Method for determining urease based on nano copper oxide

A technology of nano-copper oxide and urease, which is applied in the field of analytical chemistry and nanometers to achieve the effects of less sample demand, good reproducibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] The specific preparation steps of nano-copper oxide are as follows: (1) Take 150 ml of 0.02 mol / L copper acetate solution and 0.5 ml of glacial acetic acid into a three-necked flask equipped with a condenser, stir and heat to boiling; (2) Quickly add 0.04 g / ml sodium hydroxide solution 10 ml, continue to stir for 5 minutes after the addition, to obtain a black copper oxide precipitate; (3) centrifuge the black copper oxide precipitate obtained from the reaction, wash with absolute ethanol three times, and dry under reduced pressure, that is A nano-copper oxide powder with a diameter of 6 nm was obtained.

example 2

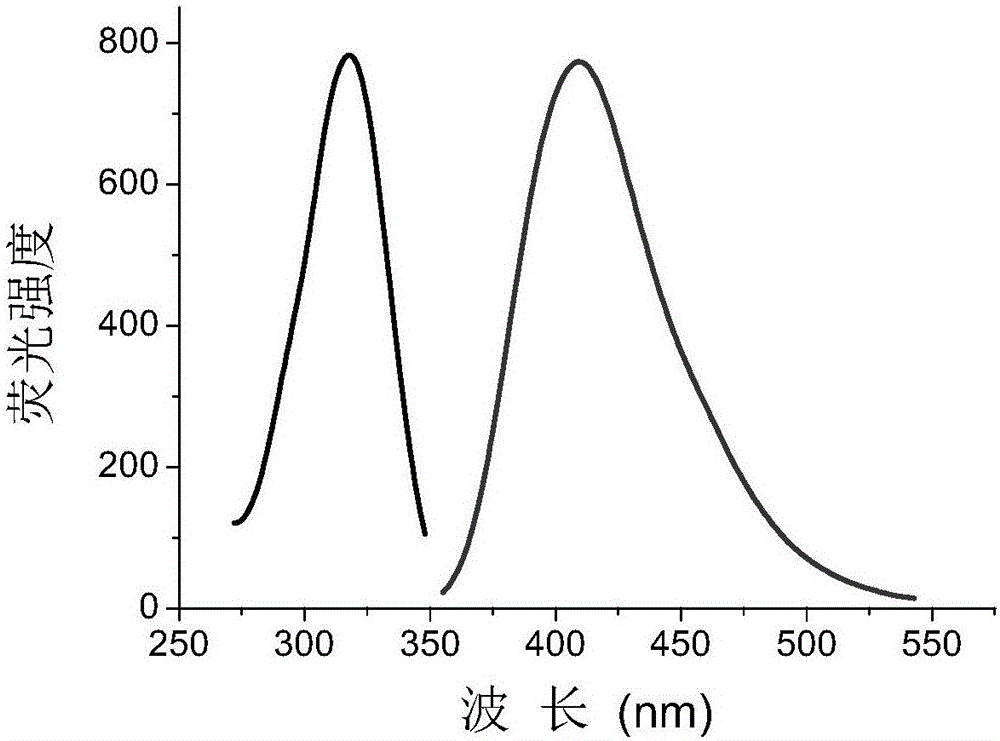

[0047] 50 µL concentration of 120 mmol / L hydrogen peroxide solution, 50 µL concentration of 80 mmol / L p-hydroxyphenylpropionic acid and 200 µL concentration of 2 mg / L nano-copper oxide solution prepared in Example 1 were added to 700 µL In a phosphate buffer solution (pH 10.25) with a concentration of 100mmol / L, mix and shake well, place in a warm bath at 65°C, and measure the fluorescence spectrum after 15 minutes. Such as figure 1 As shown, the excitation wavelength of the fluorescent product is 320 nm, and the emission wavelength is 409 nm.

example 3

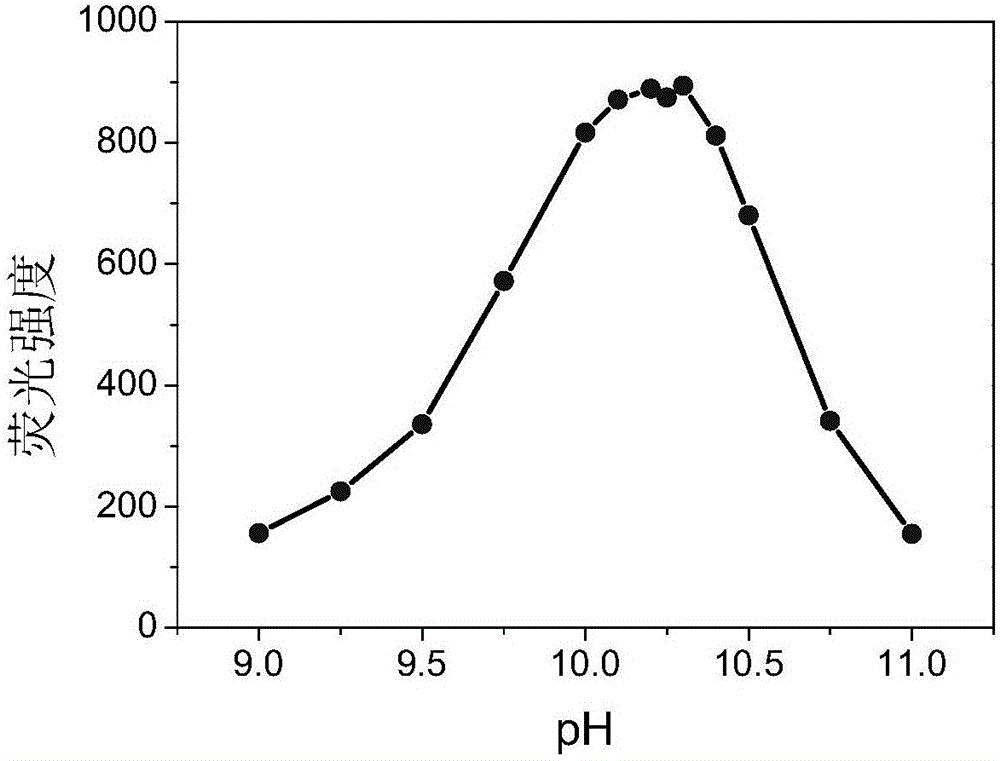

[0049] Add 50 µL concentration of 120 mmol / L hydrogen peroxide solution, 50 µL concentration of 80 mmol / L p-hydroxyphenylpropionic acid and 200 µL concentration of 2 mg / L nano-copper oxide prepared in Example 1 to a concentration of 700 µL 100mmol / L and different pH phosphate buffer solutions (pH 9-11), mix and shake well and place in a warm bath at 65°C, measure the fluorescence intensity at 409 nm after 15 minutes (excitation wavelength is 320 nm). Such as figure 2 As shown, the fluorescence intensity reaches the maximum value at pH 10.1~10.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com