Polypeptide sustained-release microsphere preparation and preparation method thereof

A slow-release microsphere preparation and polypeptide slow-release technology, which is applied in the field of medicine, can solve the problems of short half-life and poor patient compliance, and achieve the effects of good encapsulation rate, long drug release time and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

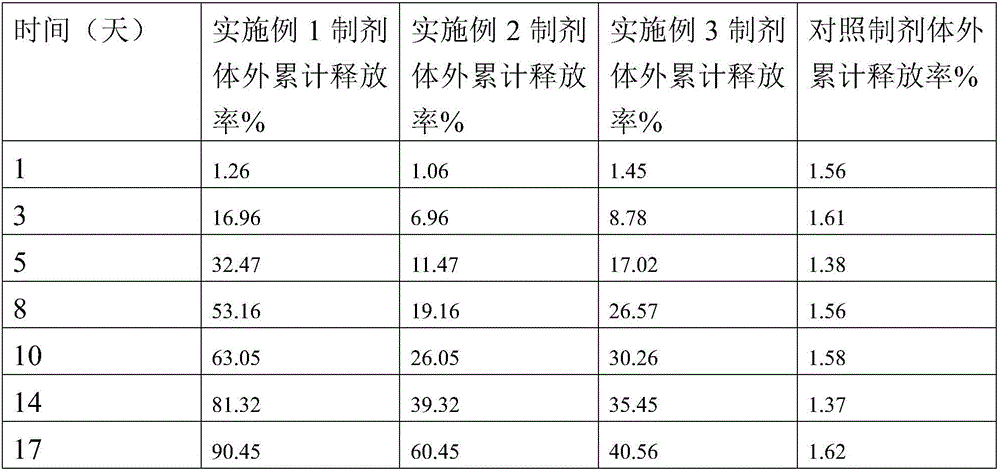

Embodiment 1

[0102] Embodiment 1 microsphere preparation and preparation method thereof

[0103] (1) Dissolve 5g of purified 50:50 DLG 2A PLGA (polymerization ratio 1:1, PLGA inherent viscosity around 1, PLGA with carboxyl group at the end group), 0.3g of exenatide in 50ml of glacial acetic acid, forming a solution of polymer and drug;

[0104] (2) Mix 200ml of n-heptane and 200ml of silicone oil to prepare coagulant; shear the solution of polymer and medicine prepared in step (1), and add the coagulant prepared at the same time to obtain initial microspheres;

[0105] (3) Transfer the initial microspheres prepared in step (3) to a mixed solution of 1800ml n-heptane and 1800ml ethanol, and stir at 20°C for 1-2h;

[0106] (4) with 200ml 50% n-heptane-ethanol solution flushing the residual solvent on the microsphere surface that step (3) obtains;

[0107] (5) Using a multilayer sieve to collect the microspheres obtained in step (4), rinse with 50% n-heptane-ethanol solution. Dry at 4°C fo...

Embodiment 2

[0108] Embodiment 2 microsphere preparation and preparation method thereof

[0109] (1) Dissolve 5g of purified 50:50 DLG 3A PLGA, 0.3g of exenatide in 50ml of glacial acetic acid to form a solution of polymer and drug;

[0110] (2) Mix 200ml of n-heptane and 200ml of silicone oil to prepare coagulant; shear the solution of polymer and medicine prepared in step (1), and add the coagulant prepared at the same time to obtain initial microspheres;

[0111] (3) the initial microspheres prepared by step (2) are transferred to the mixed solution of 1500ml n-heptane and 1500ml ethanol;

[0112] (4) with 200ml 50% n-heptane-ethanol solution flushing the residual solvent on the microsphere surface that step (3) obtains;

[0113] (5) Using a multilayer sieve to collect the microspheres obtained in step (4), rinse with 50% n-heptane-ethanol solution. Dry at 4°C for 24h, vacuum dry at 25°C for 24h, and vacuum dry at 35°C for 24h.

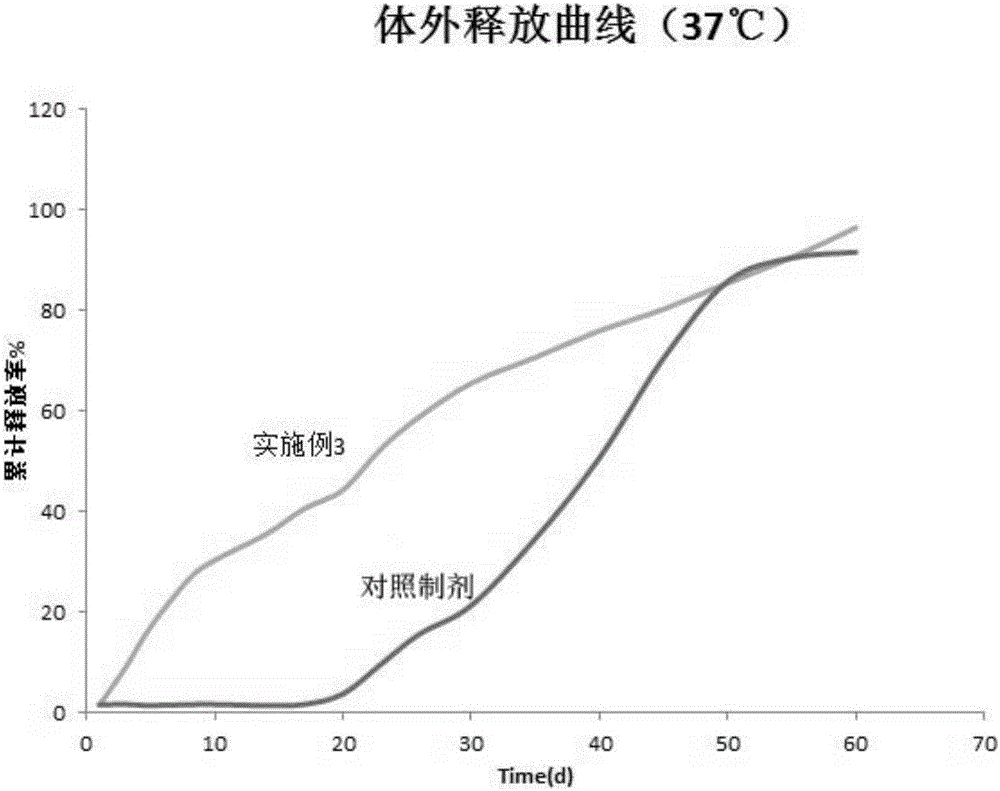

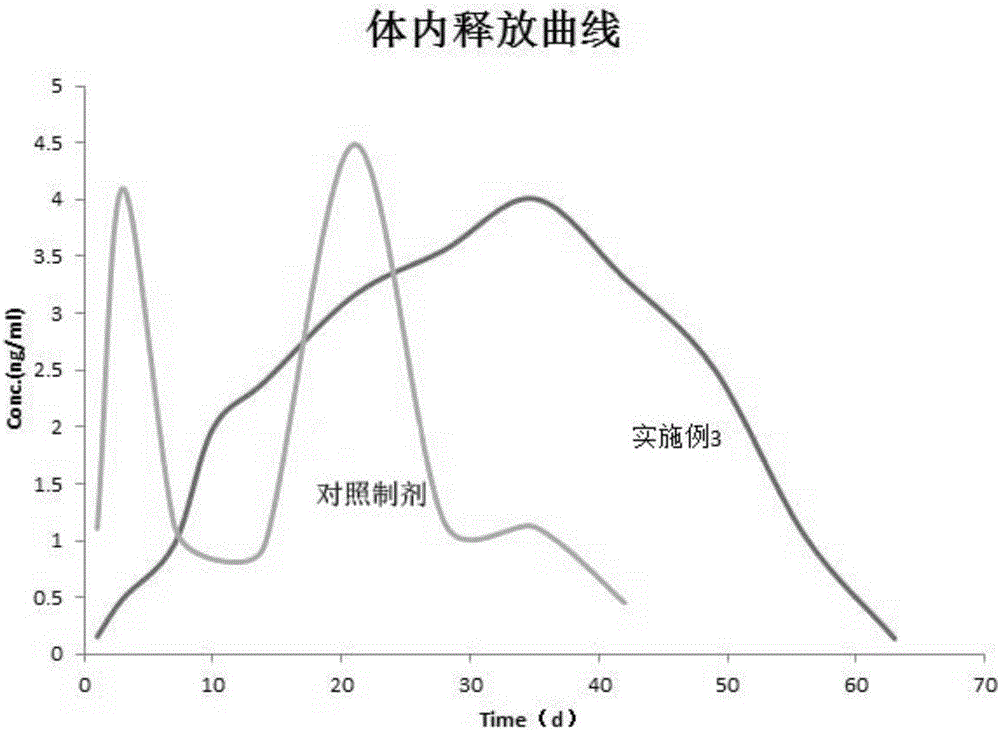

Embodiment 3

[0114] Embodiment 3 microsphere preparation and preparation method thereof

[0115] (1) Dissolve 5g of purified 100 2A PLA and 0.3g of exenatide in 50ml of glacial acetic acid to form a solution of polymer and drug;

[0116] (2) Mix 200ml of n-heptane and 200ml of silicone oil to prepare coagulant; shear the solution of polymer and medicine prepared in step (1), and add the coagulant prepared at the same time to obtain initial microspheres;

[0117] (3) Transfer the initial microspheres prepared in step (2) to a mixed solution of 2100ml n-heptane and 2100ml ethanol, and stir at 20°C for 1-2h;

[0118] (4) with 200ml 50% n-heptane-ethanol solution flushing step (3) microsphere surface residual solvent that obtains;

[0119] (5) Using a multilayer sieve to collect the microspheres obtained in step (4), rinse with 50% n-heptane-ethanol solution. Dry at 4°C for 24h, vacuum dry at 25°C for 24h, and vacuum dry at 35°C for 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com