Foamed polypropylene bead containing beta crystal and preparation method thereof

A technology of foaming beads and polypropylene, which is applied in the field of foaming materials, can solve the problems of batch stability, unfavorable polypropylene foaming, and increasing the cost of resin raw materials, and achieve the effect of small crystal size and high crystal density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

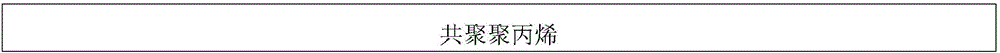

Embodiment 1

[0037] Prepare polypropylene foam beads and molded body materials according to the following steps:

[0038] S1. Composite 5 parts of β nucleating agent, 5 parts of synergist, 1 part of antioxidant, and 89 parts of homopolypropylene resin, and granulate through twin-screw to prepare β nucleating agent masterbatch;

[0039] S2. Add 100 parts of homopolypropylene resin, 1 part of β-nucleating agent masterbatch, 0.5 parts of antistatic agent, and 3 parts of foaming nucleating agent mixture into the twin-screw extruder, and granulate through twin-screw extrusion , to obtain polypropylene particles with β crystals;

[0040] S3. Put 1kg of polypropylene particles and 5L of water into the autoclave, and put high-pressure CO 2 The fluid is injected into the autoclave, and the autoclave is raised from room temperature to 145°C, 150°C, and 155°C, and the pressure is raised to 6.0MPa, so that the blowing agent penetrates into the polypropylene particles;

[0041] S4. Release the pressu...

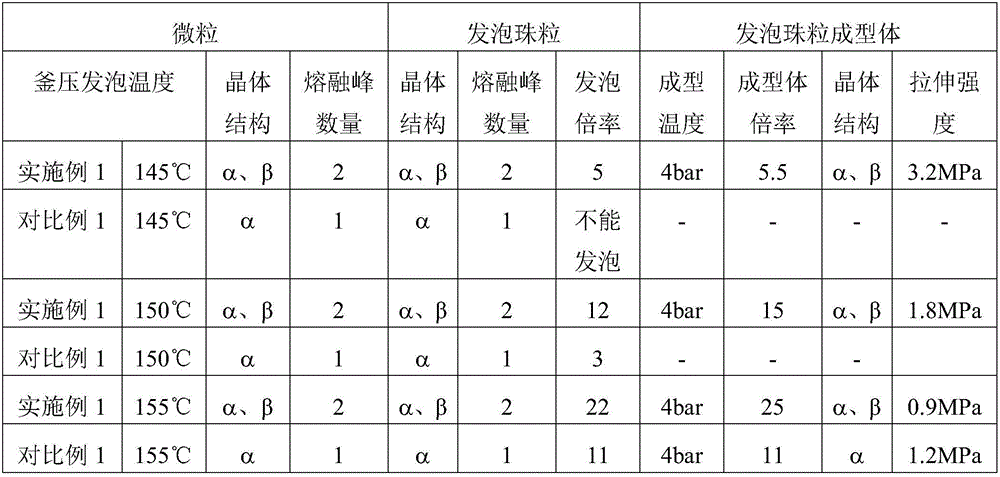

Embodiment 2

[0051] Except that after reaching 150° C., the kettle body was subjected to isothermal treatment for 10 to 15 minutes, other operations were the same as in Example 1.

Embodiment 3

[0059] Except that the polypropylene resin is a random copolymerized polypropylene resin, the foaming temperature is 130° C., 135° C., and the steam molding pressure is 2 bar, other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com