High-performance negative electrode directly serving as lithium ion battery and battery using the negative electrode

A lithium-ion battery, high-performance technology, applied in the direction of electrode manufacturing, battery electrodes, negative electrodes, etc., can solve the problems of lithium-ion battery capacity reduction, safety hazards, battery short circuit, etc., achieve excellent cycle stability, improve conductivity, The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Preparation of CuO thin film: select 20 μm thick Cu foil as the current collector Cu foil, pickle the surface of the Cu foil with 1.0 mol / L hydrochloric acid, and then clean it with deionized water; place the cleaned Cu foil in In a closed tube furnace, dry at room temperature for 1.5 h under the protection of argon. The temperature of the closed tube furnace was raised to 300 °C at a rate of 10 °C / min, and then oxygen was introduced at a flow rate of 40 mL / min. After room temperature, a CuO thin film was obtained on the surface of current collector Cu foil.

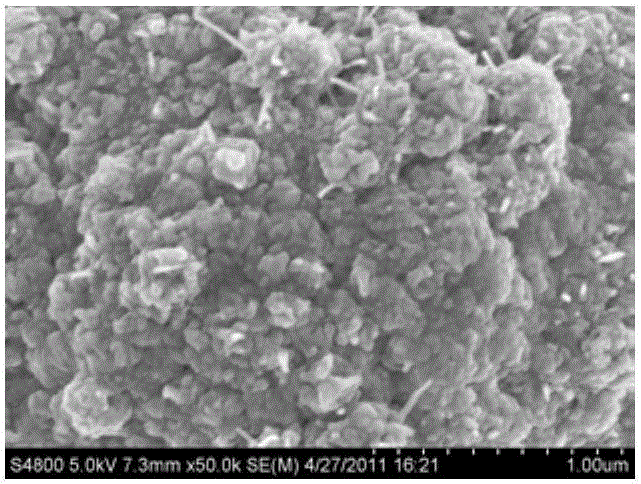

[0041] Morphology of CuO thin film: observe the morphology of the prepared CuO thin film by scanning electron microscope, the scanning electron microscope picture is shown in Figure 1a . It can be seen from the figure that the CuO particles have certain gaps, and there are small short rod-like structures in the direction perpendicular to the surface of the Cu foil.

[0042] Preparation of lithium-ion battery nega...

Embodiment 2

[0047] Preparation of CuO thin film: select Cu foil with a thickness of 20 μm as the current collector Cu foil, pickle the surface of the Cu foil with 0.5 mol / L hydrochloric acid, and then clean it with deionized water; put the cleaned Cu foil in the air After natural drying, it was placed in a closed tube furnace. The temperature of the closed tube furnace was raised to 250 °C at a rate of 5 °C / min, and then oxygen was introduced at a flow rate of 50 mL / min. A CuO thin film was obtained on the surface of the fluid Cu foil.

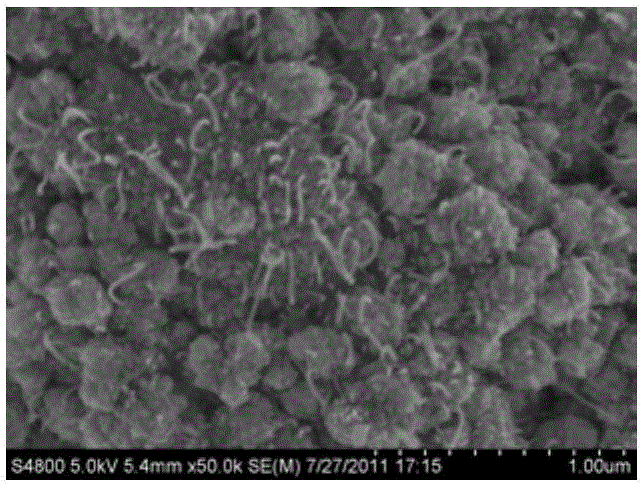

[0048] Morphology of CuO thin film: observe the morphology of the prepared CuO thin film by scanning electron microscope, the scanning electron microscope picture is shown in Figure 1b . It can be seen from the figure that the particle size is small and uniform, the dispersion between the particles is good, and there is a linear structure in the direction perpendicular to the surface of the Cu foil.

[0049] The negative electrode and the lithium ion b...

Embodiment 3

[0052] Preparation of CuO thin film: select 30 μm thick Cu foil as the current collector Cu foil, pickle the surface of the Cu foil with 1.0 mol / L acetic acid, and then clean it with deionized water; place the cleaned Cu foil in In a closed tube furnace, dry at room temperature for 2 h under the protection of nitrogen; the temperature of the closed tube furnace was raised to 350 °C at a rate of 15 °C / min, and then oxygen was introduced at a flow rate of 100 mL / min, kept for 0.5 h, and then lowered to room temperature Finally, a CuO thin film was obtained on the surface of the current collector Cu foil.

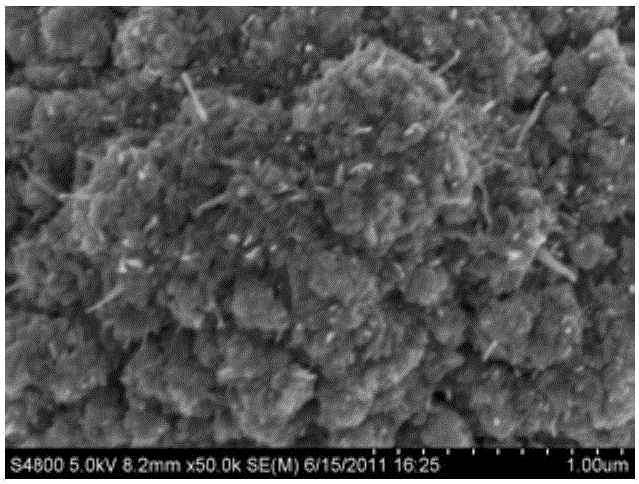

[0053] Morphology of CuO thin film: observe the morphology of the prepared CuO thin film by scanning electron microscope, the scanning electron microscope picture is shown in Figure 1c . It can be seen from the figure that the particle size is relatively uniform, the dispersion between them is very good, there are large gaps, and there is a thin rod-like structure in the dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com