Alkaline type washing method for block-shaped silicon raw materials

A silicon raw material and block technology, which is applied in the cleaning field of block silicon raw materials, can solve the problems of long cleaning cycle and achieve the effect of reducing processing difficulty, reducing processing cost and shortening cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

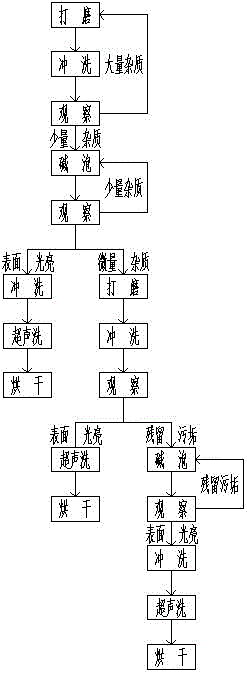

[0037] Such as figure 1 As shown, the present invention includes the following steps: 1) grinding the impurity-containing part of the bulk silicon raw material; putting the polished silicon raw material into a clear water tank for rinsing, and observing the surface of the silicon raw material after rinsing;

[0038] 2) According to observation: put the silicon raw material containing a small amount of impurities or even no impurities into the lye pool for soaking, and wash the remaining impurities and glue residue on the surface of the silicon raw material; repeat the steps for the silicon raw material containing a large amount of impurities 1) Operation;

[0039] 3) Soak the silicon raw material in the lye pool in step 2) for 15-25 minutes, and take out the silicon raw material soaked in the lye pool and observe (in this example, the immersion time of the silicon raw material is 20 minutes) ;

[0040] 4) According to observation: Put the silicon raw materials with bright surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com