Preparing method of low-reflectivity spherical copper powder for 3D printing

A low-reflectivity, 3D printing technology, applied in the field of 3D printing, can solve the problems of high reflectivity and unfavorable laser energy absorption, and achieve the effect of reducing reflectivity and improving laser energy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

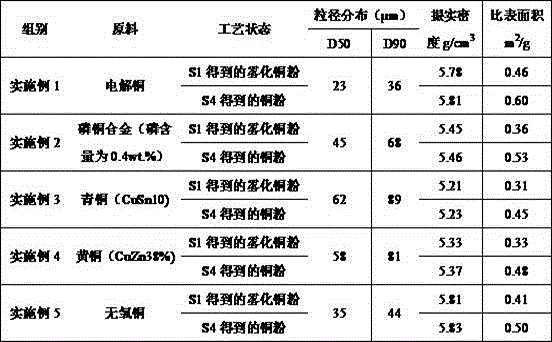

Embodiment 1

[0027] This embodiment provides a method for preparing spherical copper powder with low reflectivity for 3D printing, which at least includes the following steps:

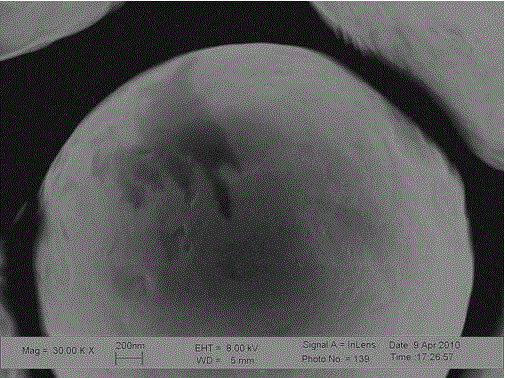

[0028] S1, using electrolytic copper as the raw material, the atomized copper powder is produced by the gas atomization method, the atomized medium gas is air, and the obtained atomized copper powder is spherical or quasi-spherical, and the particle size ranges from 5 μm to 150 μm;

[0029] S2, sieving the atomized copper powder obtained in S1, and dividing it into copper powders of different specifications;

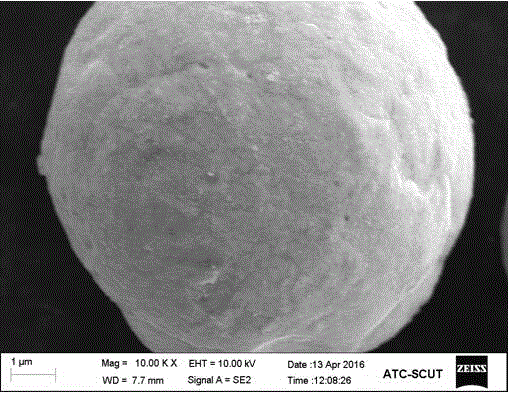

[0030] S3, put the copper powder (specification) within the range of 300-500 mesh in the crucible for oxidative roasting, so that the surface of the copper powder reacts with oxygen to form a rough surface, wherein the roasting medium is air, and the roasting temperature is 300℃, the duration of calcination is 3h, and the copper powder after calcination is brown-black;

[0031] S4, the surface oxidized coppe...

Embodiment 2

[0036] This embodiment provides a method for preparing spherical copper powder with low reflectivity for 3D printing, which at least includes the following steps:

[0037]S1, using phosphorus copper alloy (phosphorus content is 0.4wt.%) as the raw material, the atomized copper powder is produced by the gas atomization method, the atomization medium gas is air, and the atomized copper powder obtained is spherical or almost spherical, and the particle size is The range is 5μm-150μm;

[0038] S2, sieving the atomized copper powder obtained in S1, and dividing it into copper powders of different specifications;

[0039] S3, put the copper powder (specification) within the range of 300-500 mesh in the crucible for oxidative roasting, so that the surface of the copper powder reacts with oxygen to form a rough surface, wherein the roasting medium is air, and the roasting temperature is 250℃, the duration of calcination is 5h, and the copper powder after calcination is brown-black; ...

Embodiment 3

[0044] This embodiment provides a method for preparing spherical copper powder with low reflectivity for 3D printing, which at least includes the following steps:

[0045] S1, using bronze (CuSn10) as the raw material, the atomized copper powder is produced by the gas atomization method, the atomized medium gas is air, and the obtained atomized copper powder is spherical or quasi-spherical, and the particle size range is 5 μm-150 μm;

[0046] S2, sieving the atomized copper powder obtained in S1, and dividing it into copper powders of different specifications;

[0047] S3, placing copper powder (specification) within the range of 80-200 mesh in the crucible for oxidative roasting, so that the copper powder surface oxidizes with oxygen to form a rough surface, wherein the roasting medium is air, and the roasting temperature is 200℃, the duration of calcination is 5.5h, and the copper powder after calcination is brownish red;

[0048] S4, the surface oxidized copper powder obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com