Terahertz activated ceramic particles and preparing method thereof

A terahertz and ceramsite technology, applied in the field of special functional ceramics preparation, can solve the problems of difficulty in promoting human metabolism, low emission power of far-infrared ceramics, and difficulty in emitting far-infrared stably, so as to improve blood microcirculation and improve blood circulation. Metabolism, the effect of huge market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

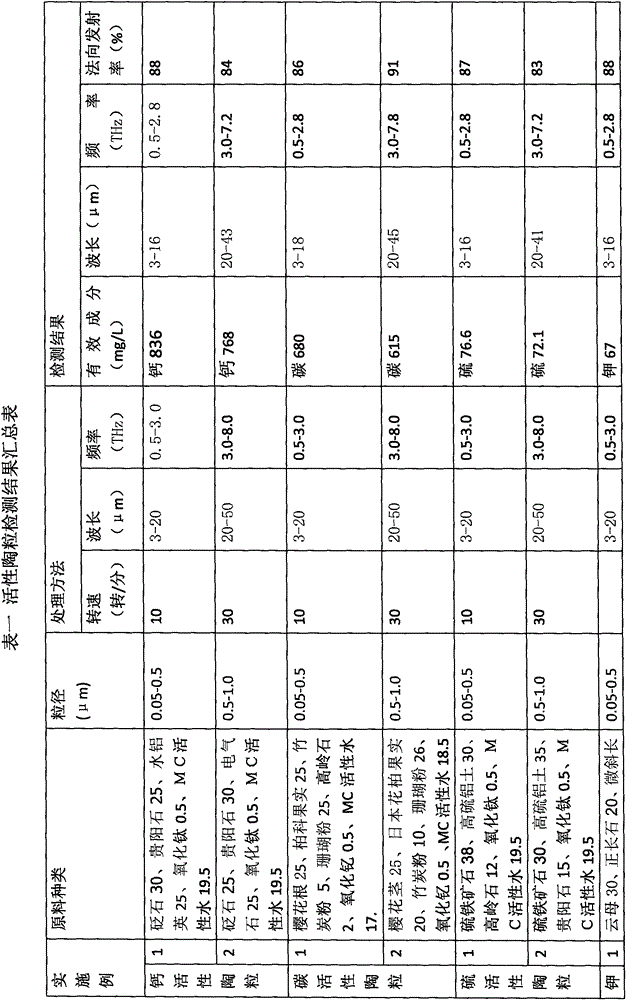

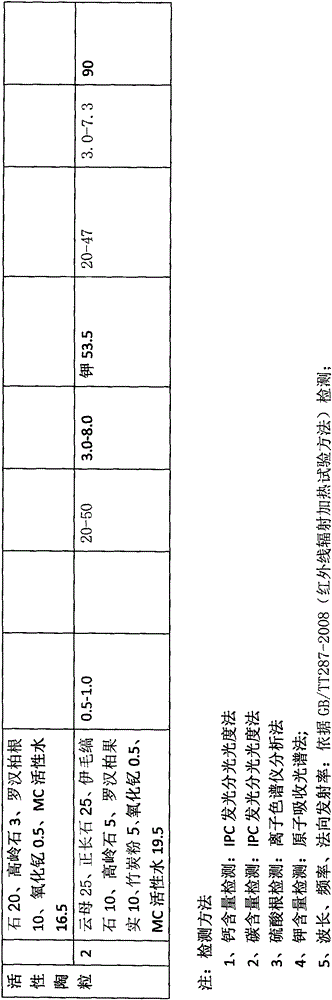

example 1

[0016] Example 1, calcining terahertz calcium active ceramsite (1), selecting ultrafine powder with a particle size of 0.05-0.5 μm, and uniformly mixing Bianstone 30, Guiyang stone 25, allophane 25, and titanium oxide 0.5 by weight percentage; Adjust the slurry with MC active water 19.5, slowly pour the slurry into a rotating conical colorless glass funnel container while stirring, the speed is 10 rpm, and the wavelength is 3-20μm and the frequency is 0.5-3.0THz The terahertz wave irradiates the conical colorless glass funnel container for 1-1.5 hours, so that the slurry can obtain the terahertz wave uniformly; the slurry treated by the terahertz wave flows into a rectangular plate with a height of 0.5-1.0cm, in which There are 0.5-1.0cm small grids. After full flow, it is dried at 120-150°C, and finally calcined at 1200°C. After cooling, it is beaten into 1.0cm ceramsite; the slurry treated with terahertz waves can also be made into Spherical ceramic balls, but the shape is n...

example 2

[0017] Example 2, Terahertz high calcium active ceramsite firing (2), select 0.5-1.0 μm particle size grade superfine powder, and uniformly mix by weight Bianstone 25, Guiyang stone 30 or tourmaline 25, and titanium oxide 0.5; MC active water 19.5 is adjusted to the slurry, and the slurry is slowly poured into a rotating conical colorless glass funnel container while stirring, and the rotation speed is 30 rpm. The hertz wave irradiates the conical colorless glass funnel container for 1-1.5 hours, so that the slurry can obtain the terahertz wave uniformly; the slurry treated by the terahertz wave flows into a rectangular plate with a height of 0.5-1.0cm, in which the There are 0.5-1.0cm small grids, which are dried at 120-150 ℃ after full flow, and finally calcined at 1200 ℃. After cooling, they are beaten into ceramsite of 0.5-1.0 cm; the slurry treated with terahertz waves can also be made into Spherical ceramic balls, but the shape is not limited to this; the calcium content...

example 3

[0018] Example 3, Terahertz carbon activated ceramsite firing (1): select ultrafine powder with a particle size of 0.05-0.5 μm, and by weight percentage 25 of the roots of Rosaceae, Cherry genus, Cherry Blossom (Cerasus sp.) plants; Japanese flower cypress [Chamaecyparispisifera (Sieb.et Zucc.) Endl root 25; Bamboo tissue powder 5, coral tissue powder 25, kaolinite 2, additive yttrium oxide 0.5 mixed well, and adjusted to slurry with MC active water 17.5 , slowly pour the slurry into a rotating conical colorless glass funnel container while stirring, the speed is 10 rpm, and at the same time, the conical colorless glass is irradiated with a wavelength of 3-20μm and a frequency of 0.5-3.0THz. The funnel container is processed for 1-1.5 hours, so that the slurry can obtain terahertz waves uniformly; the slurry treated with terahertz waves flows into a rectangular pan with a height of 0.5-1.0cm, which is provided with a small grid of 0.5-1.0cm. After it is full, it is dried at 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com