Auxiliary gas-phase cross-linking method of electron beams

A gas-phase cross-linking and electron beam technology, which is applied to fiber types, textiles and papermaking, and fiber processing, can solve the problems of low production efficiency and difficulty in uniform cross-linking, and achieve high production efficiency, short cross-linking time, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

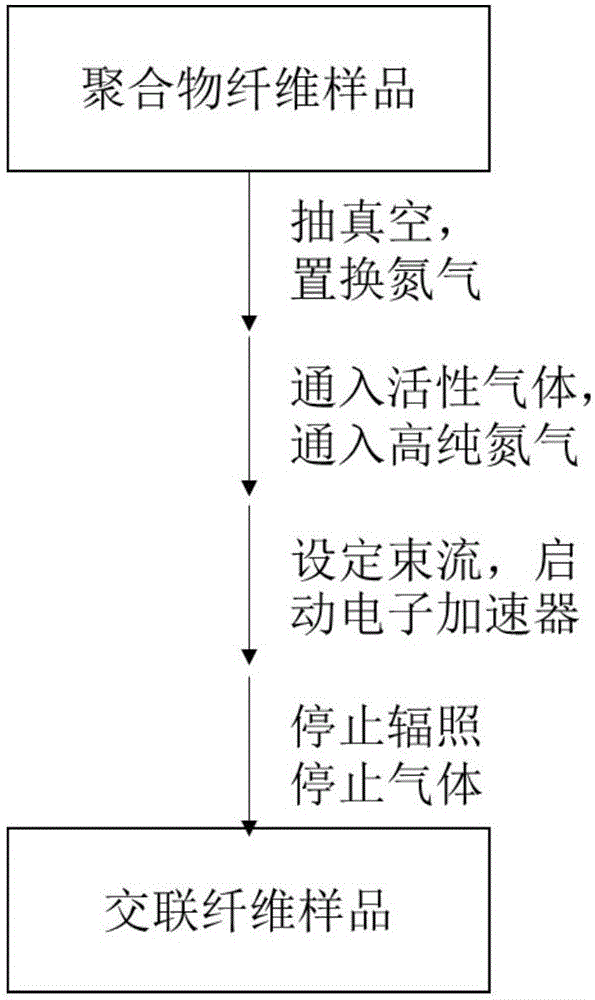

Method used

Image

Examples

Embodiment 1

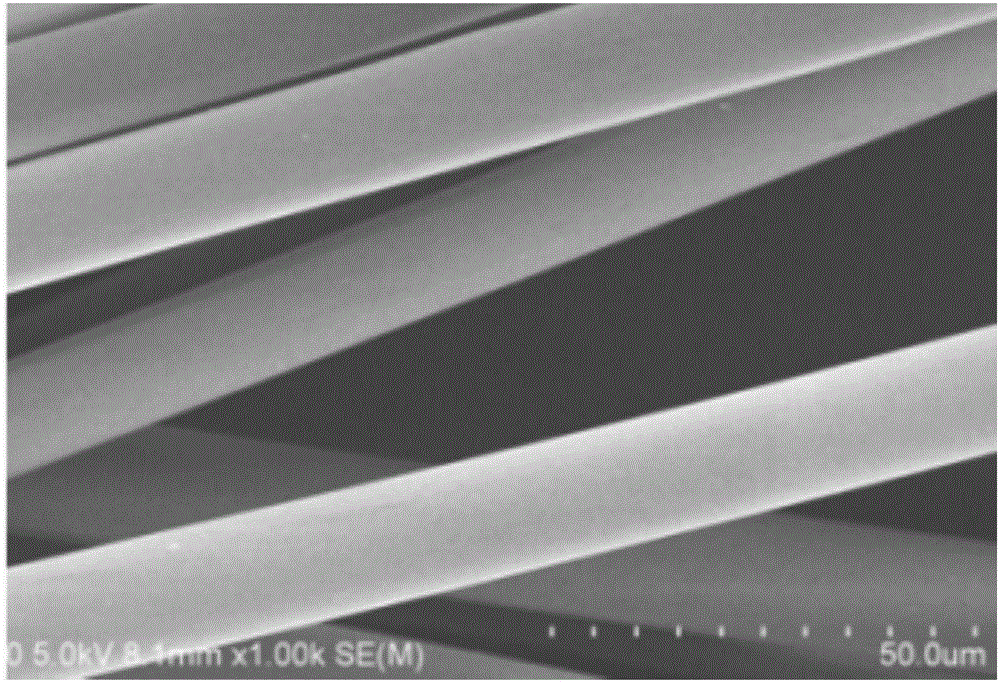

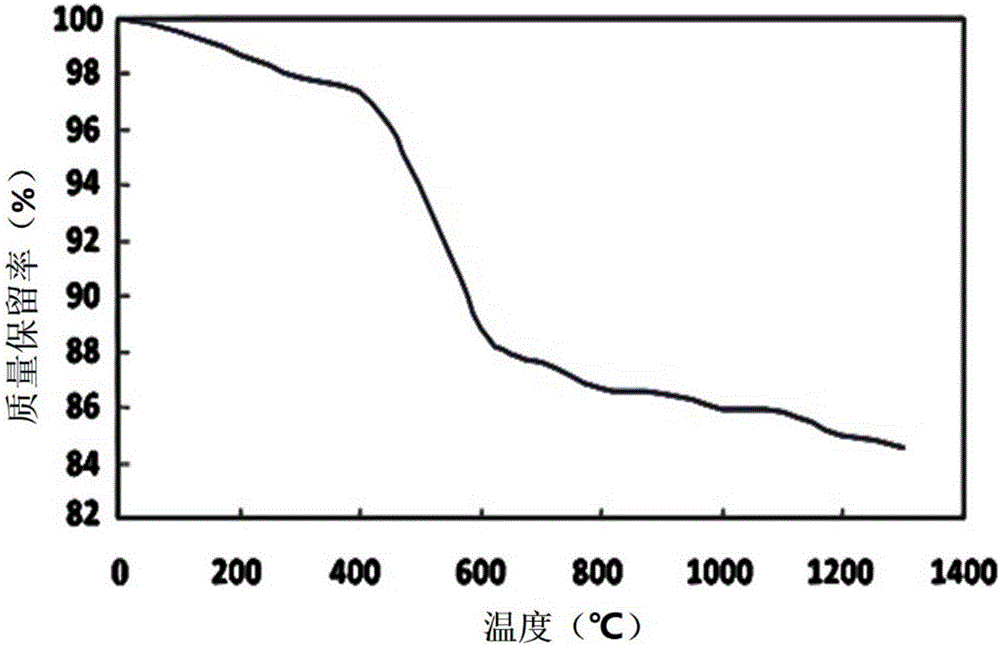

[0019] (1) With 100 grams of polycarbosilane fiber samples, the diameter of the fiber filament is 14 microns, vacuumize and replace high-purity nitrogen, and repeat twice; (2) feed 1,3-butadiene and high-purity nitrogen respectively, 1 , the flow rate of 3-butadiene is 300L / h, and the flow rate of high-purity nitrogen gas is 300L / h; (3) the polycarbosilane fiber rotates in the device under the bundle, and the rotation speed is 5rad / min; (4) start the electron accelerator, the beam The current density is 1kGy / s, the irradiation is 3h, the cumulative irradiation dose is 10.8MGy, and the irradiation is stopped. The cross-linked fiber gel content reaches 95%, the oxygen content is 0.8wt%, and the thermal weight loss at 1000°C in nitrogen is 16% (attached figure 2 ), the micrographs of the crosslinked fiber show that the surface and interface are smooth and dense (attached image 3 ).

Embodiment 2

[0021] (1) Vacuumize 100 grams of polysilazane fiber samples with a fiber filament diameter of 18 microns to replace high-purity nitrogen, and repeat twice; (2) feed dichlorosilane and high-purity nitrogen respectively, with a flow rate of 100 L / h, the flow rate of high-purity nitrogen gas is 500L / h; (3) the polycarbosilane fiber rotates in the device under the beam, and the rotation speed is 10rad / min; (4) start the electron accelerator, the beam density is 0.5kGy / s, and the irradiation After 5 hours, the cumulative radiation dose was 9MGy, and the radiation was stopped. The cross-linked fiber has a gel content of 91%, an oxygen content of 1.2wt%, and a thermal weight loss of 13% at 1000°C in nitrogen.

Embodiment 3

[0023] (1) Take 100 grams of polyborosilazane fiber samples, the diameter of the fiber filament is 15 microns, vacuumize and replace high-purity nitrogen, and repeat twice; (2) feed dichlorosilane and high-purity nitrogen respectively, with a flow rate of 100L / h, the flow rate of high-purity nitrogen gas is 300L / h; (3) the polycarbosilane fiber rotates in the device under the beam, and the rotation speed is 20rad / min; (4) start the electron accelerator, the beam density is 1.5kGy / s, and the radiation After 2 hours of irradiation, the cumulative irradiation dose was 10.8MGy, and the irradiation was stopped. The gel content of the cross-linked fiber reaches 94%, the oxygen content is 1.5wt%, and the thermal weight loss at 1000°C in nitrogen is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com