Magnesium seal solitary crystal air flue anion spray as well as preparation method and application thereof

A technology of negative ions and negative ion powder, which is applied in the field of negative ion spray and its preparation, can solve the problems of difficult protection and great harm to the human body, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

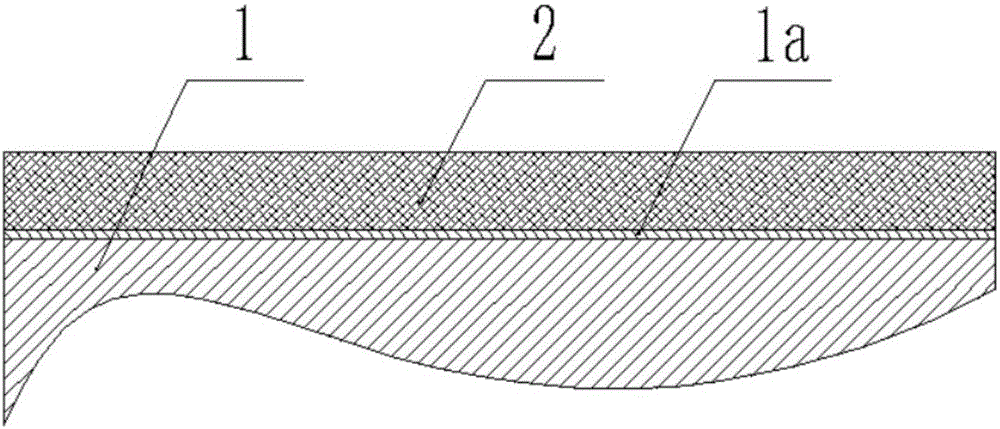

Image

Examples

preparation example Construction

[0041] A preparation method of magnesium cylindrical air duct anion spray, comprising the steps of:

[0042] (1) Under normal temperature and pressure, add the synthetic resin emulsion of formula quantity 1 / 2-2 / 3, and the pigment and filler of formula quantity, negative ion powder and paraffin (nano bamboo charcoal powder) in the high-pressure grinding device successively, with 1000 Stirring, grinding and dispersing into suspension paddles at -3000r / min speed;

[0043] (2) uniformly add the synthetic resin emulsion of surplus in the high-pressure grinding device, after stirring and dispersing with the rotating speed of 1000-3000r / min, vibrate and filter;

[0044] (3) Evenly add the thickener, preservative and silver ions in the prescribed amount, stir and disperse evenly at a speed of 1000-3000r / min, and then pack.

[0045] Among them, the high-pressure grinding device is a patented product of our company, and its patent number is "CN203842640U". Driven by a high-pressure pum...

Embodiment 1

[0049] A magnesium seal square crystal air duct negative ion spray, which contains the following components by weight: pigments and fillers: 0.2kg, negative ion powder: 35kg, paraffin wax: 5kg, synthetic resin emulsion: 57kg, thickener: 0.5kg, anti-corrosion Agent: 0.2kg, silver ion: 2.1kg;

[0050] The preparation method of described magnesia square crystal air duct negative ion spray comprises the steps:

[0051] (1) Under normal temperature and pressure, 38kg of synthetic resin emulsion, and 0.2kg of pigments and fillers, 35kg of negative ion powder and 5kg of paraffin are added to the high-pressure grinding device in turn, and stirred and ground at a speed of 1000r / min to form a suspension paddle;

[0052] (2) uniformly add 19kg of synthetic resin emulsion in the high-pressure grinding device, after stirring and dispersing at a rotating speed of 1200r / min, vibrate and filter;

[0053] (3) Evenly add 0.5kg of thickener, 0.2kg of preservative and 2.1kg of silver ions, stir ...

Embodiment 2

[0056] A magnesium seal square crystal air duct negative ion spray, which contains the following components by weight: pigments and fillers: 18kg, negative ion powder: 16kg, paraffin wax: 10kg, synthetic resin emulsion: 51kg, thickener: 1.2kg, preservative : 0.8kg, silver ion: 3kg;

[0057] The preparation method of described magnesia square crystal air duct negative ion spray comprises the steps:

[0058] (1) Under normal temperature and pressure, add 34kg of synthetic resin emulsion, and 18kg of pigments and fillers, 16kg of negative ion powder and 10kg of paraffin into the high-pressure grinding device in turn, and stir and grind at a speed of 1500r / min to disperse into a suspension paddle;

[0059] (2) uniformly add 17kg of synthetic resin emulsion in the high-pressure grinding device, after stirring and dispersing at a rotating speed of 1000r / min, vibrate and filter;

[0060] (3) Evenly add 1.2kg of thickener, 0.8kg of preservative and 3kg of silver ions, stir and disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com