Method for rapidly preparing carbon nanotube-two-dimensional titanium carbide composite material

A technology of two-dimensional titanium carbide and carbon nanotubes, which is applied in secondary batteries, electrochemical generators, hybrid capacitor electrodes, etc., can solve problems such as high cost, complicated process, restrictions on promotion and application, and achieve high production efficiency, The effect of simple operation and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

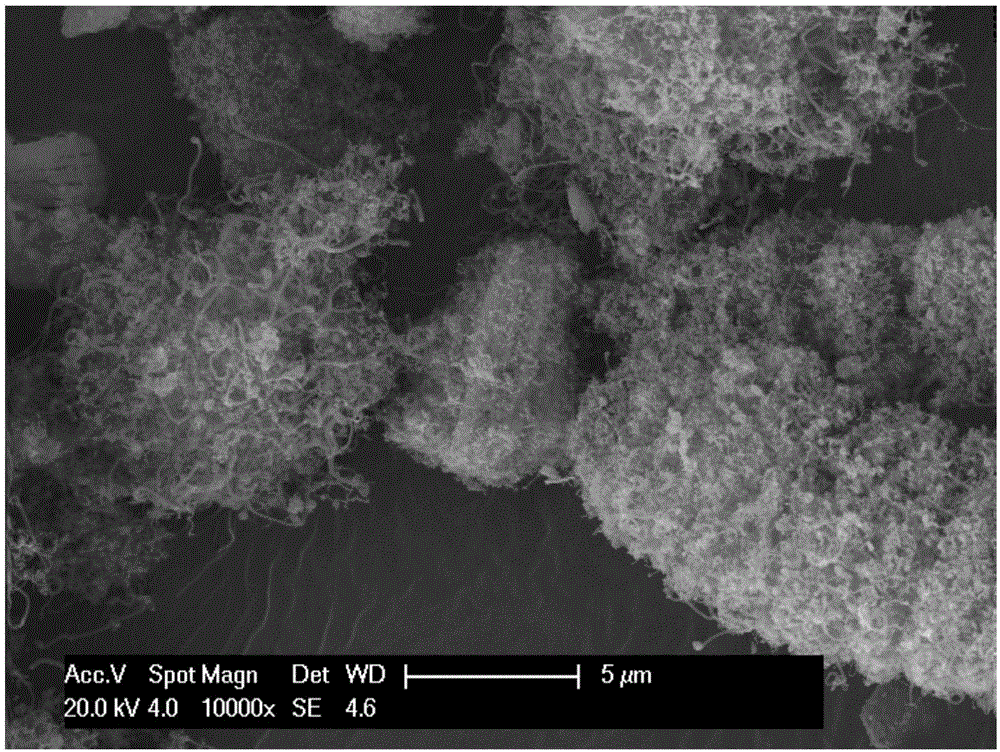

Image

Examples

Embodiment 1

[0024] Carbon nanotube-two-dimensional titanium carbide composite material prepared by dry mixing with a powder mixer and 900 watts of microwave heating:

[0025] 1. Mixing: put two-dimensional titanium carbide (100mg) and ferrocene (100mg) into a 10 ml plastic vial, and mix them on a powder mixer at a speed of 72 rpm for 1 hour;

[0026] 2. Microwave heating: Place the ceramic container containing the mixed powder in step 1 in a microwave device, and heat it rapidly with a power of 900 watts for 40 seconds, so as to obtain a black fluffy product, which is the target product.

Embodiment 2

[0028] Preparation of carbon nanotube-two-dimensional titanium carbide composites by manual grinding and dry mixing, and 720W microwave heating:

[0029] 1. Mixing: Accurately weigh 50 mg each of two-dimensional titanium carbide and ferrocene, put them into an agate mortar and grind carefully for 15 minutes;

[0030] 2. Microwave heating: place the quartz container containing the mixed powder in step 1 in a microwave device, and heat it rapidly at a power of 720 watts for 20 seconds to obtain a black fluffy product, which is the target product.

Embodiment 3

[0032] Preparation of carbon nanotube-two-dimensional titanium carbide composites by manual grinding and wet mixing, and 900W microwave heating:

[0033] 1. Mixing: Put 1mL of acetone solution into a ceramic container containing two-dimensional titanium carbide (100mg) and nickelocene (100mg), and stir by hand until the acetone is volatilized;

[0034] 2. Microwave heating: Place the ceramic container containing the mixed powder in step 1 in a microwave device, and heat it rapidly at a power of 900 watts for 40 seconds to obtain a black fluffy product with a weight of about 180 mg;

[0035] 3. Mix the powder in step 2 with an equal amount of nickelocene, and then repeat steps 1 and 2 to obtain a larger amount of black fluffy product than in step 2, with a weight of about 300 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com