Water-based polyether coupling agent and preparation method thereof

A technology of coupling agent and polyether, which is applied in the fields of cleaning agent, metalworking fluid for forming process, processing, and metal cutting. It can solve the problems of insolubility, reduce the alkalinity of the system, and poor coupling effect, so as to reduce production costs and facilitate addition. The effect of simple, strong coupling capabilities

- Summary

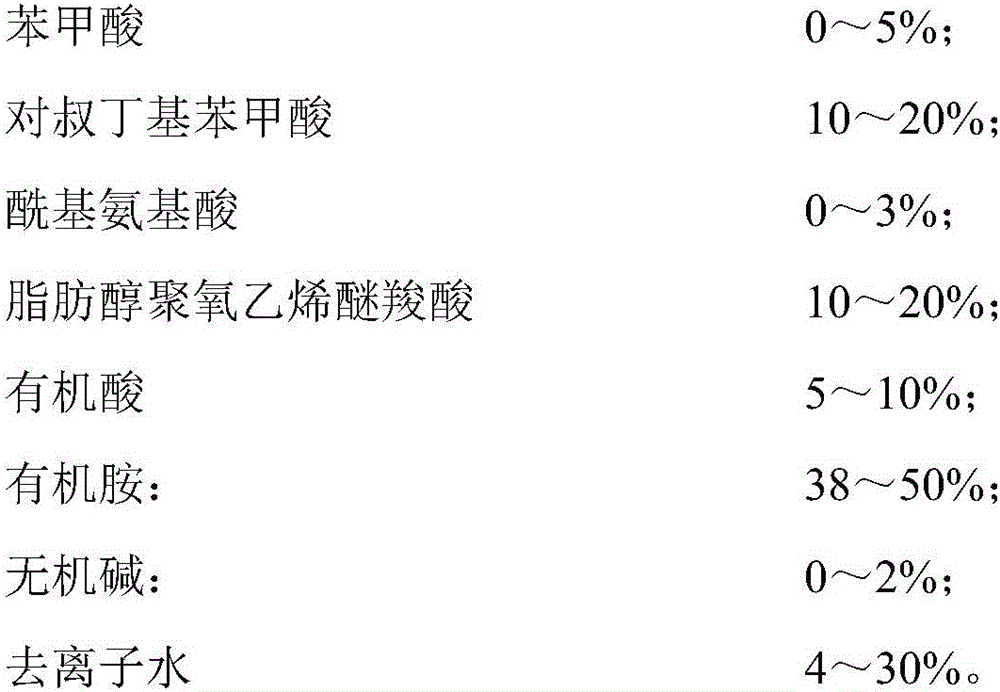

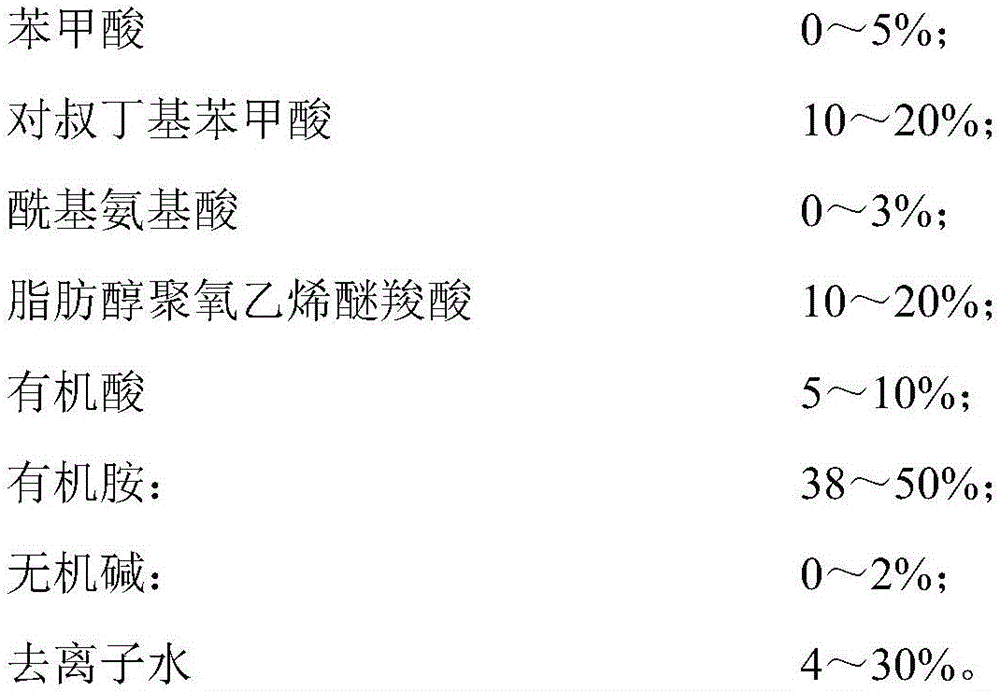

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

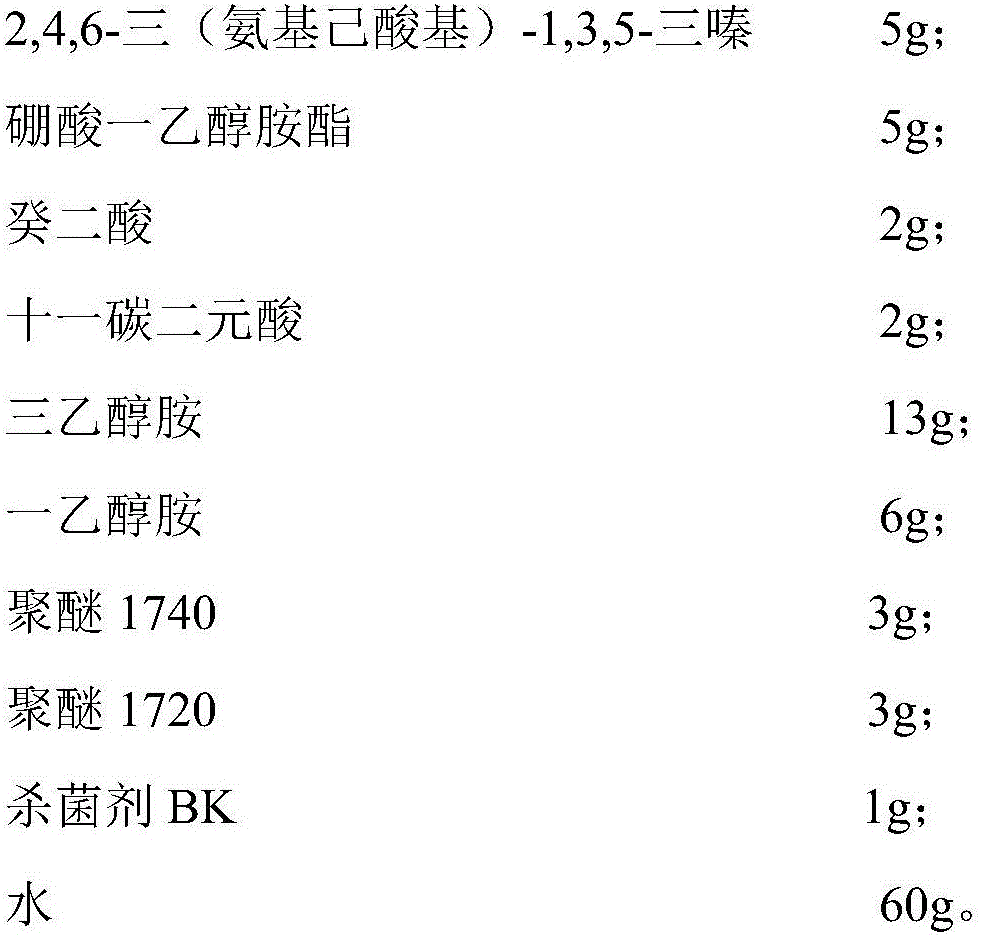

Examples

Embodiment 1

[0021] The present embodiment prepares water-based polyether coupling agent as follows:

[0022] Weigh 22kg of deionized water, 30kg of polyetheramine D230, and 10kg of triethanolamine into the reaction kettle, turn on the stirring, heat up to 80°C, and keep a constant temperature; then add 10kg of p-tert-butylbenzoic acid, 3kg of N- Acyl amino acid, 15kg fatty alcohol polyoxyethylene ether carboxylic acid (RO(CH 2 CH 2 O) 10 CH 2 COONa, R is C 12 Alkyl), 10kg of dimer acid (dimer acid containing 36 carbons), and then stirred for 60 minutes to obtain a water-soluble polyether coupling agent.

Embodiment 2

[0024] The present embodiment prepares water-based polyether coupling agent as follows:

[0025] Weigh 30kg of deionized water, 18kg of polyetheramine D2000, and 20kg of triethanolamine into the reaction kettle, turn on the stirring, heat up to 80°C, and keep a constant temperature; then add 5kg of benzoic acid and 10kg of p-tert-butylbenzoic acid while stirring , 3kg N-acyl amino acid, 10kg fatty alcohol polyoxyethylene ether carboxylic acid (RO(CH 2 CH 2 O) 10 CH 2 COONa, R is C 14 Alkyl), 5kg of dimer acid (dimer acid containing 21 carbons), stirred and reacted for 60 minutes to obtain a water-soluble polyether coupling agent.

Embodiment 3

[0027] The present embodiment prepares water-based polyether coupling agent as follows:

[0028] Weigh 30kg of deionized water, 10kg of polyetheramine D2000, 30kg of triethanolamine, and 2kg of potassium hydroxide into the reaction kettle, turn on the stirring, heat up to 80°C, and keep constant temperature; then add 20kg of p-tert-butylbenzene while stirring Formic acid, 15kg fatty alcohol polyoxyethylene ether carboxylic acid (RO(CH 2 CH 2 O) 10 CH 2 COONa, R is C 12 Alkyl group), 10kg n-octanoic acid, stirred and reacted for 60 minutes to obtain a water-soluble polyether coupling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com