High-performance bipolar plate with graphene-reinforced surface for fuel cell and preparation method of high-performance bipolar plate

A fuel cell and bipolar plate technology, applied in the direction of fuel cells, fuel cell components, circuits, etc., can solve the problems of reducing the output voltage of fuel cells, peeling off, peeling and caving of the gold layer of titanium bipolar plates, etc., so as to reduce the overall Contact resistance, chemical stability, the effect of improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

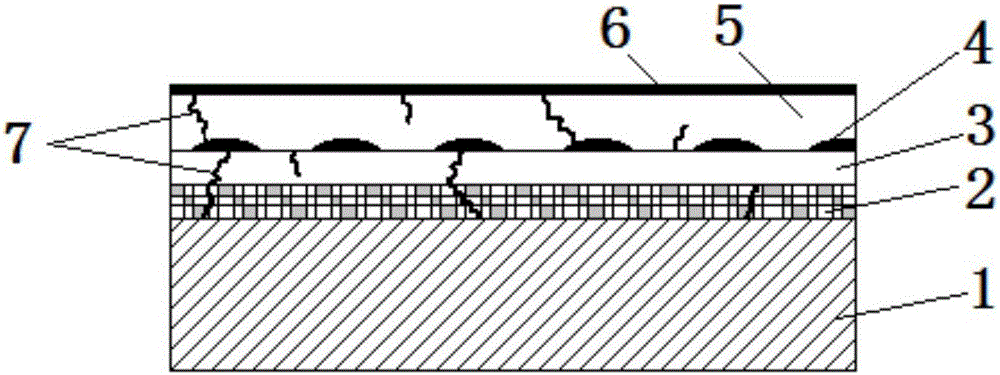

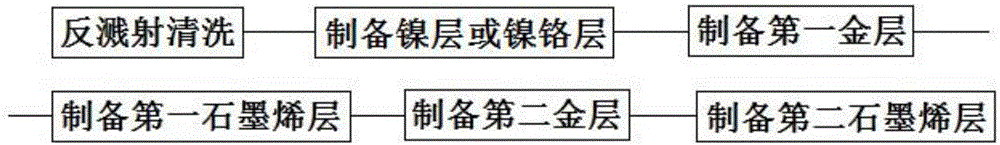

[0046] Embodiment 1, as attached figure 1 , 2 shown.

[0047] This embodiment is implemented according to the following steps under the following implementation conditions and technical requirements:

[0048] (1) Anti-sputter cleaning:

[0049] Put the titanium bipolar plate 1 substrate into the ultrasonic cleaning equipment for cleaning, and after drying in the vacuum drying furnace, put it on the material table in the vacuum chamber of the magnetron sputtering equipment, and pump the vacuum in the vacuum chamber to 2×10 -4 After Pa, a mixed gas of argon and hydrogen is introduced into the vacuum chamber, wherein the flow rate of argon gas is 80 SCCM, and the flow rate of hydrogen gas is 40 SCCM, so that the pressure of the vacuum chamber is maintained at 2 Pa. Before cleaning by reverse sputtering, a baffle plate is used to separate each target material from the titanium bipolar plate 1 substrate, so as to prevent titanium film from being deposited on the surface of each ...

Embodiment 2

[0061] Embodiment 2, as attached figure 1 , 2 shown.

[0062] This embodiment is implemented according to the following steps under the following implementation conditions and technical requirements:

[0063] (1) Anti-sputter cleaning:

[0064] Put the titanium bipolar plate 1 substrate into the ultrasonic cleaning equipment for cleaning, and after drying in the vacuum drying furnace, put it on the material table in the vacuum chamber of the magnetron sputtering equipment, and pump the vacuum in the vacuum chamber to 2×10 -4 After Pa, a mixed gas of argon and hydrogen is introduced into the vacuum chamber, wherein the flow rate of argon gas is 80 SCCM, and the flow rate of hydrogen gas is 40 SCCM, so that the pressure of the vacuum chamber is maintained at 2 Pa. Before cleaning by reverse sputtering, a baffle plate is used to separate each target material from the titanium bipolar plate 1 substrate, so as to prevent titanium film from being deposited on the surface of each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com