Preparation method of graphene-enhanced titanium-based material

A titanium-based composite material and graphene technology, applied in the field of materials, can solve the problems of poor dispersion of graphene-titanium alloy mixed powder and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A preparation method of graphene-reinforced titanium-based composite material, comprising the following steps:

[0018] 1. Add 5g of graphene nanosheets into absolute ethanol, and ultrasonically disperse in absolute ethanol for 30 minutes;

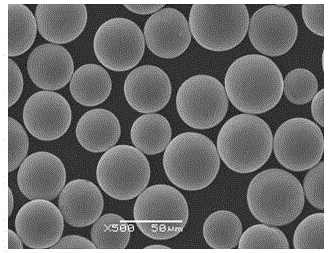

[0019] 2. Add 1000g of spherical titanium alloy powder into 4% polyvinyl alcohol for ball milling, and then add the mixed powder into graphene nanosheets for ultrasonic dispersion for 30 minutes;

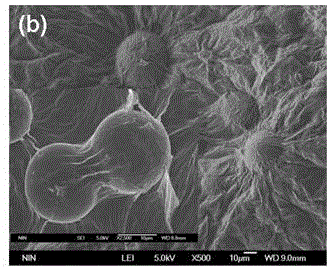

[0020] 3. Ball mill the dispersed graphene-titanium alloy mixed powder at a speed of 400 r / min, with a ball-to-material ratio of 4:1, and then perform pyrolysis reaction at 500°C;

[0021] 4 Put the titanium alloy mixed powder in step 3) into the graphite mold covered with graphite paper, put the graphite mold into the plasma sintering system, heat the graphite crucible to 1050°C at a heating rate of 200°C / min, and During the heating process, a pressure of 40 MPa is applied to the compacted powder material, and then, at a sintering tempe...

Embodiment 2

[0024] A preparation method of graphene-reinforced titanium-based composite material, comprising the following steps:

[0025] 1. Add 10g of graphene nanosheets into absolute ethanol, and ultrasonically disperse in absolute ethanol for 30 minutes;

[0026] 2. Add 1000g of spherical titanium alloy powder into 4% polyvinyl alcohol for ball milling, and then add the mixed powder into graphene nanosheets for ultrasonic dispersion for 30 minutes;

[0027] 3. Ball mill the dispersed graphene-titanium alloy mixed powder at a speed of 400 r / min, with a ball-to-material ratio of 4:1, and then perform pyrolysis reaction at 500°C;

[0028] 4 Put the titanium alloy mixed powder in step 3) into the graphite mold covered with graphite paper, put the graphite mold into the plasma sintering system, heat the graphite crucible to 1050°C at a heating rate of 200°C / min, and During the heating process, a pressure of 40 MPa is applied to the compacted powder material, and then, at a sintering temp...

Embodiment 3

[0031] A preparation method of graphene-reinforced titanium-based composite material, comprising the following steps:

[0032] 1. Add 15g of graphene nanosheets into absolute ethanol, and ultrasonically disperse in absolute ethanol for 30 minutes;

[0033] 2. Add 1000 g of spherical titanium alloy powder into 4% polyvinyl alcohol for ball milling, and then add the mixed powder into graphene nanosheets for ultrasonic dispersion for 30 minutes;

[0034] 3. Ball mill the dispersed graphene-titanium alloy mixed powder at a speed of 400 r / min, with a ball-to-material ratio of 4:1, and then perform pyrolysis reaction at 500°C;

[0035] 4 Put the titanium alloy mixed powder in step 3) into the graphite mold covered with graphite paper, put the graphite mold into the plasma sintering system, heat the graphite crucible to 1050°C at a heating rate of 200°C / min, and During the heating process, a pressure of 40 MPa is applied to the compacted powder material, and then, at a sintering tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com