Three-dimensional porous carbon-coated zinc selenide material for lithium ion battery anodes and preparation method of material

A three-dimensional porous, zinc selenide technology, applied in the fields of energy and materials, can solve the problems of high capacity, long life and excellent rate performance, etc., and achieve the effects of easy industrial production, low cost, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

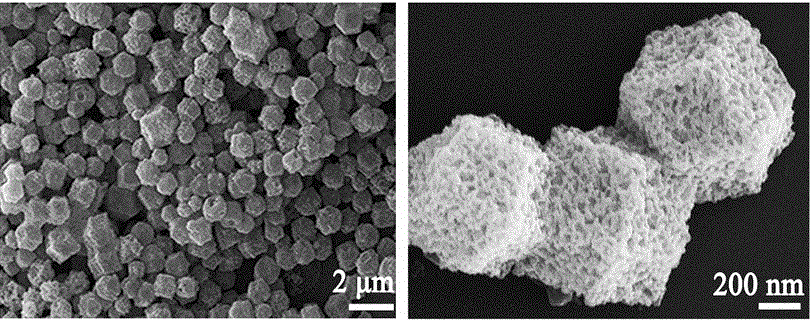

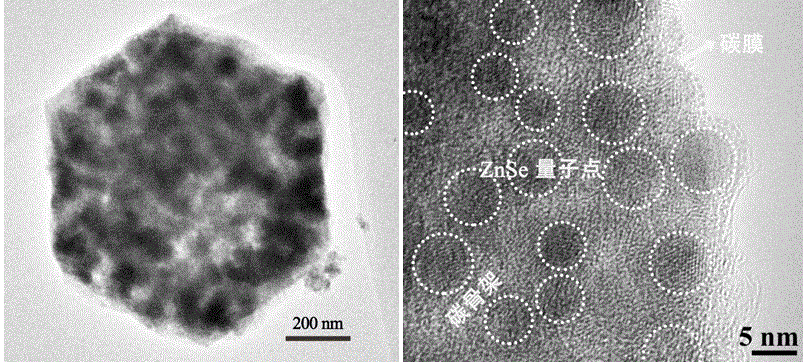

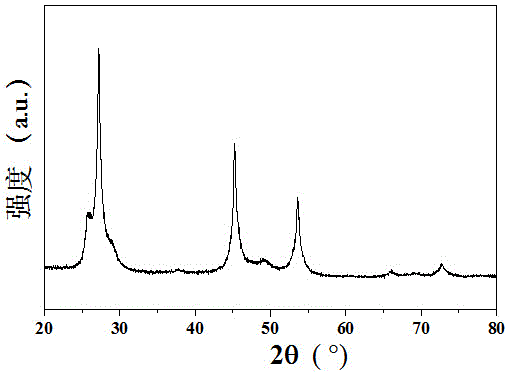

[0021] Embodiment 1: three-dimensional porous carbon-coated zinc selenide material and its preparation method and application, comprising the following steps:

[0022] (1) Preparation of ZIF-8 template with polyhedral morphology: Weigh 1.45 g of zinc nitrate hexahydrate and 1.66 g of 2-methylimidazole, dissolve them in 20 ml of methanol solution, stir and dissolve, and dissolve 2-methylimidazole Pour the imidazole solution into the zinc nitrate solution; stir for 5 minutes, let it stand at room temperature for 24 hours, centrifuge the product, wash it with ethanol solution for 4 times, and finally place it in a drying oven at 55 degrees Celsius. The obtained product is polyhedral ZIF -8; The product is white, mostly rhomboid dodecahedron, and the particle size is mainly distributed between 600 and 900 nanometers;

[0023] (2) Three-dimensional porous zinc selenide material and preparation: Weigh 200 mg of ZIF-8 and 200 mg of selenium powder and place them on both ends of the p...

Embodiment 2

[0026] Embodiment 2: three-dimensional porous carbon-coated zinc selenide material and its preparation method and application, comprising the following steps:

[0027] (1) Preparation of ZIF-8 template with polyhedral morphology: Weigh 1.45 g of zinc nitrate hexahydrate and 1.66 g of 2-methylimidazole, dissolve them in 20 ml of methanol solution, stir and dissolve, and dissolve 2-methylimidazole Pour the imidazole solution into the zinc nitrate solution; stir for 5 minutes, let it stand at room temperature for 24 hours, centrifuge the product, wash it with ethanol solution for 4 times, and finally place it in a drying oven at 55 degrees Celsius. The obtained product is polyhedral ZIF -8; The product is white, mostly rhomboid dodecahedron, and the particle size is mainly distributed between 600 and 900 nanometers;

[0028] (2) Three-dimensional porous zinc selenide material and preparation: Weigh 200 mg of ZIF-8 and 200 mg of selenium powder and place them on both ends of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com