Silane cross-linking low-smoke halogen-free flame retardant polyolefin elastomer material for elevator cables and preparation method

A polyolefin elastomer and silane crosslinking technology, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of unsuitable irradiation crosslinking methods and uneven wall thickness, and achieve good elasticity and flame retardancy Good performance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Silane grafted polyolefin elastomer material A:

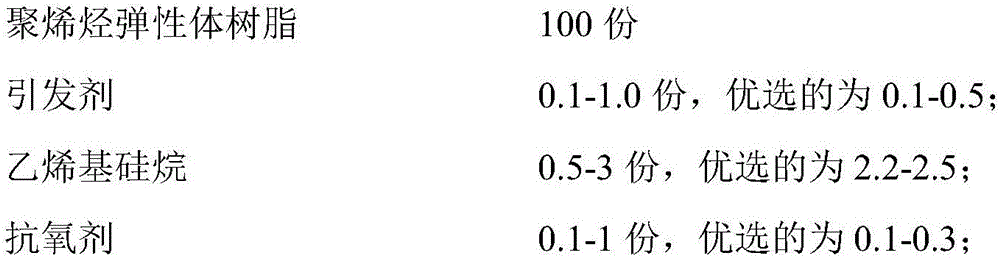

[0040] formula:

[0041]

[0042] Preparation:

[0043] will INFUSE TM Olefin block copolymers (OBC)s (Dow 9107), ethylene-hexene copolymer elastomer (Mitsui Chemicals DF840), di-tert-butyl peroxide, vinyltrimethoxysilane and antioxidant tetrakis [β- (3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, through a twin-screw extruder at 150 ° C for reaction extrusion granulation, drying after cooling, to obtain silane grafted elastic Body A material;

[0044] Low-smoke halogen-free flame-retardant polyolefin elastomer B material containing cross-linking catalyst:

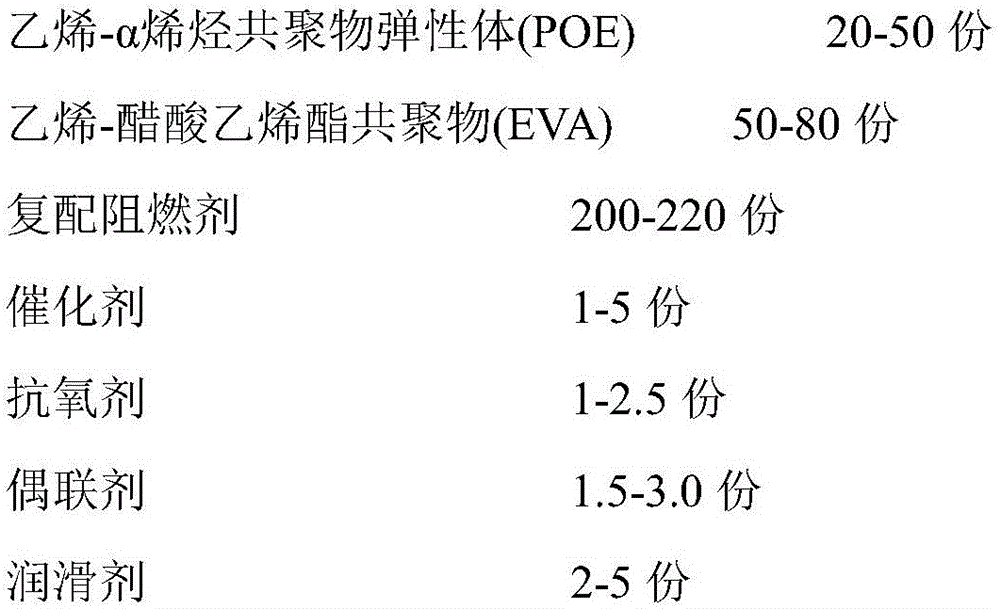

[0045] formula:

[0046]

[0047] The compound flame retardant consists of:

[0048] Aluminum hydroxide 100 parts

[0049] Magnesium hydroxide 30 parts

[0050] Zinc borate 15 parts

[0051] The vinyl acetate content is 40% ethylene-vinyl acetate copolymer (Mitsui-DuPont 40LX), ethylene-hexene copolymer elastomer (Mitsui Chemical...

Embodiment 2

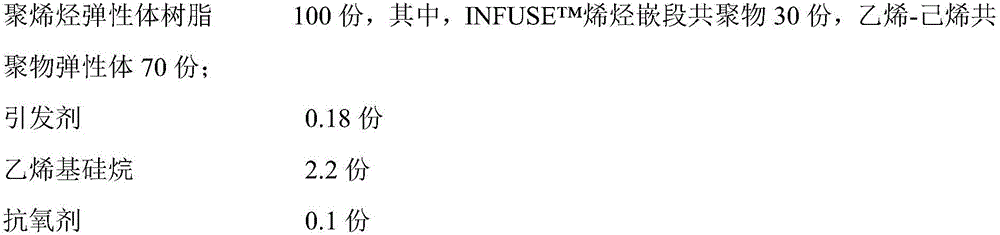

[0054] Silane grafted polyolefin elastomer material A:

[0055] formula:

[0056]

[0057] Preparation:

[0058] will INFUSE TMOlefin block copolymers (OBC)s (Dow 9007), ethylene-octene copolymer elastomers (Exxon 8203), dicumyl peroxide, vinyltrimethoxysilane and antioxidant tetrakis[β -(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, through a twin-screw extruder at 190 ° C for reaction extrusion granulation, after cooling, dry treatment to obtain silane grafted Elastomer A material;

[0059] Low-smoke halogen-free flame-retardant polyolefin elastomer B material containing cross-linking catalyst:

[0060] formula:

[0061]

[0062]

[0063] The compound flame retardant consists of:

[0064] Aluminum hydroxide 100 parts

[0065] Magnesium hydroxide 50 parts

[0066] Zinc borate 50 parts

[0067] Ethylene-vinyl acetate copolymer (TPC KA-31) with a vinyl acetate content of 28%, ethylene-octene copolymer elastomer (Dow 8411), compound flam...

Embodiment 3

[0070] Silane grafted polyolefin elastomer material A:

[0071] formula:

[0072]

[0073] Preparation:

[0074] will INFUSE TM Olefin block copolymer (OBC)s (Dow 9000) 40 parts, ethylene octene copolymer elastomer (SK Chemical 883) 60 parts, dicumyl peroxide 0.5 parts, vinyl triethoxysilane 2.2 parts 0.15 parts of antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, carried out reaction extrusion granulation by twin-screw extruder at 180°C, cooled Carry out drying treatment afterward, obtain silane grafted elastomer A material;

[0075] Low-smoke halogen-free flame-retardant polyolefin elastomer B material containing cross-linking catalyst:

[0076] formula:

[0077]

[0078] The antioxidant is a 1:1 mixture of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol and dilauryl thiodipropionate;

[0079] 1.7 parts of coupling agent

[0080] Lubricant 3 parts

[0081] The compound flame retardant consis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com