Optimization method of cooling curve in vacuum brazing process of flat cracked antenna

A cracked antenna and cooling curve technology, which is applied in the field of optimization of the cooling curve in the vacuum brazing process of the flat cracked antenna, can solve the problems that it is difficult to guide the design of the manufacturing process, and the cooling curve stays in the analysis stage, so as to ensure the electrical performance and increase the shape , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Specific embodiments of the present invention will be described in detail below.

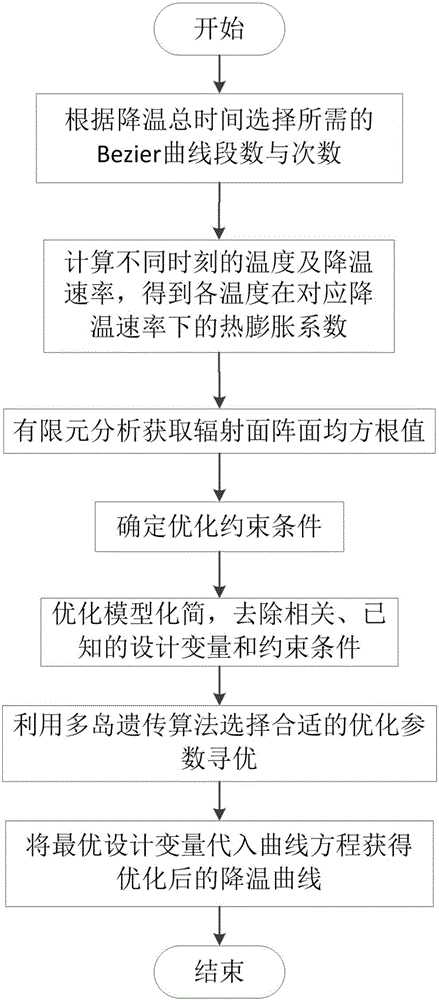

[0053] refer to figure 1 , a method for optimizing the cooling curve in the vacuum brazing process of flat plate slit antenna, the concrete steps are as follows:

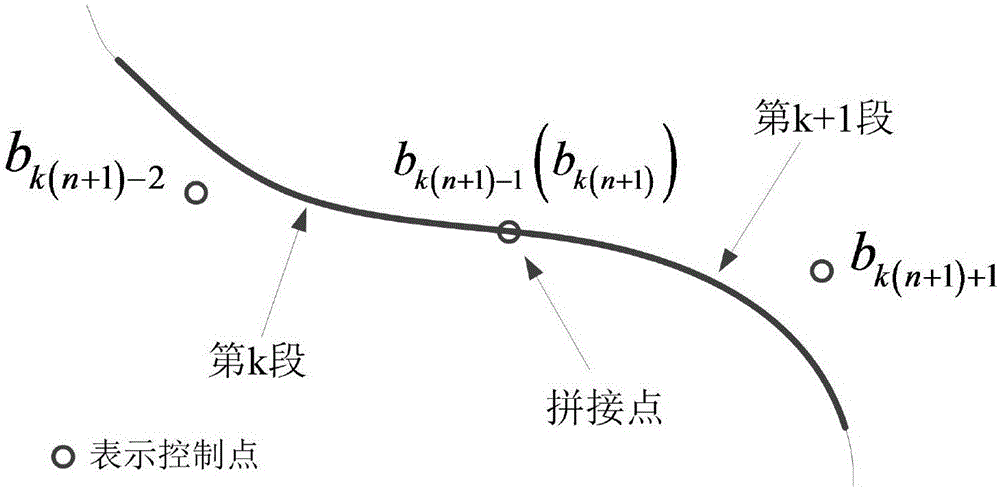

[0054] (1) According to the total cooling time TIME, select the appropriate number of Bezier curve segments m and times n, and determine the number of control points m (n+1), so that the control points are evenly distributed along the time axis. The temperature of the coordinates is the design variable, and the temperature design variable b is expressed as

[0055] find b=[b 0 ,b 1 ,... b m·(n+1)-1 ] T

[0056] where b i (i=0~m·(n+1)-1) is the ordinate of the control point;

[0057] At this time, the cooling curve can be expressed as

[0058]

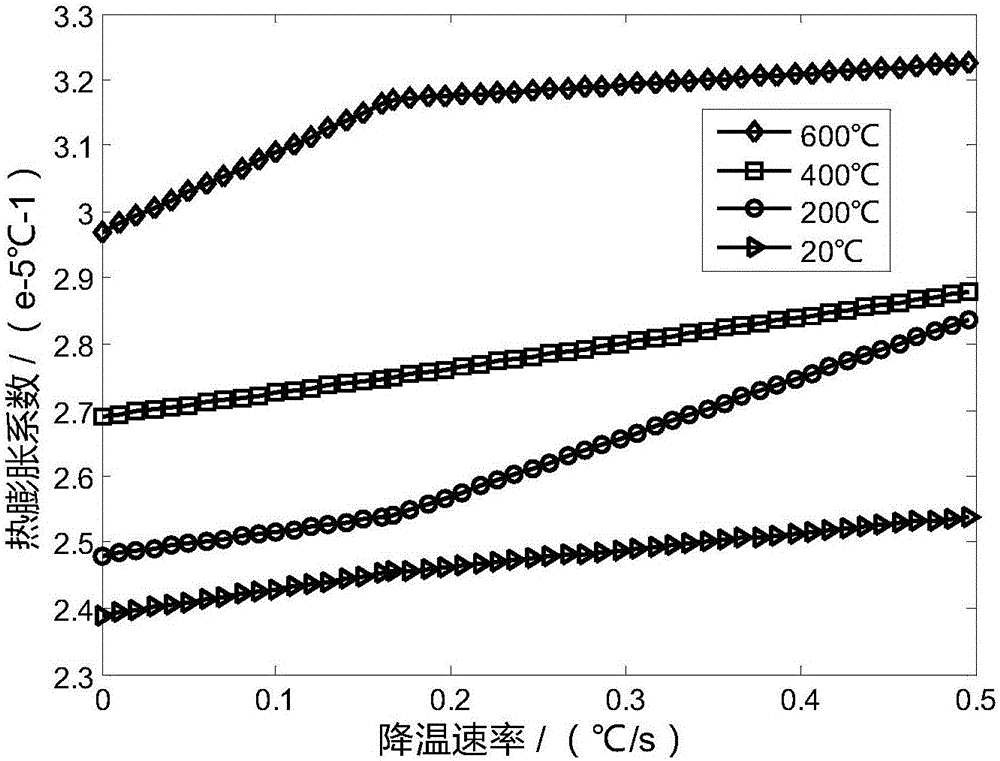

[0059] (2) Calculate the temperature and cooling rate at different times according to the cooling curve, and determine the thermal expansion coefficients of the base metal an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com