Preparation method of (S)-oxiracetam

A compound, the technology of oxirane acetamide, applied in the direction of organic chemistry and the like, can solve the problems of high production cost and low yield, and achieve the effects of low cost, high yield and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

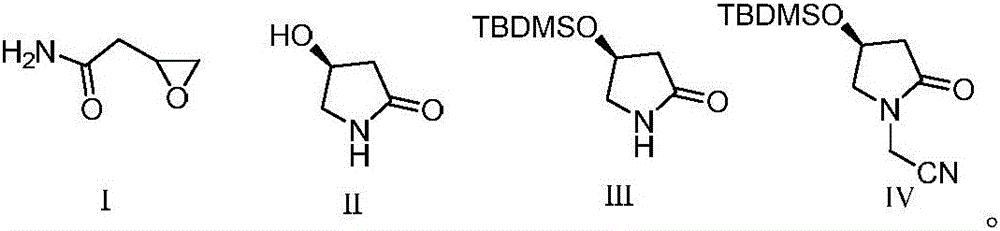

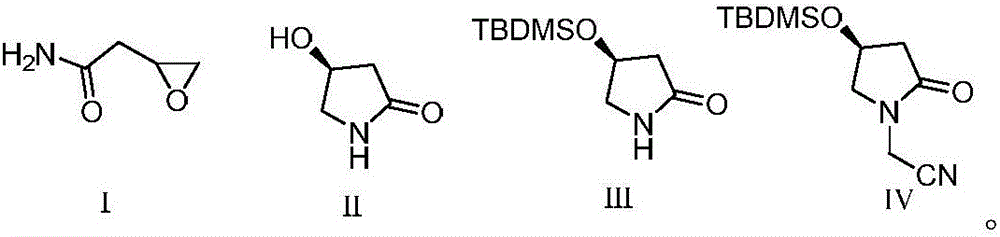

Image

Examples

Embodiment 1

[0027] Preparation of (S)-3-hydroxy-butyrolactam

[0028] Add 10.1g (100mmol) of 2-oxiranyl acetamide, 0.95g (5mmol) of CuI, and 2g (200mmol) of cesium carbonate to 150ml of methanol saturated solution of ammonia gas, and carry out a stirring reaction at 55°C for 8h, and the reaction solution reduces Concentrate under reduced pressure, add water to 100ml, extract with dichloromethane three times, wash with saturated brine three times, concentrate the ethyl acetate phase under reduced pressure, recrystallize petroleum ether to obtain (S)-3-hydroxy-butyrolactam 8.71g, yield 86.3%, HPLC purity 99.42% (area normalization method), ee value 99.67%, 1 HNMR (300MHz, DMSO-d6) δ7.23 (1H, br, s), 5.45 (1H, br, s), 4.05 (1H, m), 3.51 (1H, m), 3.40 (1H, m), 2.34 (1H,m), 2.23(1H,m).

Embodiment 2

[0030] Preparation of (S)-3-hydroxy-butyrolactam

[0031]Add 1g (10mmol) of 2-oxiranyl acetamide, 1.5g (8mmol) of CuI, and 2g (200mmol) of cesium carbonate to 13ml of saturated methanol solution of ammonia gas, stir and react at 50°C for 10h, and decompress the reaction solution Concentrate, add water to 10ml, extract three times with dichloromethane, wash with saturated brine three times, concentrate the ethyl acetate phase under reduced pressure, recrystallize petroleum ether to obtain (S)-3-hydroxy-butyrolactam 0.9g, yield 89.3%, HPLC The purity is 99.54% (area normalization method), and the ee value is 99.71%.

Embodiment 3

[0033] Preparation of (S)-3-hydroxy-butyrolactam

[0034] 10.1g (100mmol) of 2-oxiranylacetamide, 0.4g (2mmol) of CuI, and 2g (250mmol) of cesium carbonate were added to 120ml of methanol saturated solution of ammonia gas, and the reaction was stirred at 60°C for 6h, and the reaction solution reduced Concentrate under reduced pressure, add 100ml of water, extract three times with dichloromethane, wash with saturated brine three times, concentrate under reduced pressure with ethyl acetate, recrystallize from petroleum ether to obtain 8.77g of (S)-3-hydroxy-butyrolactam, yield 86.7% , HPLC purity 99.47% (area normalization method), ee value 99.69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com