Pouring slurry for light board

A light-duty board and grouting technology, applied in the field of grouting slurry for light-duty boards, can solve the problems that light-duty boards are difficult to take into account, and the strength cannot be guaranteed, so as to improve the anti-cracking performance, reduce the quality, and improve the stability and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The perfusion slurry for light-duty panels consists of the following raw materials in parts by weight:

[0048] Cement 90Kg;

[0049] Perlite 40Kg;

[0050] Vitrified particles 55Kg;

[0051] Latex powder 4Kg;

[0052] Fly ash 20Kg;

[0053] Gypsum powder 40Kg;

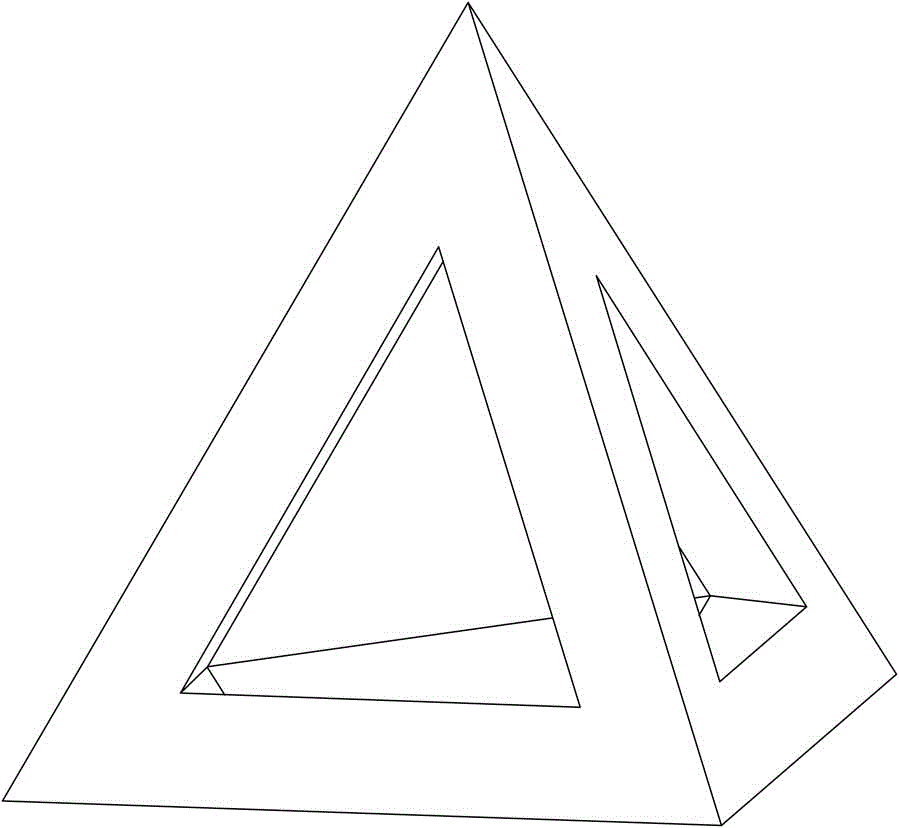

[0054] Triangular pyramid cage glass steel grain 18Kg;

[0055] Sodium carboxymethyl cellulose 2Kg;

[0056] Lignocellulose 1.2Kg;

[0057] Carbon fiber 1.3Kg;

[0059] β-cyclodextrin 5.1Kg;

[0061] Naphthalene-based water reducer 1.1Kg;

[0062] Sodium dodecylbenzenesulfonate 0.6Kg.

[0063] The preparation method of slurry is as follows:

[0064] (1) First, mix latex powder, gypsum powder, triangular pyramid cage-type glass fiber reinforced plastic particles, sodium carboxymethyl cellulose, lignocellulose, carbon fiber, cellulose ether, β-cyclodextrin, calcium formate, naphthalene-based water reducer and Sodium dodecylbenzenesulfon...

Embodiment 2

[0067] The perfusion slurry for light-duty panels consists of the following raw materials in parts by weight:

[0068] Cement 60Kg;

[0069] Perlite 50Kg;

[0070] Vitrified particles 70Kg;

[0071] Latex powder 2Kg;

[0072] Fly ash 25Kg;

[0073] Gypsum powder 30Kg;

[0074] Triangular pyramid cage glass fiber reinforced plastic particles 25Kg;

[0075] Sodium carboxymethyl cellulose 3.5Kg;

[0076] Lignocellulose 0.8Kg;

[0077] Carbon fiber 2.0Kg;

[0078] Cellulose ether 0.1Kg;

[0079] β-cyclodextrin 7.8Kg;

[0080] Calcium formate 0.05Kg;

[0081] Naphthalene-based water reducer 3.0Kg;

[0082] Sodium dodecylbenzenesulfonate 0.05Kg.

[0083] The preparation method of slurry is as follows:

[0084] (1) First, mix latex powder, gypsum powder, triangular pyramid cage-type glass fiber reinforced plastic particles, sodium carboxymethyl cellulose, lignocellulose, carbon fiber, cellulose ether, β-cyclodextrin, calcium formate, naphthalene-based water reducer and ...

Embodiment 3

[0087] The perfusion slurry for light-duty panels consists of the following raw materials in parts by weight:

[0088] Cement 120Kg;

[0089] Perlite 30Kg;

[0090] Vitrified particles 40Kg;

[0091] Latex powder 2Kg;

[0092] Fly ash 20Kg;

[0093] Gypsum powder 40Kg;

[0094] Triangular pyramid cage glass steel grain 18Kg;

[0095] Sodium carboxymethyl cellulose 2Kg;

[0096] Lignocellulose 1.2Kg;

[0097] Carbon fiber 1.3Kg;

[0098] Cellulose ether 0.5Kg;

[0099] β-cyclodextrin 2.7Kg;

[0100] Calcium formate 4.2Kg;

[0101] Naphthalene superplasticizer 5.0Kg;

[0102] Sodium dodecylbenzenesulfonate 3.5Kg.

[0103] The preparation method of slurry is as follows:

[0104] (1) First, mix latex powder, gypsum powder, triangular pyramid cage-type glass fiber reinforced plastic particles, sodium carboxymethyl cellulose, lignocellulose, carbon fiber, cellulose ether, β-cyclodextrin, calcium formate, naphthalene-based water reducer and Sodium dodecylbenzenesulfonate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com