Methanol-to-aromatic hydrocarbon lightweight product utilization method

A methanol and product technology, which is applied in the field of utilization of light products of methanol to aromatics, can solve the problem of high energy consumption in gas separation, and achieve the effects of reducing energy consumption, reducing energy consumption, and reducing feed load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

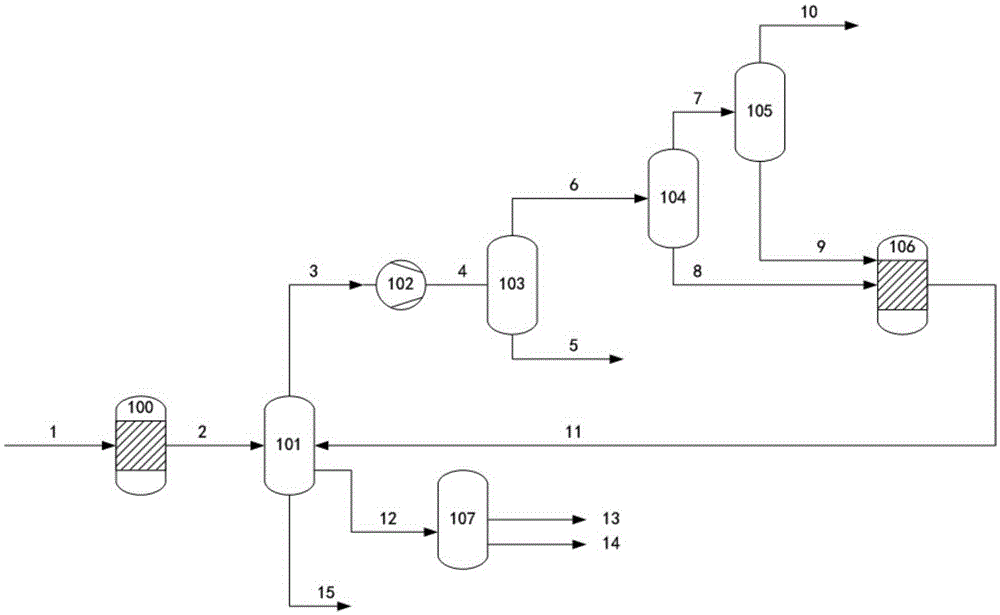

[0024] according to figure 1 The process flow shown. Methanol with a scale of 1.8 million tons / year is reacted in a methanol reactor to produce 1.2wt% hydrogen, 1.3wt% methane, 0.2wt% carbon dioxide, 55.4wt% water, 16.5wt% and 23.6wt% of C2 to C5 hydrocarbons Methanol aromatization products of other hydrocarbons, after heat exchange cooling, three-phase separation to obtain water phase, oil phase containing heavy hydrocarbons such as benzene, toluene, xylene and hydrogen and light hydrocarbon products such as methane, ethylene , ethane, propylene, propane gas phase, wherein the gas phase contains 53% volume fraction of hydrogen. After the gas phase is boosted to 2.8MPa by the compressor, the acid gas is removed through the alkali washing tower, so that the mass content of carbon dioxide in it is less than 5wppm, and the water is removed through the dryer, so that the mass content of water in it is less than 3wppm, and then sent to into the membrane separation unit. A hollow...

Embodiment 2

[0029] according to figure 1 The process flow shown. Methanol with a scale of 1.8 million tons / year is reacted in a methanol reactor to produce 0.7wt% hydrogen, 1.5wt% methane, 0.2wt% carbon dioxide, 56.3wt% water, and 16.8wt% and 24.5wt% of C2 to C5 hydrocarbons Methanol aromatization products of other hydrocarbons, after heat exchange cooling, three-phase separation to obtain water phase, oil phase containing heavy hydrocarbons such as benzene, toluene, xylene and hydrogen and light hydrocarbon products such as methane, ethylene , ethane, propylene, propane gas phase, wherein the gas phase contains 40.4% volume fraction of hydrogen. After the gas phase is boosted to 2.1MPa by the compressor, the acid gas is removed through the alkali washing tower, so that the mass content of carbon dioxide in it is less than 10wppm, and the water is removed through the dryer, so that the mass content of water in it is less than 8wppm, and then sent to into the membrane separation unit. A...

Embodiment 3

[0032] according to figure 1 The process flow shown. Methanol with a scale of 1.8 million tons / year is reacted in a methanol reactor to produce 2.5wt% hydrogen, 1.2wt% methane, 0.2wt% carbon dioxide, 55.5wt% water, and 16.6wt% and 24.0wt% of C2 to C5 hydrocarbons Methanol aromatization products of other hydrocarbons, after heat exchange cooling, three-phase separation to obtain water phase, oil phase containing heavy hydrocarbons such as benzene, toluene, xylene and hydrogen and light hydrocarbon products such as methane, ethylene , ethane, propylene, propane gas phase, wherein the gas phase contains 69.5% volume fraction of hydrogen. After the gas phase is boosted to 2.5MPa by the compressor, the acid gas is removed through the alkali washing tower, so that the mass content of carbon dioxide in it is less than 6wppm, and the water is removed through the dryer, so that the mass content of water in it is less than 1wppm, and then sent to into the membrane separation unit. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com