A kind of preparation method of hierarchical hollow cubic tin dioxide nanoparticles

A nanoparticle, tin dioxide technology, applied in tin oxide and other directions, can solve the problems of difficult preparation of non-spherical tin dioxide, difficulty in growing and designing materials, lengthy preparation process, etc., and achieve low cost, low price and high chemical activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

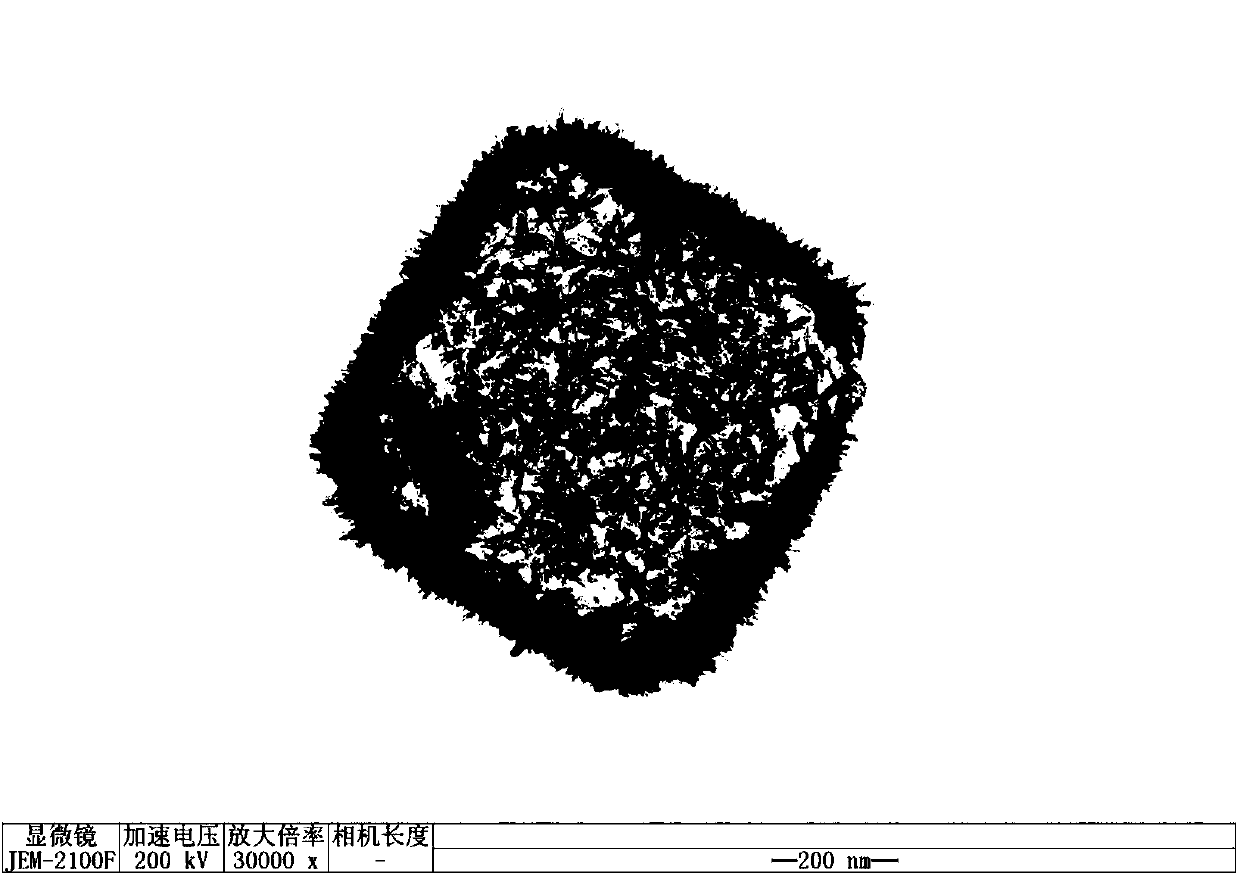

[0030] Weigh 17mg of ZnO, 240mg of NaOH, 292mg of CTAB and 210mg of SnCl 4 , then dissolve ZnO, NaOH, and CTAB with 25mL deionized water and stir for 5min, then dissolve SnCl with 5ml deionized water 4 , and then add the SnCl4 solution dropwise to the aqueous solution containing ZnO, NaOH, and CTAB, fully stir for 10 minutes and then let it stand for 24 hours, then stir the solution for 5 minutes and then transfer it to a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C for 12 hours. After the reaction, wash with deionized water and absolute ethanol for three times each, and then dry the precipitate at 60°C in an air atmosphere to collect hierarchical hollow cube-shaped tin dioxide nanoparticles composed of ultrafine nanorods. The scanned picture See attached figure 1 , the transmission scan picture is attached figure 2 .

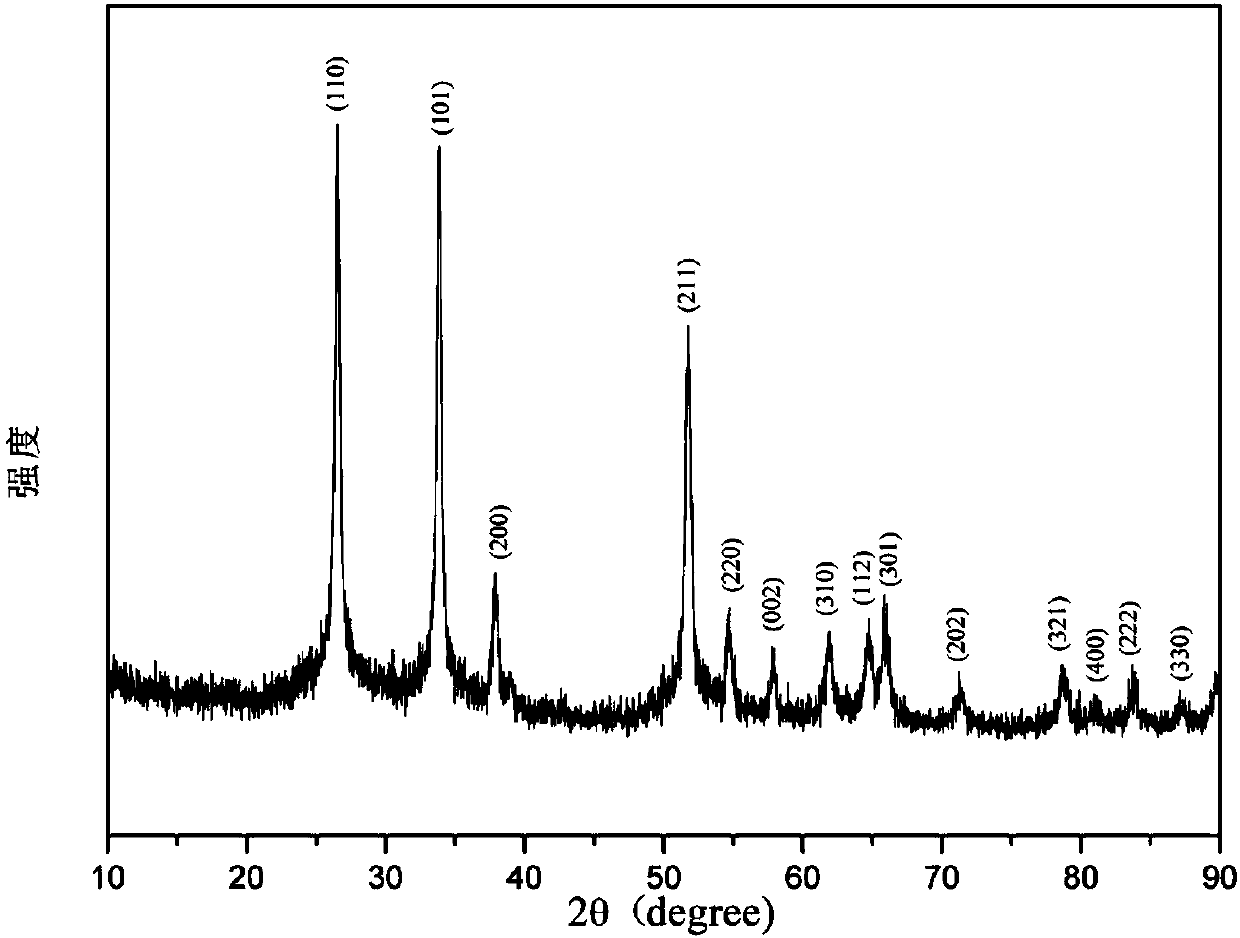

[0031] The X-ray diffraction pattern of the hierarchical hollow cube-shaped tin dioxide nanoparticles composed of one-dimensi...

Embodiment 2

[0033] Weigh 17mg of ZnO, 240mg of NaOH, 292mg of CTAB and 210mg of SnCl 4 , then dissolve ZnO, NaOH, and CTAB with 25mL deionized water and stir for 5min, then dissolve SnCl with 5ml deionized water 4 , and then add the SnCl4 solution dropwise to the aqueous solution containing ZnO, NaOH, and CTAB, stir well for 10 minutes and then let it stand for 24 hours, then stir the solution for 5 minutes and then transfer it to a hydrothermal reaction kettle for 12 hours at 200°C. After the reaction was completed, each was washed three times with deionized water and absolute ethanol, and then the precipitate was dried at 60°C in an air atmosphere, and the hierarchical hollow cubic tin dioxide nanoparticles composed of nanosheets and nanorods were collected. The scanned picture is attached Figure 5 , the transmission scan picture is attached Image 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com