Ferric salt strengthened electrokinetic remediation device for heavy metal pollution in e-waste dismantling place

An electronic waste and electrodynamics technology, applied in water pollutants, electronic waste recycling, chemical instruments and methods, etc., can solve the problems of high operation cost and complex application, reduce repair errors, improve repair efficiency, and improve electrolytic repair. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

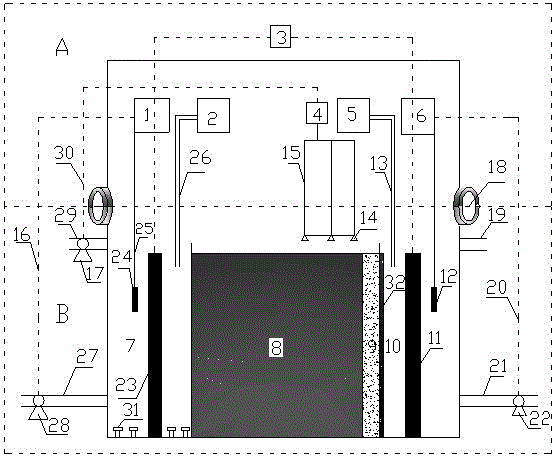

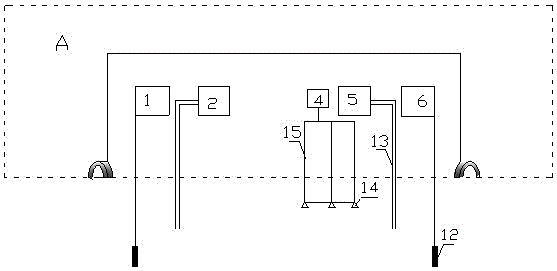

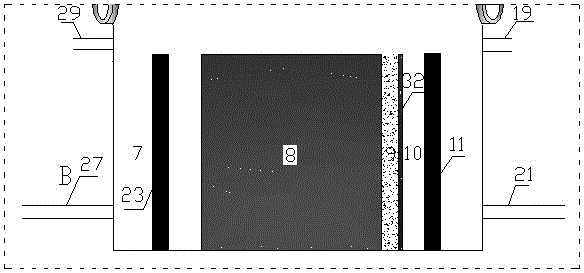

[0035] Take 3000.0 g of contaminated soil from the electronic waste dismantling site with pH value of 7.45, lead, cadmium, and zinc concentrations of 150, 15, and 750 mg / kg respectively, adjust the moisture content of the soil to 45%, and place it in the electrolytic cell. The catholyte uses 1 mol / L FeCl 3 solution, the anode is 0.5 g / L citric acid solution, and the iron salt solution is added through a constant flow pump to maintain the concentration of the electrolyte during the repair process. After repairing for 400 h, the removal rates of Pb, Cd, and Zn were 76.2%, 70.41%, and 71.23%, respectively.

Embodiment 2

[0037] Take 3000.0 g of contaminated soil from the electronic waste dismantling site with pH value of 7.45, lead, cadmium, and zinc concentrations of 150, 15, and 750 mg / kg respectively, adjust the moisture content of the soil to 45%, and place it in the electrolytic cell. The catholyte uses 3 mol / L FeCl 3 solution, the anode is 0.5 g / L citric acid solution, and the iron salt solution is added through a constant flow pump to maintain the concentration of the electrolyte during the repair process. After repairing for 400 h, the removal rates of Pb, Cd, and Zn were 79.76 %, 73.64 %, and 74.16 %, respectively.

Embodiment 3

[0039] Take 3000.0 g of contaminated soil from the electronic waste dismantling site with pH value of 7.45, lead, cadmium, and zinc concentrations of 150, 15, and 750 mg / kg respectively, adjust the moisture content of the soil to 45%, and place it in the electrolytic cell. The catholyte uses 5 mol / L FeCl 3 solution, the anode is 0.5 g / L citric acid solution, and the iron salt solution is added through a constant flow pump to maintain the concentration of the electrolyte during the repair process. After repairing for 400 h, the removal rates of Pb, Cd, and Zn were 82.46 %, 74.12 %, and 74.84 %, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com