A pvc high weather resistance rainwater pipe

A rainwater pipe and weather-resistant technology, which is applied in the field of polymers, can solve the problems of weather resistance restricting the service life of PVC-U rainwater pipes, poor weather resistance of pipes, and affecting service life, so as to enrich product types, improve physical and chemical properties, and prolong service life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

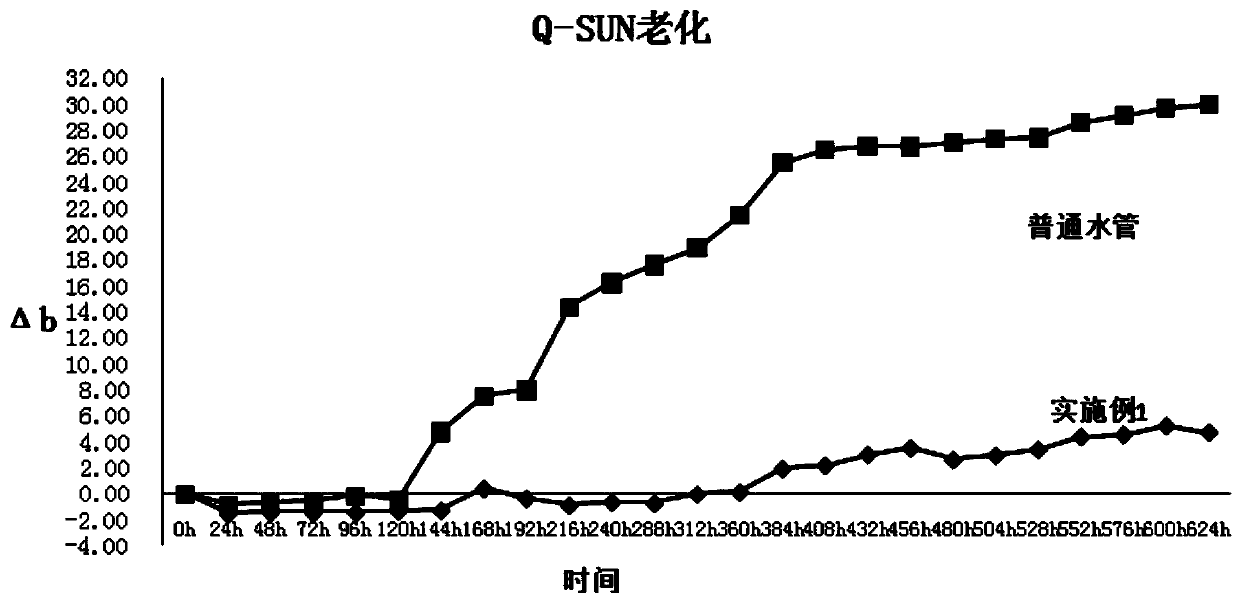

Embodiment 1

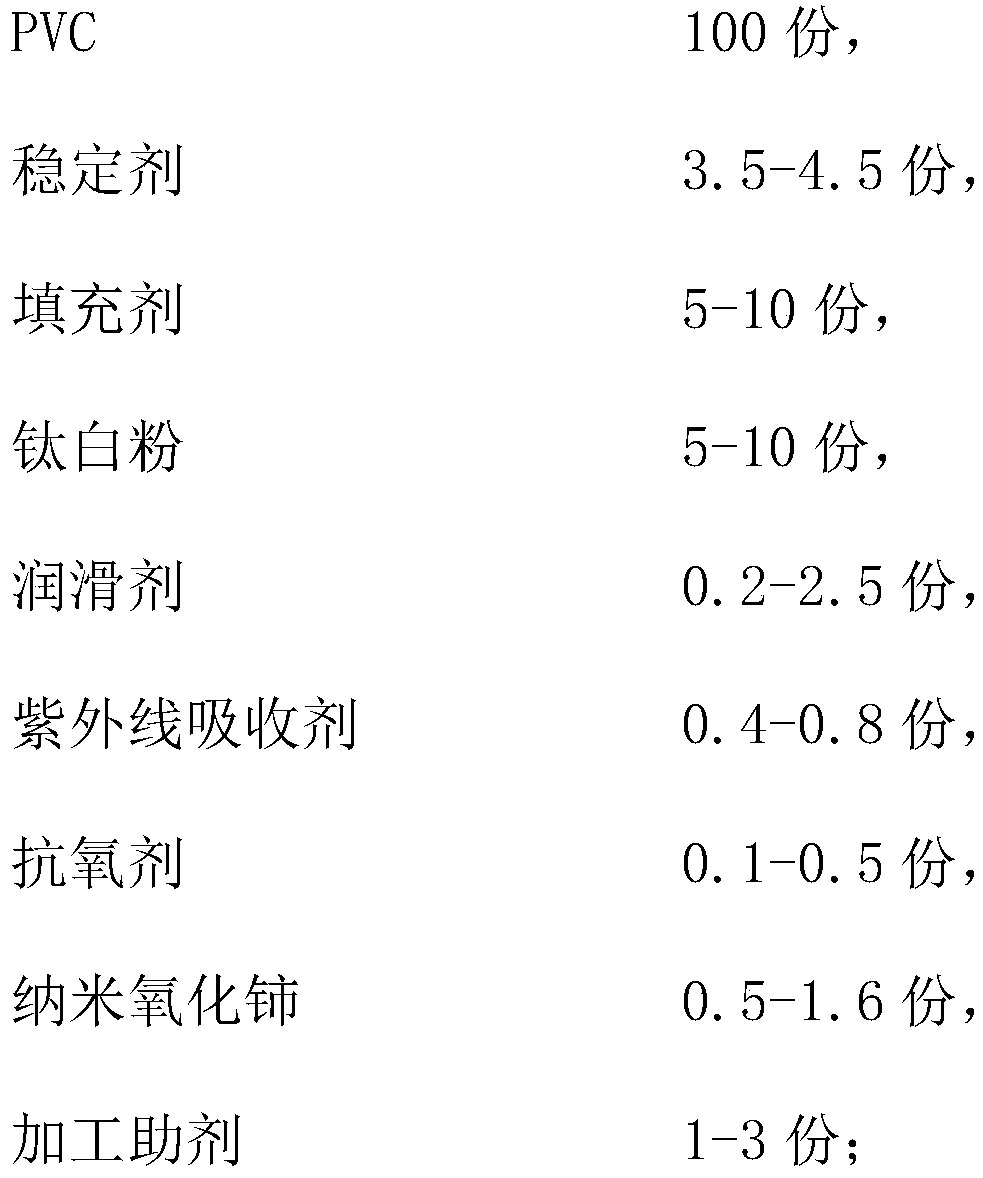

[0057] A PVC high-weather-resistant rainwater pipe, the rainwater pipe includes an outer layer pipe and an inner layer pipe;

[0058] The outer pipe is made of raw materials including the following parts by weight: 100 parts of PVC, 3.5 parts of calcium zinc stabilizer, 5 parts of filler, 2.9 parts of rutile titanium dioxide, 2.1 parts of anatase titanium dioxide, 0.2 parts of PE wax 0.4 part of benzophenone UV531, 0.4 part of polyphenol antioxidant 1010, 0.5 part of nano cerium oxide, 1 part of ACR;

[0059] The inner pipe is made of the following raw materials by weight: 100 parts of PVC, 15 parts of calcium carbonate, 3 parts of calcium zinc stabilizer, 1.5 parts of titanium dioxide, 0.8 parts of ACR, and 0.1 part of PE wax;

[0060] The outer pipe material accounts for 10% of the mass of the rainwater pipe. The particle size of the nano cerium oxide is 6nm.

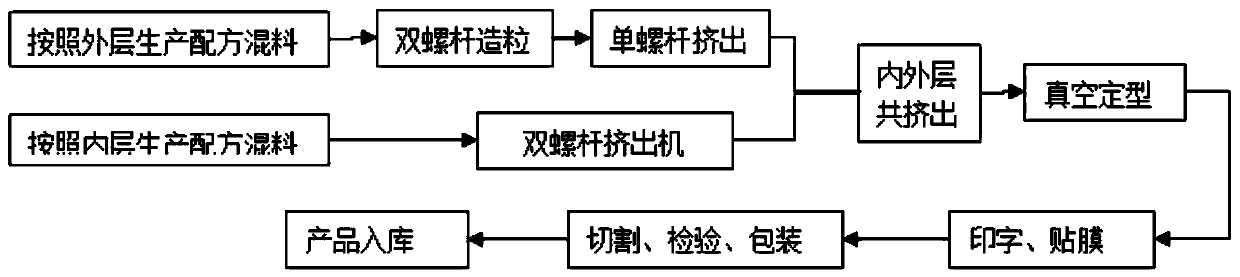

[0061] The preparation method of described PVC high weather resistance rainwater pipe, comprises the steps:

[0...

Embodiment 2

[0066] A PVC high-weather-resistant rainwater pipe, the rainwater pipe includes an outer layer pipe and an inner layer pipe;

[0067] The outer layer pipe is made of raw materials including the following parts by weight: 100 parts of PVC, 4 parts of calcium zinc stabilizer, 8 parts of red mud, 4.6 parts of rutile titanium dioxide, 3.4 parts of anatase titanium dioxide, 0.8 parts of PE wax 0.2 part of stearic acid, 0.5 part of benzophenone UV531, 0.2 part of polyphenol antioxidant 1010, 0.1 part of phosphite antioxidant 168, 0.8 part of nano cerium oxide, 2 parts of ACR;

[0068] The inner pipe is made of the following raw materials by weight: 100 parts of PVC, 15 parts of calcium carbonate, 3 parts of calcium zinc stabilizer, 1.5 parts of titanium dioxide, 0.8 parts of ACR, and 0.1 part of PE wax;

[0069] The outer pipe material accounts for 10% of the mass of the rainwater pipe. The particle size of the nano cerium oxide is 6nm.

[0070] The preparation method of described...

Embodiment 3

[0075] A PVC high-weather-resistant rainwater pipe, the rainwater pipe includes an outer layer pipe and an inner layer pipe;

[0076] The outer pipe is made of raw materials including the following parts by weight: 100 parts of PVC, 4.5 parts of calcium zinc stabilizer, 8 parts of white cherry blossom nano-calcium carbonate, 5.7 parts of rutile titanium dioxide, 4.3 parts of anatase titanium dioxide, 0.5 parts of OPE, 0.7 parts of stearic acid, 0.8 parts of benzotriazole UV-326, 0.2 parts of polyphenol antioxidant 1010, 0.3 parts of thioester antioxidant PS806, 1.4 parts of nano cerium oxide, 2 parts of ACR;

[0077] The inner pipe is made of the following raw materials by weight: 100 parts of PVC, 15 parts of calcium carbonate, 3 parts of calcium zinc stabilizer, 1.5 parts of titanium dioxide, 0.8 parts of ACR, and 0.1 part of PE wax;

[0078] The outer pipe material accounts for 10% of the mass of the rainwater pipe. The particle size of the nano cerium oxide is 6nm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com