Carbonitriding heat treatment technique under new atmosphere

A process method, carbonitriding technology, applied in the field of heat treatment, can solve the problems of poor economy, long carbonitriding heat treatment cycle, coarse carbides, etc., to achieve short cycle, shorten heat treatment process, shorten heat treatment The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the carbonitriding heat treatment process of described new atmosphere is as follows:

[0021] (1) The equipment adopts UBE-1200 multi-purpose furnace.

[0022] (2) Carburizing medium: nitrogen + methanol + ammonia + propane; use oxygen probe to control carbon potential, control CO content to 20% (full content of carburizing medium), ammonia gas flow rate is 0.32m 3 / h, nitrogen about 4m 3 / h, methanol is about 4.4L / h, and the flow rate of propane is automatically controlled by an oxygen probe to realize the control of the carbon potential of the furnace atmosphere;

[0023] (3) Loading method: load 3 layers / pan, select the number of loading layers according to the height of the workpiece, the distance between the height direction of the workpiece and the diameter of the upper tray is 30mm; each layer is separated by a net, each layer Keep a gap of 6mm between the workpieces to ensure the uniformity of the permeation layer.

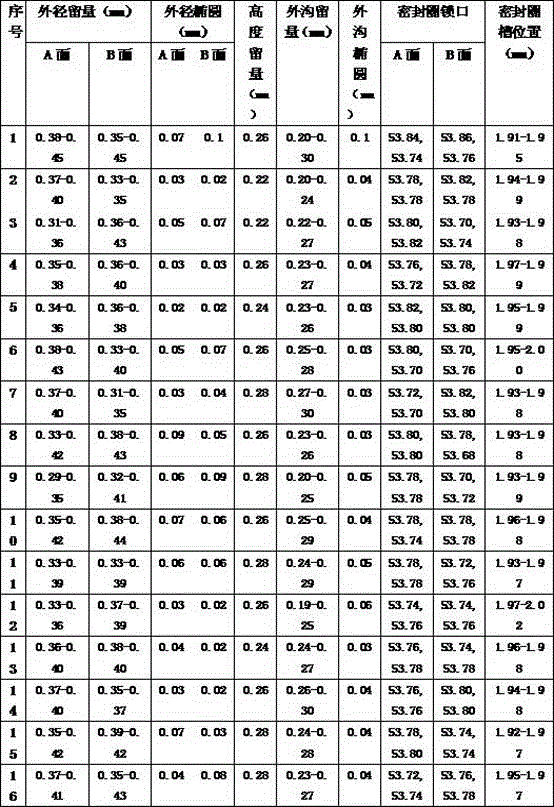

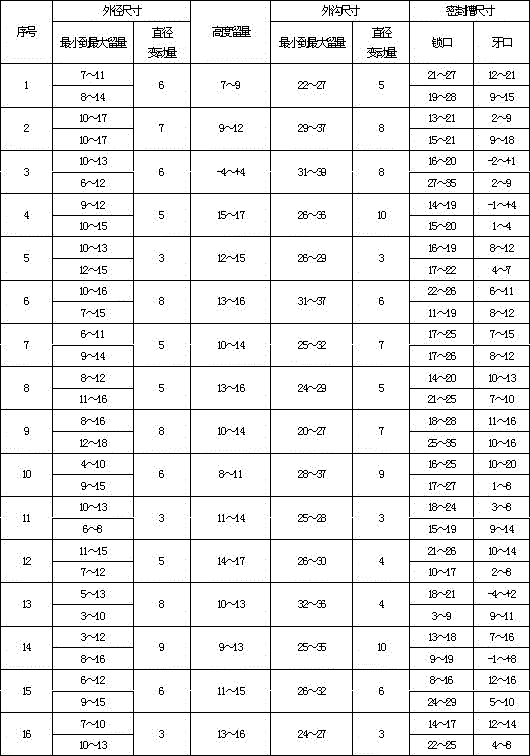

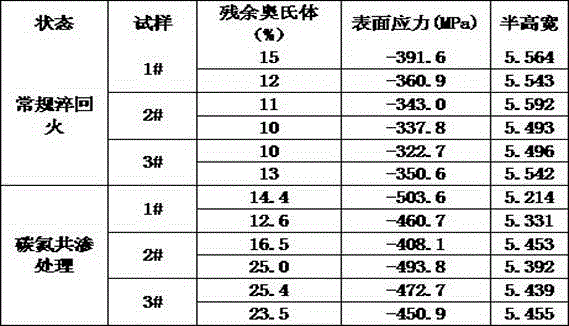

[0024] (4) Process parameter...

Embodiment 2

[0026] Embodiment 2: the carbonitriding heat treatment process of described new atmosphere is as follows:

[0027] (1) The equipment adopts UBE-1200 multi-purpose furnace.

[0028] (2) Carburizing medium: nitrogen + methanol + ammonia + propane; use an oxygen probe to control the carbon potential, control the CO content to 19.5%, and the ammonia flow rate to 0.32m 3 / h, nitrogen about 4.1m 3 / h, methanol is about 4.2L / h, and the flow rate of propane is automatically controlled by an oxygen probe to realize the control of the carbon potential of the furnace atmosphere;

[0029] (3) Loading method: load 3 layers / pan, select the number of loading layers according to the height of the workpiece, the distance between the height direction of the workpiece and the diameter of the upper tray is 30mm, and each layer is separated by a net. Keep a gap of 6 mm between the workpieces to ensure the uniformity of the permeation layer.

[0030] (4) Process parameters: carbonitriding temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com