A kind of elastic conductive nanofiber yarn and preparation method thereof

A nanofiber, elastic and conductive technology, applied in the field of flexible electrode preparation, can solve the problems of high cost, complicated carbon nanotube fiber preparation process, non-continuous production, etc., to overcome poor flexibility, good carbon tube adsorption effect, and improve mechanical properties and the effect on electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

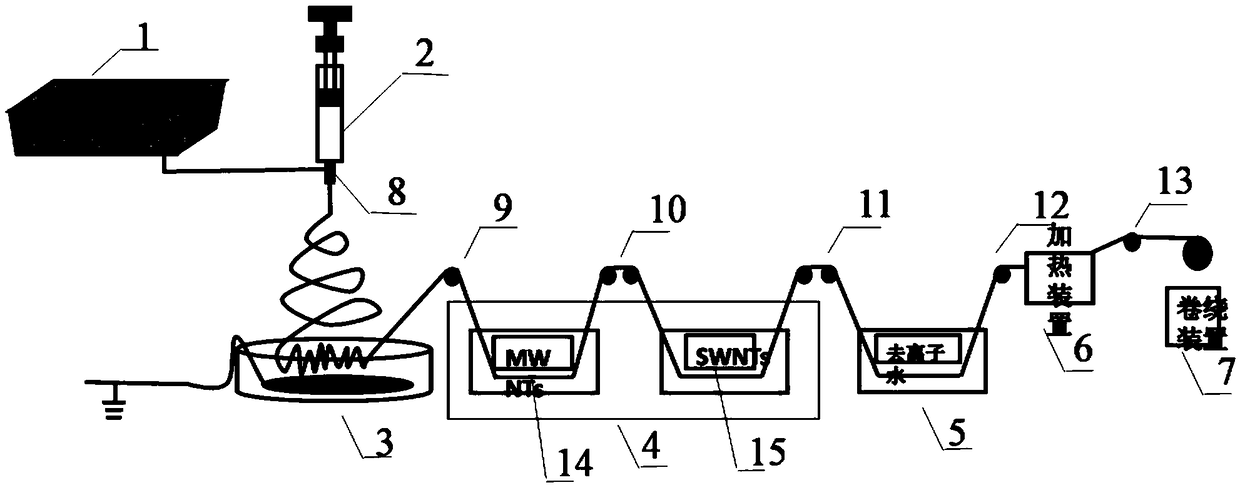

[0042] An elastic conductive nanofiber yarn device such as figure 1 As shown, it includes a high-voltage power supply 1, a spraying device 2, a water bath receiving device 3, an ultrasonic device 4, a cleaning device 5, a heating device 6, a winding collection device 7 and five godet rollers; wherein, the high-voltage power supply 1 is connected to the spraying device 2 The spinneret 8 and the spraying device 2 are adjustable in height. The horizontal distance from the spinneret 8 of the spraying device 2 to the inner wall of the water bath receiving device 3 is controlled at 2 to 10 cm, and the vertical distance is controlled at 5 to 30 cm. The water bath receiving device 3 is located at the Below the device 2; the ultrasonic device 4 includes two ultrasonic machines, in each ultrasonic machine, the first glass bend 14 and the second glass bend 15 are respectively fixed, the first glass bend 14 holds the MWNTs aqueous dispersion, The SWNTs aqueous dispersion is filled in the ...

Embodiment 2

[0044] Raw material source:

[0045] Thermoplastic Polyurethane (TPU): Density 1.12g / cm 3 , Germany BASF Polyurethane Co., Ltd.;

[0046] Surfactant sodium dodecyl sulfate (SDS) is chemically pure, whiteness 60%, Sinopharm Chemical Reagent Co., Ltd.;

[0047] Single-walled carbon nanotubes (SWNTs) are high-purity single-walled carbon nanotubes, and the product label is TNSR; carboxylated multi-walled carbon nanotubes (MWNTs) are high-purity multi-walled carbon nanotubes, and the product label is TNMC5; Chemical Limited;

[0048] N,N-Dimethylformamide (DMF) is analytically pure, content ≥ 99.5%, Tianjin Fuyu Fine Chemical Co., Ltd.;

[0049] The tetrahydrofuran (THF) is analytically pure, with a content ≥ 90%, from Tianjin Fuyu Fine Chemical Co., Ltd.;

[0050] The high voltage power supply is Dongwen High Voltage Power Supply (Tianjin) Co., Ltd.

[0051] The structural parameters of the elastic conductive nanofiber yarn device are: the horizontal distance from the tip of ...

Embodiment 3

[0063] Raw material source:

[0064] Thermoplastic Polyurethane (TPU): Density 1.12g / cm 3 , Germany BASF Polyurethane Co., Ltd.;

[0065] Surfactant sodium dodecyl sulfate (SDS) is chemically pure, whiteness 60%, Sinopharm Chemical Reagent Co., Ltd.;

[0066] Single-walled carbon nanotubes (SWNTs) are high-purity single-walled carbon nanotubes, and the product label is TNSR; carboxylated multi-walled carbon nanotubes (MWNTs) are high-purity multi-walled carbon nanotubes, and the product label is TNMC5; Chemical Limited;

[0067] N,N-Dimethylformamide (DMF) is analytically pure, content ≥ 99.5%, Tianjin Fuyu Fine Chemical Co., Ltd.;

[0068] The tetrahydrofuran (THF) is analytically pure, with a content ≥ 90%, from Tianjin Fuyu Fine Chemical Co., Ltd.;

[0069]The high voltage power supply is Dongwen High Voltage Power Supply (Tianjin) Co., Ltd.

[0070] The structural parameters of the elastic conductive nanofiber yarn device are: the horizontal distance from the tip of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com