Cold-rolled acid wastewater resource and zero-emission method

A technology for recycling acidic wastewater, applied in chemical instruments and methods, metallurgical wastewater treatment, iron oxide, etc. Issues such as emission reports, to achieve good social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

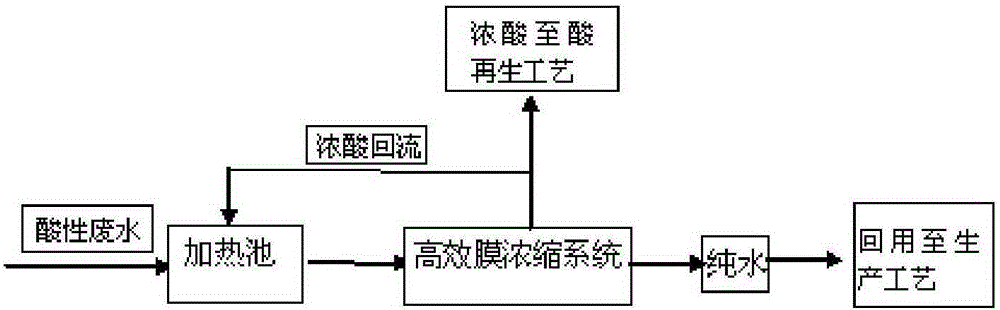

Image

Examples

Embodiment 1

[0034] Cold-rolling pickling wastewater first enters the pretreatment system for filtration to filter out particulate matter above 5-30 μm. The filtration facilities and pipelines used need to be resistant to acid corrosion. Filters with fillers such as quartz sand and anthracite can be used, or inorganic ceramic membrane filtration or sintered organic membrane filtration can be used.

[0035] The backwash water produced by the filter backwash is mixed with dilute alkali wastewater, and the suspended solids in the backwash water are also mixed into the sludge produced by dilute alkali wastewater.

[0036] Firstly, the filtered pickling wastewater is heated at 50-100°C with low-temperature steam on site, enters the water storage tank, and is lifted to the membrane module by a circulating pump. The water vapor on the acidic wastewater side passes through the membrane and enters the steam side, where it is used The vacuum pump pumps the water vapor passing through the membrane in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com