Automobile 4S store spraying waste gas treatment device and technology thereof

An exhaust gas treatment device and 4S shop technology, applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of secondary pollution, expensive, complex catalyst preparation, etc., to improve efficiency and promote active substances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

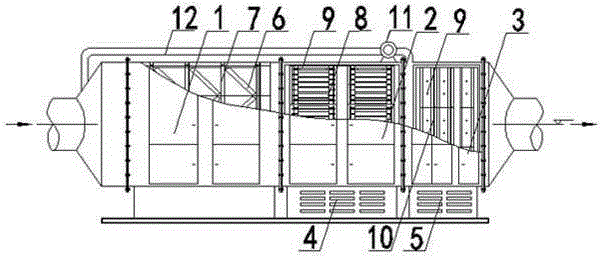

[0044] In this embodiment, the length of the dry paint mist treatment unit 1 of the spraying waste gas treatment device of the automobile 4S shop is 1000mm, the length of the UV enhanced plasma treatment unit 2 is 1000mm, the length of the adsorption degradation unit 3 is 1000mm, and the length of the return pipe 12 is 2200mm. The total length is 4000mm, the width is 1500mm, and the processing unit height is 2000mm. The dry paint mist treatment unit 1 is equipped with 3 layers of dry paint mist filter materials 5, one layer in the front section is Hengshunda brand glass fiber filter cotton, the filtration accuracy is ≥ 5 μm, and the rear section is a total of two layers of Handu brand glass fiber Filter cotton, the filtration accuracy is ≥1μm. The UV enhanced plasma treatment unit 2 adopts double dielectric barrier discharge as the plasma generation method, and the discharge voltage is 35kV. The size of a single module is 500mm×700mm×1000mm, and there are 20 double dielectric...

Embodiment 2

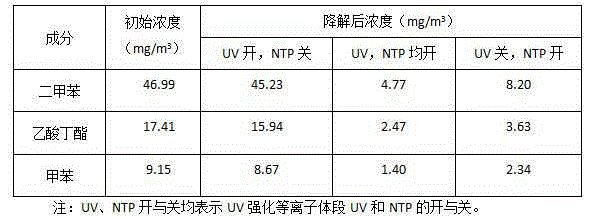

[0049] In this embodiment, the whole device is exactly the same as in Embodiment 1, and the design air volume is 22000 m 3 / h, the design intake interface size is 2000mm×1500mm, and the design exhaust gas flow rate is 2.03m / s. The difference is that in this embodiment, the return pipe is firmly blocked and there is no return process. The main components of the exhaust gas are xylene, butyl acetate and toluene, and the temperature is normal temperature. The contents of pollutants and ozone before and after waste gas treatment are shown in Table 2.

[0050] Table 2 Concentrations before and after treatment of spray paint exhaust gas under the condition of no reflux

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com