Monodisperse porous zirconium dioxide-cerium dioxide composite microsphere and preparation method thereof

A ceria and zirconia technology, which is applied in the field of monodisperse porous zirconia-ceria composite microspheres and the preparation thereof, can solve the problem that it is only suitable for chromatographic separation of small molecular compounds, and achieves high mechanical strength and size. And the effect of controllable pore size and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

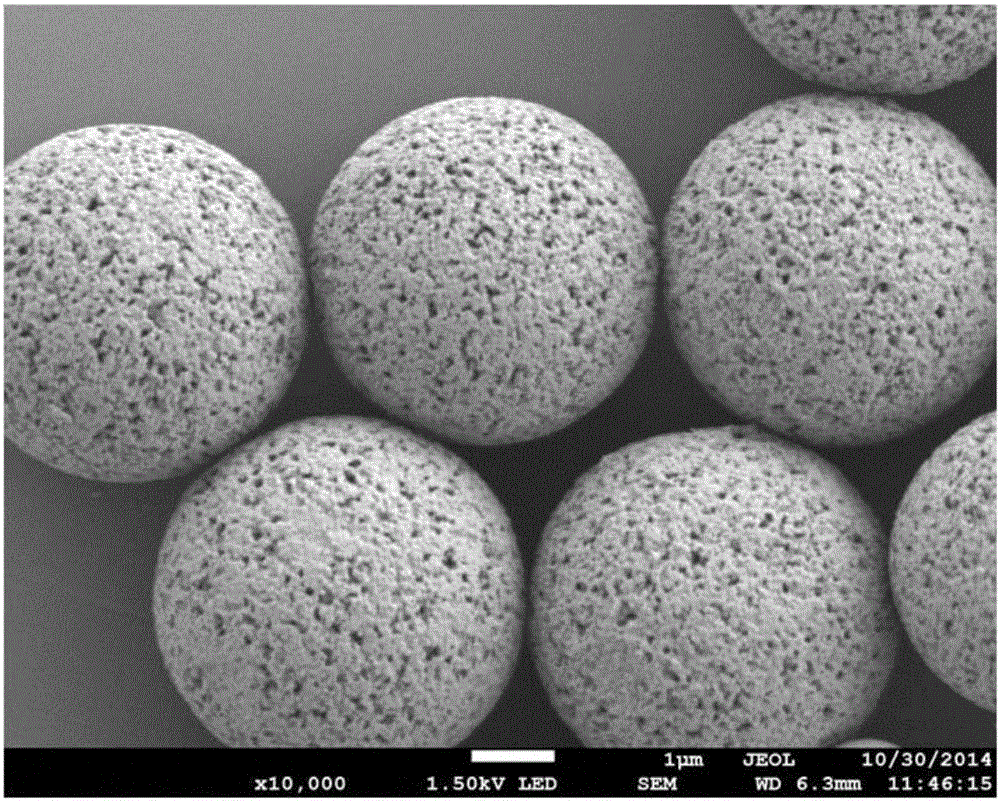

[0035] In this example, the commercially available porous PGMA / EGDMA microspheres with a particle size of 5 μm were used as a template to prepare the monodisperse porous zirconia-ceria composite microspheres of this example. The specific preparation method is as follows:

[0036] Weigh 1g of porous PGMA / EGDMA microspheres with a particle size of 5μm in a beaker, and weigh 2g of zirconium oxychloride ZrOCl 2 ·8H 2 O was fully dissolved in 3mL of water, weighed 0.5g of cerium ammonium nitrate and dissolved in 2mL of water to fully dissolve, then poured the solution of zirconium source and cerium source into the beaker containing porous PGMA / EGDMA microspheres, added 3mL of ethanol, and ultrasonically dispersed into the solution There are no obvious large particles in the. Then put it into an oven at 90° C. for 10 h to form zirconia-ceria-polymer composite microspheres. In order to remove the polymer template of the zirconia-ceria-polymer composite microsphere, the dried zircon...

Embodiment 2

[0041] The template of this example is the same as that of Example 1, except that in this example, the porous PGMA / EGDMA microsphere template has been modified with EDA to prepare the monodisperse porous zirconia-ceria composite microspheres of this example . Among them, the purpose of EDA modification is to make the surface of the polymer microspheres have amino groups. Using the coordination between amino groups and zirconium and cerium, the polymer microspheres can better interact with the zirconium and cerium sources to regulate the prepared The pore size of the porous zirconia-ceria composite microspheres and the method of EDA modification can be carried out with reference to conventional experiments. The specific preparation method of the monodisperse porous zirconia-ceria composite microspheres of this example is as follows:

[0042] Ultrasonic disperse 3g of monodisperse porous PGMA / EGDMA microspheres with a particle size of 5μm in 200mL of water, then add 6g of EDA, ...

Embodiment 3

[0048] In this example, the same template as in Example 1 was used to prepare monodisperse porous zirconia-ceria composite microspheres. The difference is that in this example, 1 g of cerium ammonium nitrate was dissolved in 2 mL of water as the cerium source solution. The remaining steps and parameters And condition is all identical with embodiment one.

[0049] Similarly, the monodisperse porous zirconia-ceria composite microspheres prepared in this example were observed by scanning electron microscopy, and the results showed that the porous zirconia-ceria composite microspheres prepared in this example had good monodispersity and particle size The diameter is uniform.

[0050] The monodisperse porous zirconia-ceria composite microspheres prepared in this example were subjected to statistical analysis of the pore size distribution using the same method as in Example 1. The results showed that the porous zirconia-ceria composite microspheres of this example had a pore diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com