Buried type glass fiber reinforced plastic integrated sewage treatment equipment and process

A kind of sewage treatment equipment and fiberglass technology, applied in the direction of water/sewage treatment, biological water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of sewage dispersion, unstable water quality and low treatment rate, and achieve good results Nitrogen removal function, good effect of removing organic matter in sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

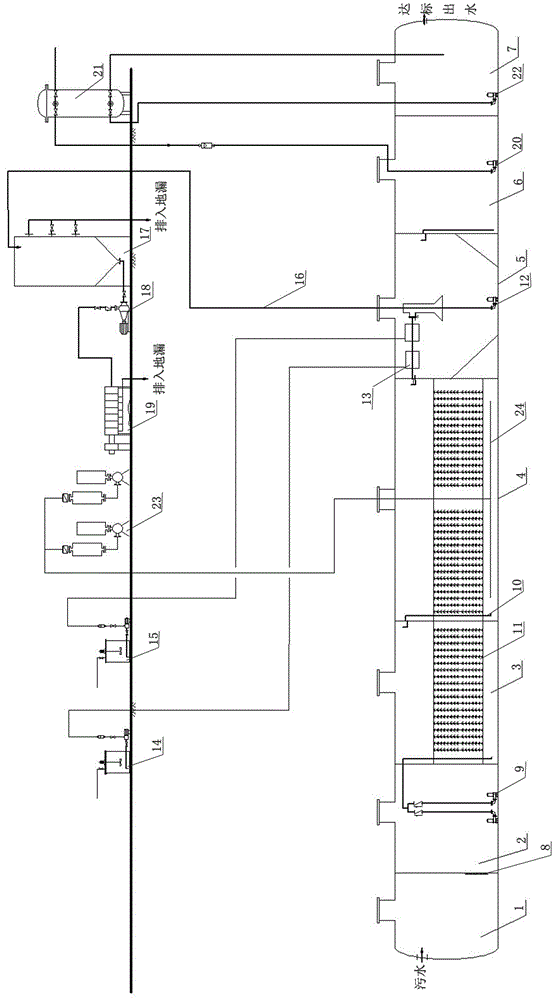

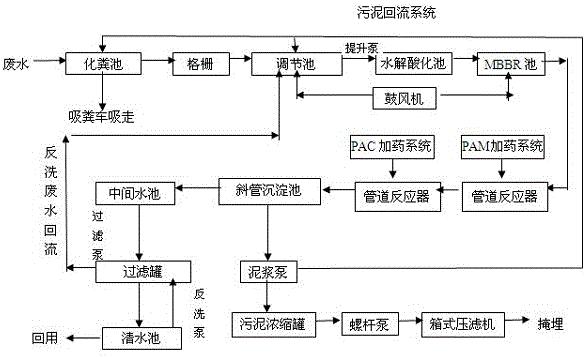

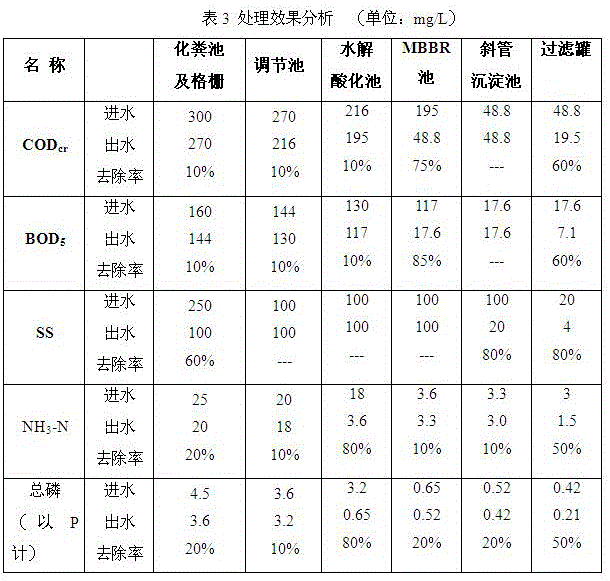

Embodiment 1

[0058] In this embodiment, the newly built sewage treatment station at the toll station of Dengtagao Expressway is taken as an example for illustration. The newly-built sewage treatment station on Dengta Expressway has a treatment capacity of 50 tons per day. The treated domestic sewage complies with the first-level standard a of the "Pollutant Discharge Standard for Urban Sewage Treatment Plants" (GB18918-2002), and the treated sewage is used as landscape water. The sewage treatment water volume of the designed sewage treatment station is 50m 3 / d, 24-hour processing, that is, 2.08m per hour 3 / h, design treatment water volume 2.2m 3 / h, the annual processing capacity is 15,800 m 3 / a. , the overall length of the equipment is 11.8m, the diameter is 2.8m, and the volume is 72.62m³; grid tank size: D (diameter) × L (length) = Φ2.8 m × 1m = 6.15m³, grid length: 1000mm, grid width: 500mm , Grille material: stainless steel mesh; adjustment tank size: D×L=Φ2.8 m×2m=12.3m³, effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com