-fish skin gelatin protein composite film with a thickness of about 80 microns is formed by drying;

[0033] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com