Battery positive electrode based on nitrogen-doped carbonized bacterial cellulose, lithium-sulfur battery and preparation methods therefor

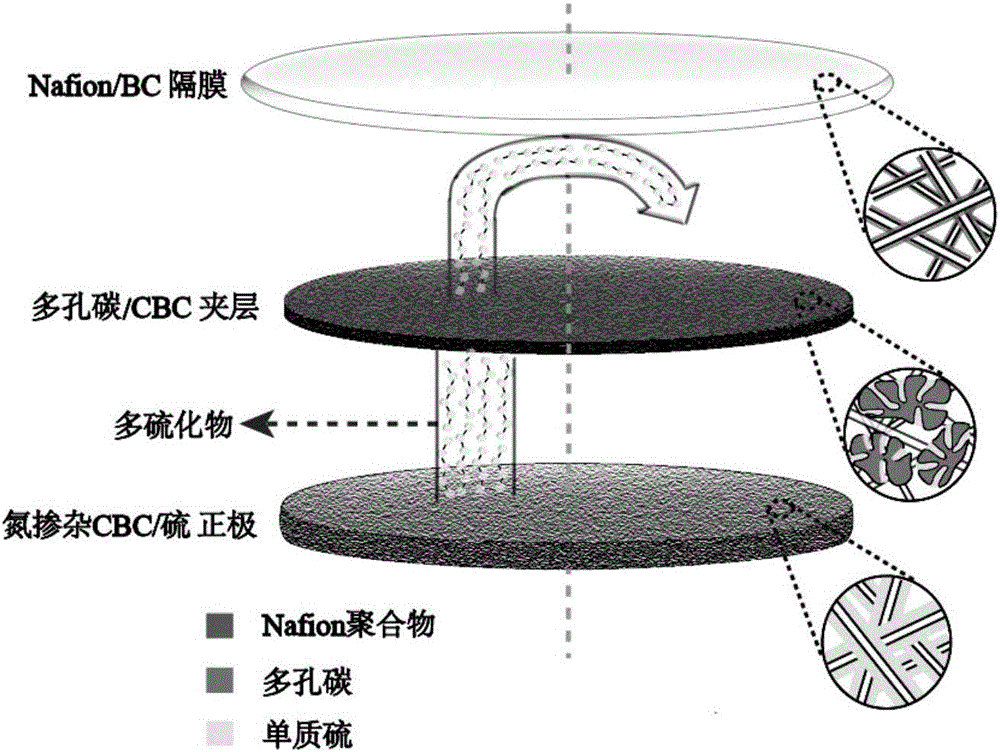

A technology of bacterial cellulose and bacterial cellulose membrane, which is applied in the battery positive electrode based on N-doped carbonized bacterial cellulose, lithium-sulfur battery and its preparation field, to achieve the effect of increasing load capacity, high specific capacity, and stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing battery anode based on N-doped carbonized bacterial cellulose, the specific steps are as follows:

[0028] Step 1. Remove the BC membrane with a thickness of 3.0mm from the culture medium, rinse the excess fermentation liquid on the membrane surface with deionized water, and then freeze-dry to obtain a BC aerogel containing N source.

[0029] Step 2, flatten the BC aerogel containing N source (0.2Mpa positive pressure), and then keep it at 800°C for 2 hours under the protection of an inert atmosphere to obtain NCBC aerogel.

[0030] Step 3. Infiltrate NCBC aerogel into S / CS 2 In the solution, let stand at room temperature for 2h, take it out and put it in a closed container, keep it at 130℃ for 6h, make the elemental S in a molten state, and evenly diffuse into the inside of the NCBC mesh, after cooling, the S / NCBC positive electrode is obtained The prepared S / NCBC cathode material contains 75wt% of S.

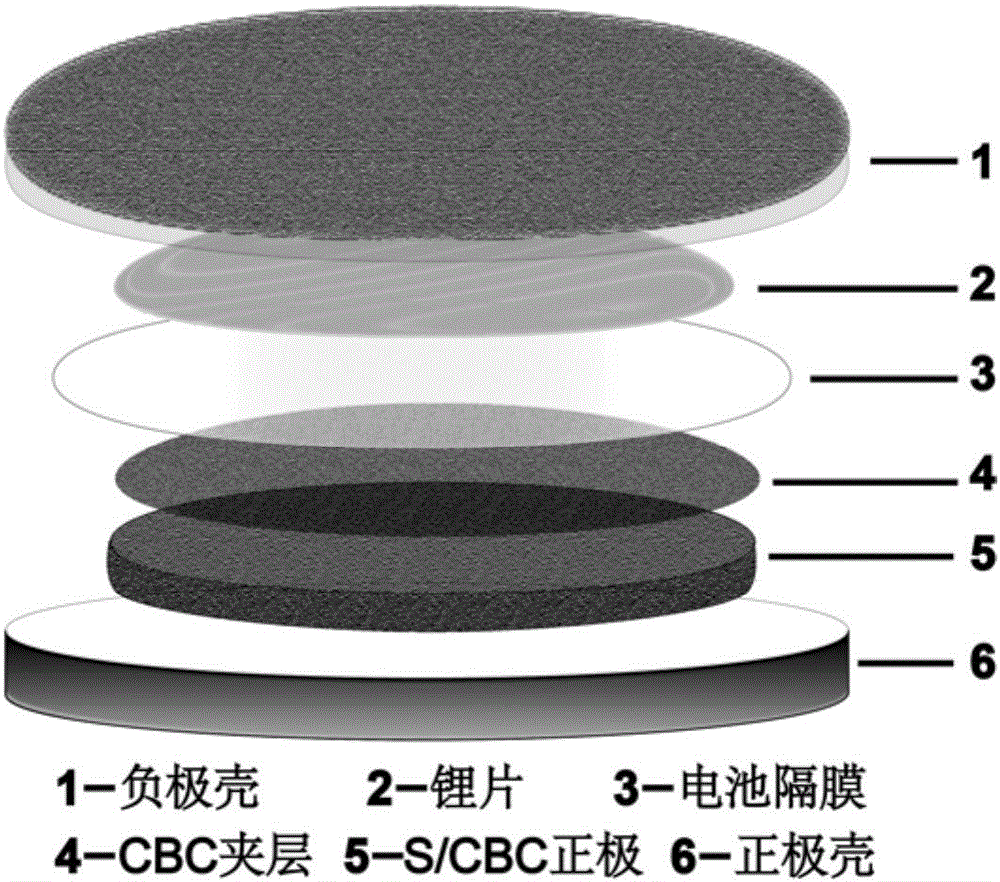

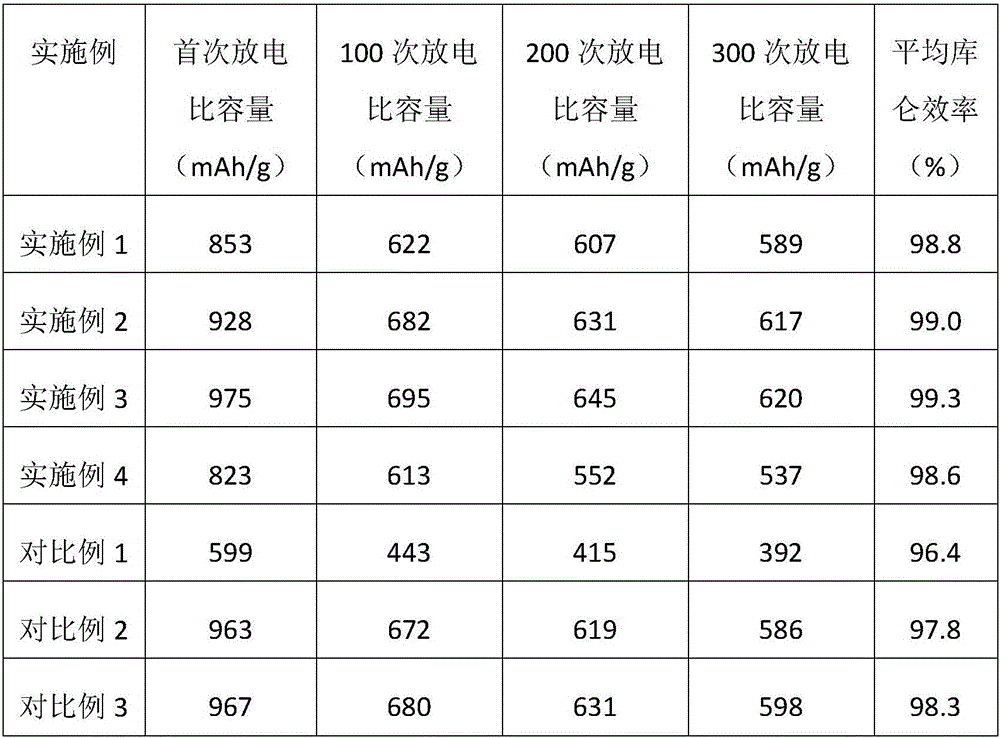

[0031] A Li-S battery assembled using the above N-d...

Embodiment 2

[0037] A method for preparing battery anode based on N-doped carbonized bacterial cellulose, the specific steps are as follows:

[0038] Step 1. Remove the BC membrane with a thickness of 2.0mm from the culture medium, rinse the excess fermentation liquid on the membrane surface with deionized water, and then freeze-dry to obtain a BC aerogel containing N source.

[0039] Step 2, flatten the BC aerogel containing N source (0.2Mpa positive pressure), and then keep it at 900°C for 1 hour under the protection of an inert atmosphere to obtain NCBC aerogel.

[0040] Step 3. Infiltrate NCBC aerogel into S / CS 2 In the solution, let it stand at room temperature for 4h, take it out and put it in a closed container, keep it at 200℃ for 10h, make the elemental S in a molten state, and evenly diffuse into the inside of the NCBC mesh, after cooling, the S / NCBC positive electrode is obtained The prepared S / NCBC cathode material contains 80wt% of S.

[0041] A Li-S battery assembled using the above ...

Embodiment 3

[0047] A method for preparing battery anode based on N-doped carbonized bacterial cellulose, the specific steps are as follows:

[0048] Step 1. Remove the BC membrane with a thickness of 2.0mm from the culture medium, rinse the excess fermentation liquid on the membrane surface with deionized water, and then freeze-dry to obtain a BC aerogel containing N source.

[0049] Step 2, flatten the BC aerogel containing N source (0.2Mpa positive pressure), and then keep it at 1000°C for 1 hour under the protection of an inert atmosphere to obtain NCBC aerogel.

[0050] Step 3. Infiltrate NCBC aerogel into S / CS 2 In the solution, let it stand at room temperature for 6h, take it out and put it in a closed container, keep it at 160℃ for 12h, make the elemental S in a molten state, and evenly diffuse into the inside of the NCBC mesh, after cooling, the S / NCBC positive electrode is obtained The prepared S / NCBC positive electrode material contains 82wt% of S.

[0051] A Li-S battery assembled usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com