High-strength, high-electric-conductivity and high-stress relaxation-resistance copper alloy elastic material and preparation method thereof

A stress relaxation, elastic material technology, applied in high strength, high stress relaxation resistance copper alloy elastic material and its preparation, high conductivity field, can solve the problem of difficult to meet the use requirements of automotive high current relays and connectors, low conductivity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

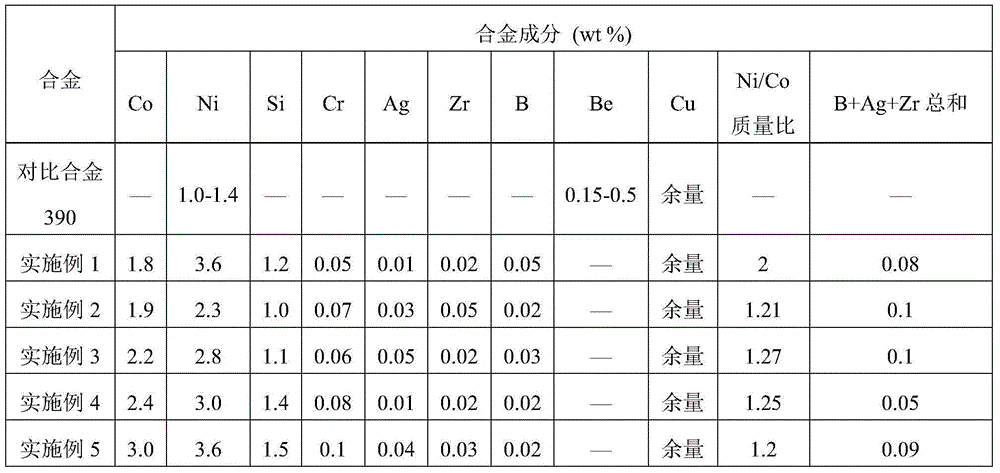

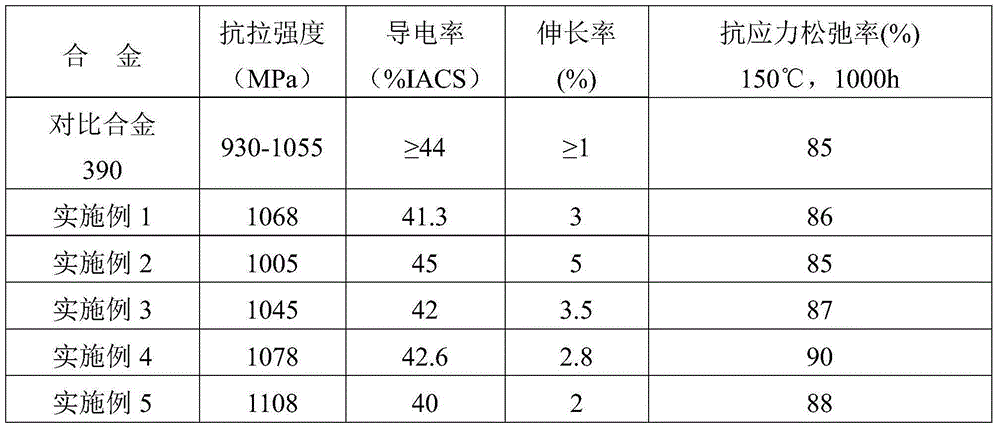

[0030] The alloy of the invention adopts the following raw materials for smelting: electrolytic copper, electrolytic nickel, electrolytic cobalt, pure silicon, pure silver, Cu-5wt%Cr, Cu-10wt%Zr and Cu-B master alloy. The composition of the alloy is shown in Example 1 of Table 1.

[0031] 1. Melting: Add electrolytic copper, electrolytic nickel, electrolytic cobalt, pure silicon, pure silver, Cu-5wt%Cr, Cu-10wt%Zr and Cu-B master alloy into the boron oxide crucible, raise the temperature to 1250℃, After the electrolytic copper is melted, vacuumize, the vacuum degree is less than 0.1Pa, and then nitrogen gas is introduced. After the melt is completely melted, it is evenly stirred and then cast. The casting temperature is 1150°C.

[0032] 2. Homogenization heat treatment: The alloy is subjected to homogenization heat treatment at a temperature of 920°C, the holding time is 8 hours, and the cooling method is water cooling.

[0033] 3. Hot rolling: the alloy is heated at 850°C, t...

Embodiment 2

[0041] The alloy of the invention adopts the following raw materials for smelting: electrolytic copper, electrolytic nickel, electrolytic cobalt, pure silicon, pure silver, Cu-5wt%Cr, Cu-10wt%Zr and Cu-B master alloy. The composition of the alloy is shown in Example 2 of Table 1.

[0042] 1. Melting: Add electrolytic copper, electrolytic nickel, electrolytic cobalt, pure silicon, pure silver, Cu-5wt%Cr, Cu-10wt%Zr and Cu-B master alloy into the boron oxide crucible, raise the temperature to 1270℃, After the electrolytic copper and copper are melted, vacuumize, the vacuum degree is less than 0.1Pa, and then nitrogen gas is introduced. After the melt is completely melted, it is evenly stirred and then cast. The casting temperature is 1170°C.

[0043] 2. Homogenization heat treatment: The alloy is subjected to homogenization heat treatment at a temperature of 940°C, the holding time is 10h, and the cooling method is water cooling.

[0044] 3. Hot rolling: the alloy is heated at ...

Embodiment 3

[0052] The alloy of the invention adopts the following raw materials for smelting: electrolytic copper, electrolytic nickel, electrolytic cobalt, pure silicon, pure silver, Cu-5wt%Cr, Cu-10wt%Zr and Cu-B master alloy. The composition of the alloy is shown in Example 3 of Table 1.

[0053] 1. Melting: Add electrolytic copper, electrolytic nickel, electrolytic cobalt, pure silicon, pure silver, Cu-5wt%Cr, Cu-10wt%Zr and Cu-B master alloy into the boron oxide crucible, raise the temperature to 1300℃, After the electrolytic copper and copper are melted, vacuumize, the vacuum degree is less than 0.1Pa, and then nitrogen gas is introduced. After the melt is completely melted, it is evenly stirred and then cast. The casting temperature is 1200°C.

[0054] 2. Homogenization heat treatment: The alloy is subjected to homogenization heat treatment at a temperature of 960°C, the holding time is 8 hours, and the cooling method is water cooling.

[0055] 3. Hot rolling: the alloy is heated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com