Electric vehicle cooling liquid and preparing method thereof

A coolant and electric vehicle technology, applied in the chemical industry, can solve problems such as environmental protection risks and degradation risks, and achieve the effects of low phosphorus content and good heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

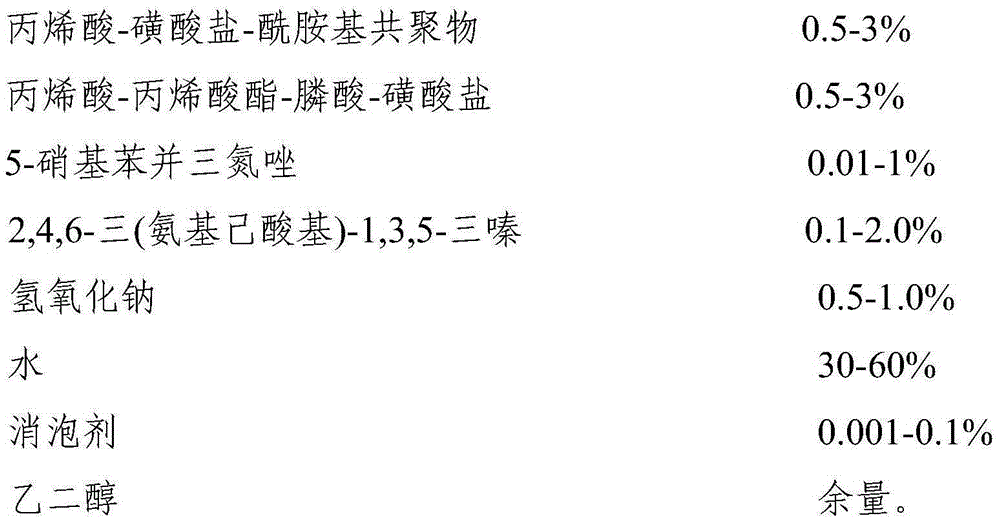

[0027] The components of the electric vehicle coolant of the present embodiment are as follows:

[0028]

[0029] Among them, the acrylic acid-sulfonate-amide-based copolymer is the copolymer TH-615; the acrylic acid-acrylate-phosphonic acid-sulfonate is selected from the tetrapolymer TH-241.

[0030] The preparation method is as follows:

[0031] 1) Dissolve 2,4,6-tris(aminocaproyl)-1,3,5-triazine and sodium hydroxide in part of the water according to the ratio, and set aside;

[0032] 2) Mix acrylic acid-sulfonate-amide-based copolymer, acrylic acid-acrylate-phosphonic acid-sulfonate and ethylene glycol according to the proportion and stir for 45 minutes, then set aside;

[0033] 3) Finally, add the solution of step 1 and step 2 to 5-nitrobenzotriazole, the remaining part of deionized water and defoamer, and stir at room temperature for 45 minutes.

Embodiment 2

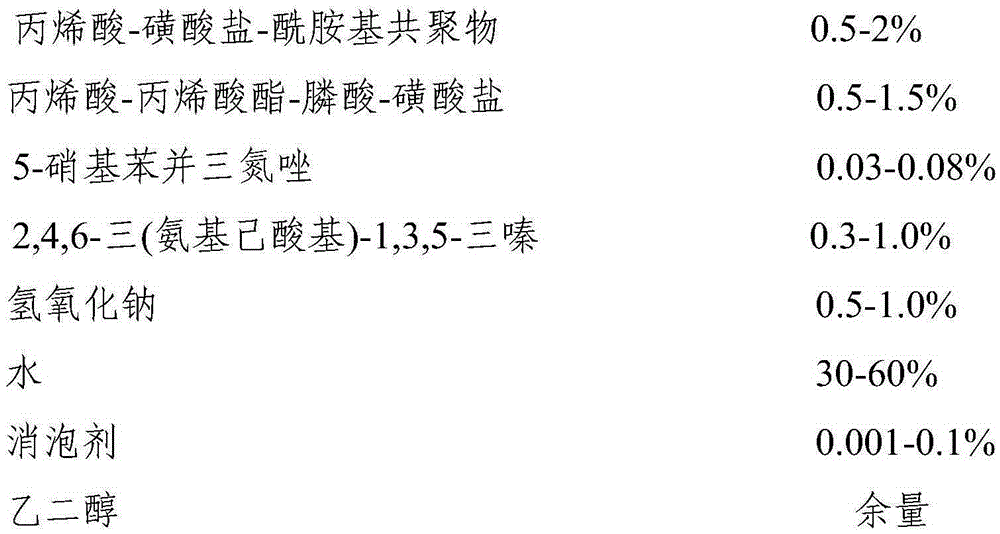

[0035] The components of the electric vehicle coolant of the present embodiment are as follows:

[0036]

[0037]

[0038] Among them, the acrylic acid-sulfonate-amide-based copolymer is the copolymer TH-615; the acrylic acid-acrylate-phosphonic acid-sulfonate is selected from the tetrapolymer DT104.

[0039] The preparation method is as follows:

[0040] 1) Dissolve 2,4,6-tris(aminocaproyl)-1,3,5-triazine and sodium hydroxide in part of the water according to the ratio, and set aside;

[0041] 2) Mix acrylic acid-sulfonate-amide-based copolymer, acrylic acid-acrylate-phosphonic acid-sulfonate and ethylene glycol according to the proportion and stir for 30 minutes, then set aside;

[0042] 3) Finally, add the solution of step 1 and step 2 to 5-nitrobenzotriazole, the remaining part of deionized water and defoamer, and stir at room temperature for 30 minutes.

Embodiment 3

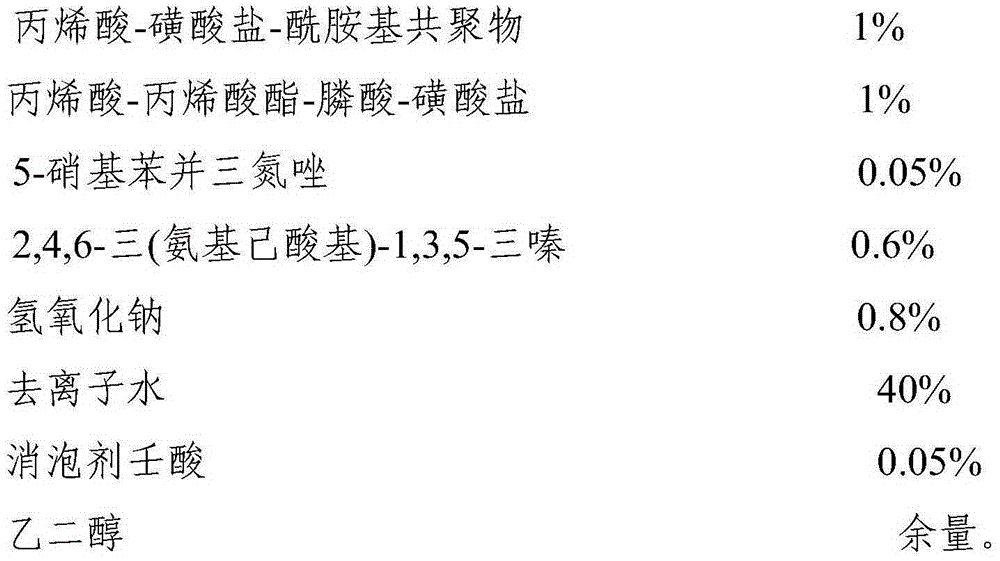

[0044] The components of the electric vehicle coolant of the present embodiment are as follows:

[0045]

[0046] Among them, the acrylic acid-sulfonate-amide-based copolymer is the copolymer TH-615; the acrylic acid-acrylate-phosphonic acid-sulfonate is selected from the tetrapolymer TH-241.

[0047] The preparation method is as follows:

[0048] 1) Dissolve 2,4,6-tris(aminocaproyl)-1,3,5-triazine and sodium hydroxide in part of the water according to the ratio, and set aside;

[0049] 2) Mix acrylic acid-sulfonate-amide-based copolymer, acrylic acid-acrylate-phosphonic acid-sulfonate and ethylene glycol according to the proportion and stir for 60 minutes, then set aside;

[0050] 3) Finally, add the solution of step 1 and step 2 to 5-nitrobenzotriazole, the remaining part of deionized water and defoamer, and stir at room temperature for 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com