A kind of separation method of low-carbon olefin gas

A low-carbon olefin and separation method technology, applied in the field of low-carbon olefin refining, can solve the problems of complex cryogenic separation process and large investment, achieve high separation efficiency, reduce total investment, and increase relative volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

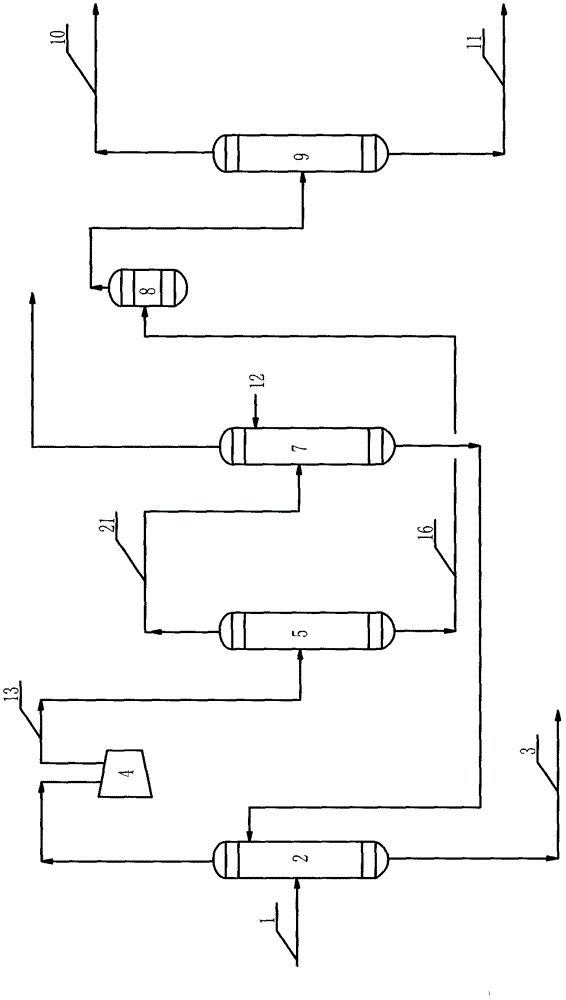

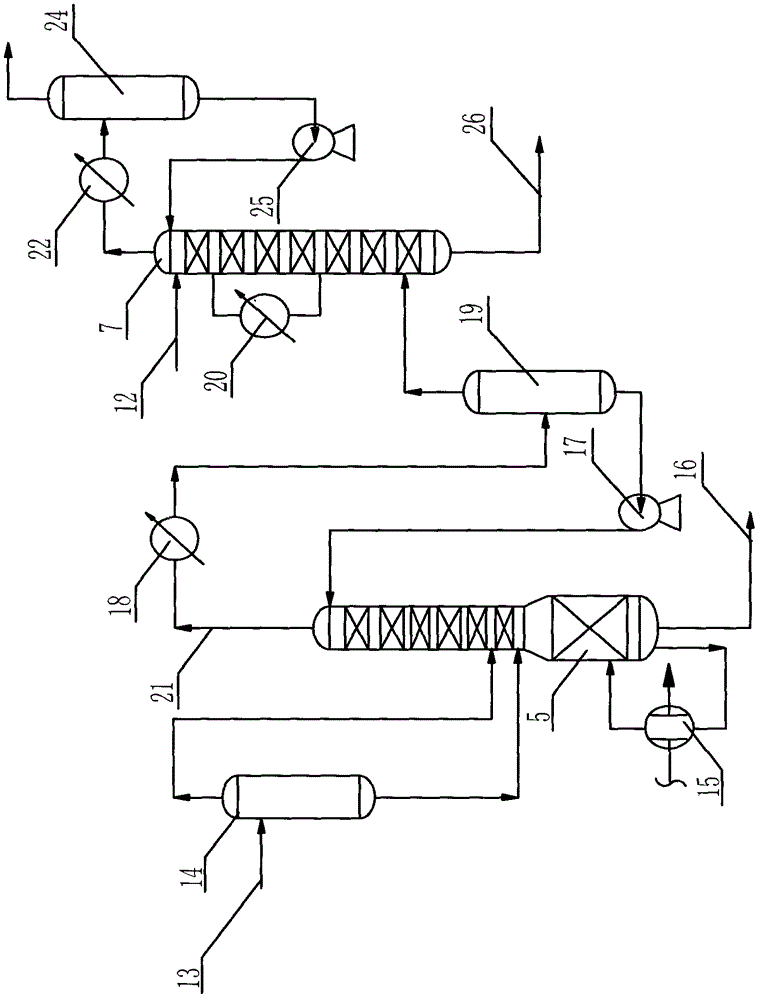

[0036] Such as figure 1 As shown, the MTO reaction gas 1 enters the deethanizer 2 after three-stage compression, water washing, alkali washing and drying of the compressor, and the C 2 The following components and C 3 The above components are separated. The bottom stream 3 of the deethanizer is sent to the depropanization system and the propylene rectification system to separate the polymer grade propylene product. The overhead stream of the deethanizer 2 is compressed by the fourth stage 4 of the compressor, and the compressed gas 13 of the fourth stage enters the demethanizer 5, and the hydrogen, methane and carbon components are separated in the demethanizer 5 .

[0037] The demethanizer bottom stream 16 from the demethanizer 5 is sent to the acetylene converter 8 to selectively remove acetylene, propyne and propadiene to ensure the requirements of polymer grade ethylene products. The stream from the acetylene converter 8 enters the ethylene rectification column 9 to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com