Ship waste gas denitration system

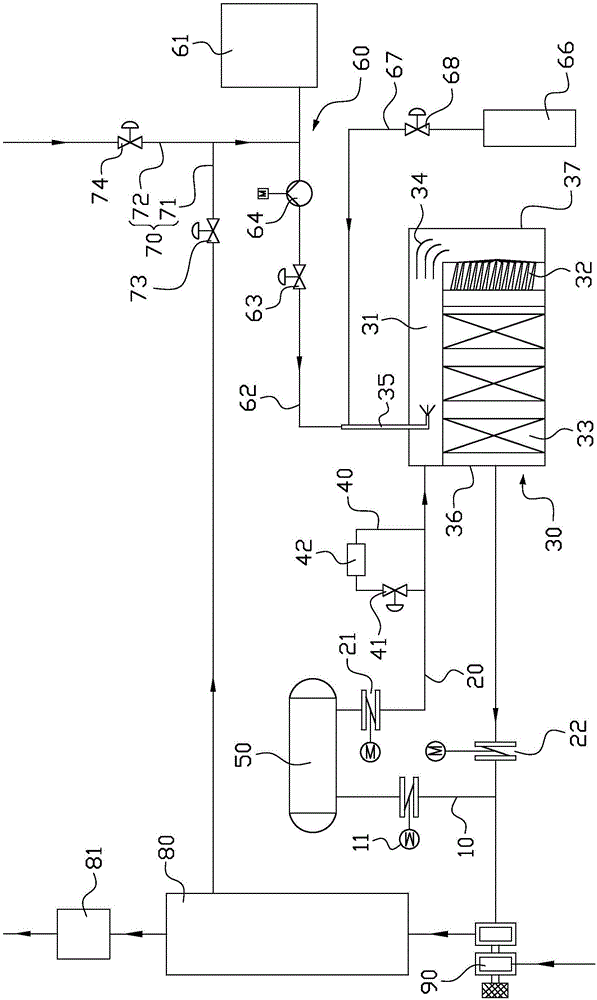

An exhaust gas and denitration technology, applied in the field of ship exhaust gas denitration system, can solve the problems of other equipment arrangement, complex structure and large space occupied that affect the movement space of people on board, so as to achieve compact structure, reduce the setting of connecting parts, and shorten the length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Carry out exhaust gas denitration treatment on diesel engine of model A: exhaust gas is discharged from the diesel engine to the exhaust gas collecting box, and 1 / 4 of the exhaust gas is drawn from the exhaust gas denitration pipeline to be oxidized and discharged into the denitration reactor. At this time, the urea solution is in the metering pump Under the action, it enters into the urea evaporation chamber and decomposes into ammonia gas. The mixed gas enters the mixer laterally under the action of the baffle for rotating mixing. The mixed gas enters the reaction chamber to undergo catalytic reduction reaction. The reacted gas Enter the turbocharger, then enter the waste heat boiler and muffler, and finally discharge to the atmosphere.

[0041] After the denitration process is over, the flushing water enters the hot water pipeline connected to the waste heat boiler. The water is heated, and the flow of hot water into the cold water pipeline is changed by adjusting the si...

Embodiment 2

[0043] Exhaust gas denitration treatment is performed on diesel engines of model A: exhaust gas is discharged from the diesel engine to the exhaust gas collecting tank, and 1 / 2 of the exhaust gas is drawn from the exhaust gas denitration pipeline to be oxidized and discharged into the denitration reactor. At this time, the urea solution is in the metering pump Under the action, it enters into the urea evaporation chamber and decomposes into ammonia gas. The mixed gas enters the mixer laterally under the action of the baffle for rotating mixing. The mixed gas enters the reaction chamber to undergo catalytic reduction reaction. The reacted gas Enter the turbocharger, then enter the waste heat boiler and muffler, and finally discharge to the atmosphere.

[0044] After the denitration process is over, the flushing water enters the hot water pipeline connected to the waste heat boiler. The water is heated, and the flow of hot water into the cold water pipeline is changed by adjusting t...

Embodiment 3

[0046] Exhaust gas denitrification treatment for diesel engine of model A: Exhaust gas is discharged from the diesel engine to the exhaust gas collecting tank, and 1 / 8 of the exhaust gas is drawn from the exhaust gas denitration pipeline to be oxidized and discharged into the denitration reactor. At this time, the urea solution is in the metering pump Under the action, it enters into the urea evaporation chamber and decomposes into ammonia gas. The mixed gas enters the mixer laterally under the action of the baffle for rotating mixing. The mixed gas enters the reaction chamber to undergo catalytic reduction reaction. The reacted gas Enter the turbocharger, then enter the waste heat boiler and muffler, and finally discharge to the atmosphere.

[0047] After the denitration process is over, the flushing water enters the hot water pipeline connected to the waste heat boiler. The water is heated, and the flow of hot water into the cold water pipeline is changed by adjusting the sixth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com