Flexible pulse sensor and manufacturing method thereof

A pulse sensor, flexible technology, applied in the direction of gaseous chemical plating, metal material coating process, catheter, etc., to achieve good mechanical stability, enhance mechanical stability, and increase the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

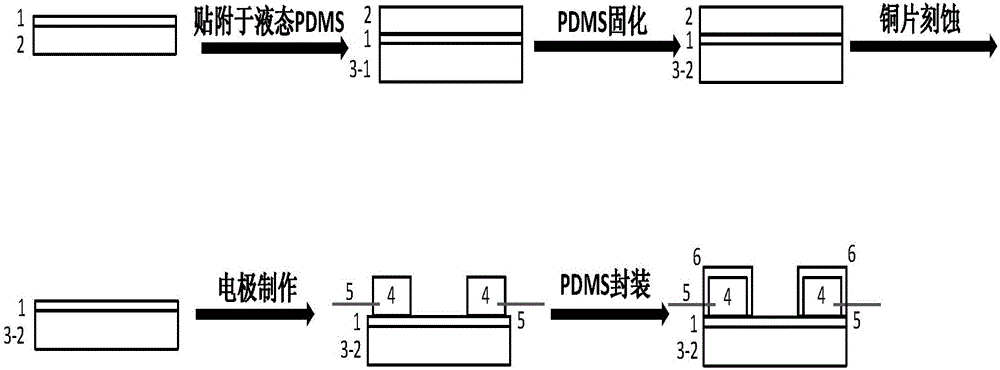

[0072] A kind of preparation method of the flexible pulse sensor based on carbon nanotube-graphene composite film, comprises the following steps (flow chart as image 3 shown):

[0073] (1) Mix the matrix of PDMS and the curing agent at a mass ratio of 5-15:1, and put it into a vacuum desiccator to vacuumize to remove air bubbles;

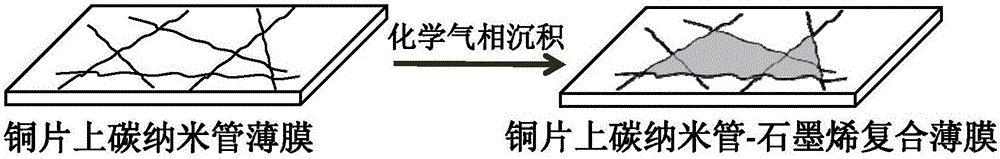

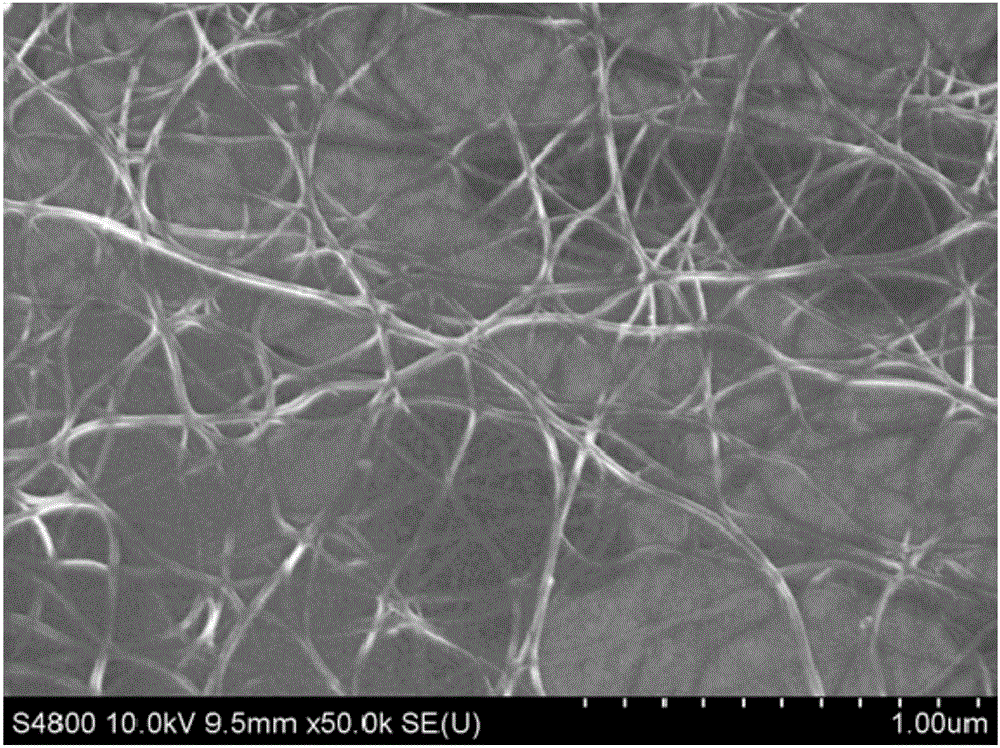

[0074] (2) Float the flat copper sheet with carbon nanotube-graphene composite film upside down (the film is facing down) on the liquid PDMS, wherein the carbon nanotube-graphene composite film is prepared as follows: chemical vapor phase The carbon nanotube film synthesized by the deposition method is transferred to the copper sheet, and then the graphene is grown in the pores of the carbon nanotube by chemical vapor deposition to obtain the carbon nanotube-graphene composite film on the copper sheet (refer to the patent disclosed in 201410128376.0 Preparation method preparation), the preparation schematic diagram of carbon nanotube-graphene comp...

Embodiment 1

[0080] A method for preparing a flexible pulse sensor based on carbon nanotube-graphene composite film, comprising the steps of:

[0081] (1) Transfer the carbon nanotube film with a light transmittance of 90% to the surface of the copper foil, place the copper foil in a tube furnace, and evacuate to 5.0×10 -2 Torr, the argon gas with a flow rate of 300 sccm and the hydrogen gas with a flow rate of 60 sccm are introduced, the temperature of the tube furnace is raised to 1000 ° C within 40 minutes, and the temperature is continued for 30 minutes, and then the methane with a flow rate of 20 sccm is fed in, and the reaction is continued for 30 minutes; the temperature is lowered to room temperature, Obtain a carbon nanotube-graphene composite film with a light transmittance of 86% on copper foil;

[0082] (2) The copper sheet for growing carbon nanotubes-graphene is buckled upside down to the surface of liquid PDMS where the PDMS precursor liquid and curing agent are mixed in a m...

Embodiment 2

[0087] A method for preparing a flexible pulse sensor based on carbon nanotube-graphene composite film, comprising the steps of:

[0088] (1) Transfer the carbon nanotube film with a transmittance of 85% to the surface of the copper foil, place the copper foil in a tube furnace, and evacuate to 4.2×10 -2 Torr, argon gas with a flow rate of 500 sccm and hydrogen gas with a flow rate of 80 sccm were introduced, and the temperature of the tube furnace was raised to 1050 ° C within 60 minutes, and the temperature was continued for 30 minutes, and then methane with a flow rate of 10 sccm was introduced, and the reaction was continued for 30 minutes. Cool down to room temperature to obtain a carbon nanotube-graphene composite film with a transmittance of 80% on the copper foil;

[0089] (2) Invert the copper sheet for growing carbon nanotubes-graphene onto the surface of liquid PDMS where the PDMS precursor liquid and curing agent are mixed in a mass ratio of 10:1 and the air bubble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com