High-performance SrFe12O19/CoFe2O4 composite ferrite material and preparation method

A srfe12o19, ferrite material technology, applied in the direction of inductor/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., can solve problems such as unsatisfactory research results, improve comprehensive magnetic properties, improve mixing uniformity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

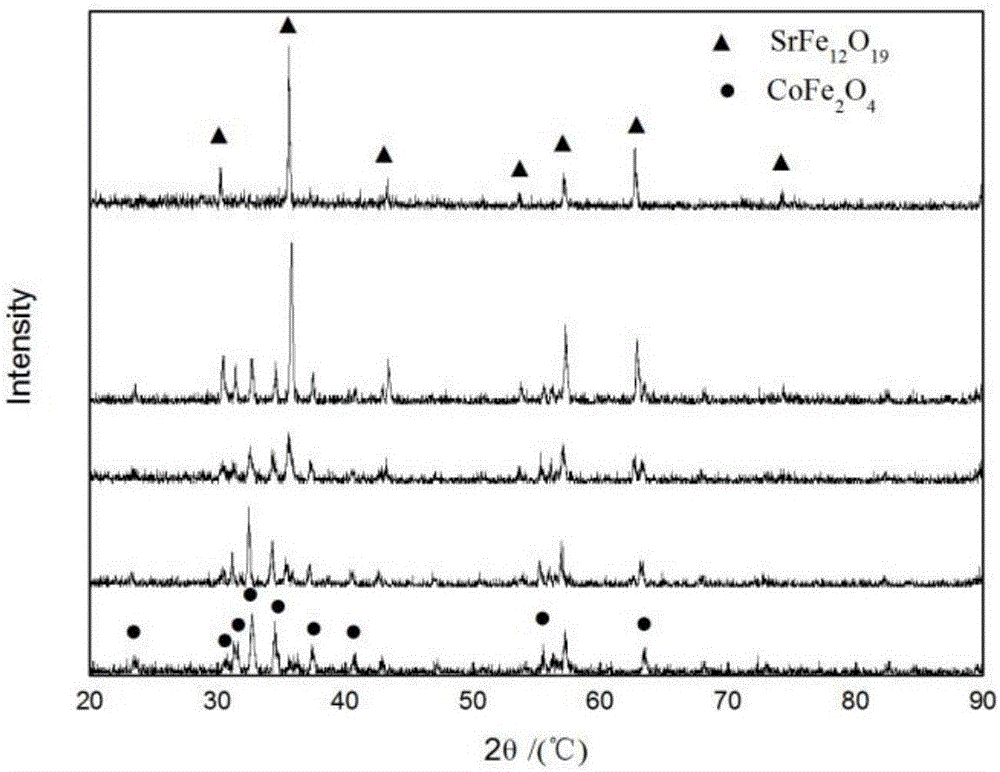

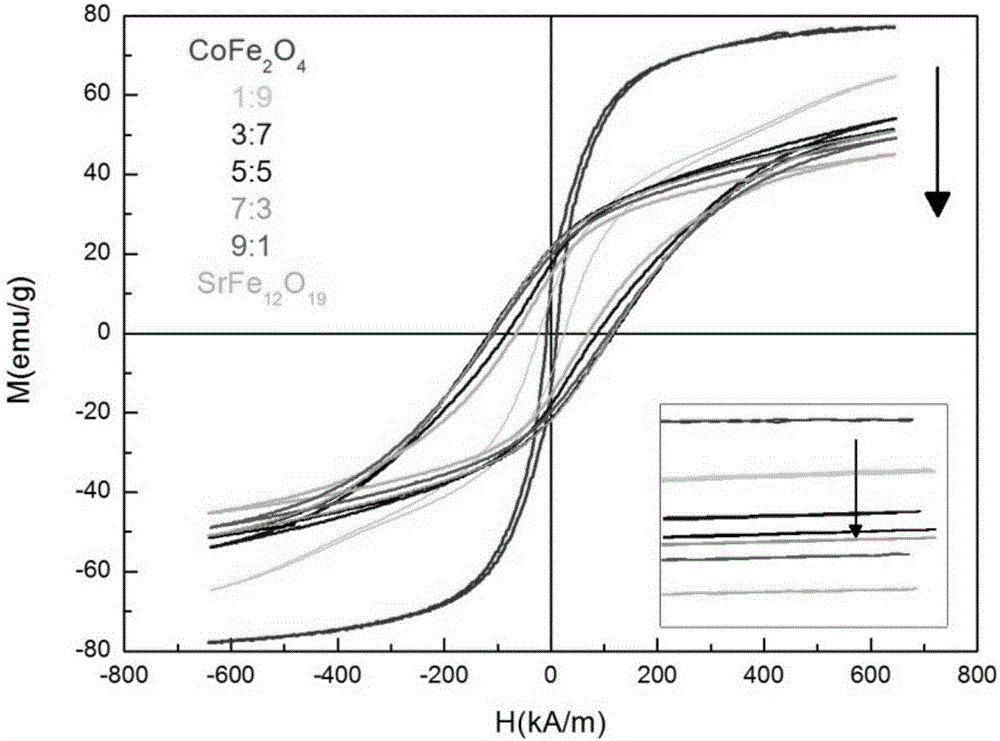

[0027] SrFe 12 o 19 with CoFe 2 o 4 Stoichiometric ratio weighing analysis of pure iron oxide (Fe 2 o 3 ), cobalt trioxide (Co 2 o 3 ), strontium carbonate (SrCO 3 ). They were respectively placed in polytetrafluoroethylene ball mill jars for ball milling at a rotational speed of 180 r / min for 5 hours, and then the ball milled mixed slurry was dried in a drying oven for 24 hours. Put it in a high-temperature box-type sintering furnace to 1000 ° C for 4 hours to obtain CoFe 2 o 4 Powder; placed in a high-temperature box-type sintering furnace to 1100 ° C for 2 hours to obtain SrFe 12 o 19 Powder.

[0028] Weigh the SrFe respectively12 o 19 Powder 5.481g, CoFe 2 o 4 Powder 0.519g, mix uniformly in a mortar, then add an appropriate amount of polyvinyl alcohol (PVA) with a mass concentration of 8% of the mixture as a binder, mix and granulate to obtain pellets, and press it into a tablet under 20MPa (diameter Φ=12.98mm, thickness d≈2mm).

[0029] The sheet materia...

Embodiment 2

[0032] SrFe 12 o 19 with CoFe 2 o 4 Stoichiometric ratio weighing analysis of pure iron oxide (Fe 2 o 3 ), cobalt trioxide (Co 2 o 3 ), strontium carbonate (SrCO 3 ). They were respectively placed in polytetrafluoroethylene ball mill jars for ball milling at a rotational speed of 180 r / min for 5 hours, and then the ball milled mixed slurry was dried in a drying oven for 24 hours. Put it in a high-temperature box-type sintering furnace to 1000 ° C for 4 hours to obtain CoFe 2 o 4 Powder; placed in a high-temperature box-type sintering furnace to 1100 ° C for 2 hours to obtain SrFe 12 o 19 Powder.

[0033] Weigh the SrFe respectively 12 o 19 Powder 5.481g, CoFe 2 o 4 Powder 0.519g, mix uniformly in a mortar, then add an appropriate amount of polyvinyl alcohol (PVA) with a mass concentration of 8% of the mixture as a binder, mix and granulate to obtain pellets, and press it into a tablet under 20MPa (diameter Φ=12.98mm, thickness d≈2mm).

[0034] The sheet mater...

Embodiment 3

[0037] SrFe 12 o 19 with CoFe 2 o 4 Stoichiometric ratio weighing analysis of pure iron oxide (Fe 2 o 3 ), cobalt trioxide (Co 2 o 3 ), strontium carbonate (SrCO 3 ). They were respectively placed in polytetrafluoroethylene ball mill jars for ball milling at a rotational speed of 180 r / min for 5 hours, and then the ball milled mixed slurry was dried in a drying oven for 24 hours. Put it in a high-temperature box-type sintering furnace to 1000 ° C for 4 hours to obtain CoFe 2 o 4 Powder; placed in a high-temperature box-type sintering furnace to 1100 ° C for 2 hours to obtain SrFe 12 o 19 Powder.

[0038] Weigh the SrFe respectively 12 o 19 Powder 2.007g, CoFe 2 o 4 Powder 3.993g, mix uniformly in a mortar, then add an appropriate amount of polyvinyl alcohol (PVA) with a mass concentration of 8% of the mixture as a binder, mix and granulate to obtain pellets, and press it into a tablet under 20MPa (diameter Φ=12.98mm, thickness d≈2mm).

[0039] The sheet mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter φ | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com