Production method of graphene/ceramic composite filter membrane

A ceramic filter membrane and ceramic composite technology, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of low binding force between graphene oxide and ceramic filter membrane, low filtration efficiency, etc., and achieve improved filtration efficiency. Separation effect, high safety and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

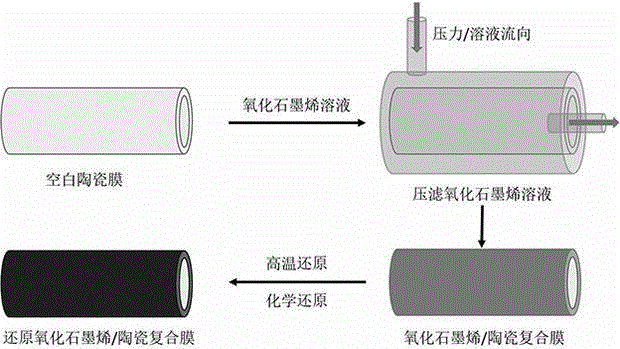

[0031] This embodiment provides a method for preparing a graphene / ceramic composite filter membrane, comprising the following steps: configuring a graphene oxide solution with a certain concentration;

[0032] The graphene oxide solution is infiltrated on the surface of the ceramic filter membrane and in the pores of the ceramic filter membrane;

[0033] Reducing the graphene oxide / ceramic filter membrane to obtain a graphene / ceramic composite filter membrane.

[0034] The preparation method of the above-mentioned graphene / ceramic composite filter membrane can infiltrate the graphene oxide solution into the micropores of the ceramic filter membrane, avoiding that in the prior art, the graphene oxide solution can only be adsorbed on the surface of the ceramic filter membrane; thus The pore size of the micropores in the ceramic membrane is reduced; the graphene oxide is reduced to graphene, so that the graphene and the ceramic filter membrane are chemically bonded together, and ...

Embodiment approach

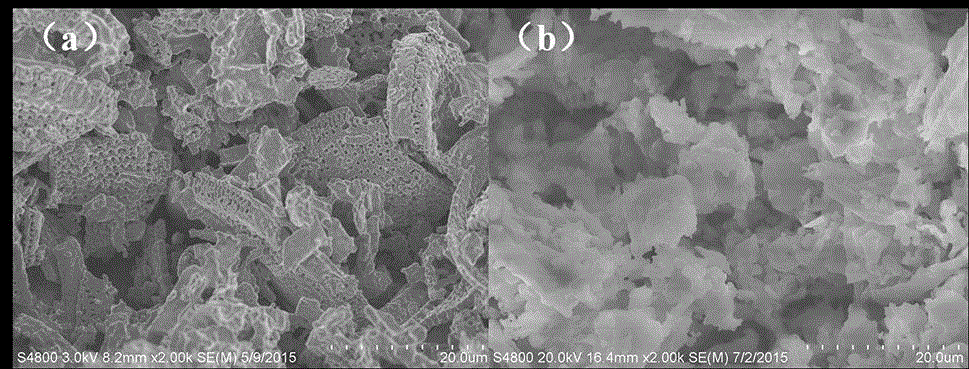

[0053] Choose distilled water as the solvent, disperse the freeze-dried and solidified graphene oxide in the aqueous solution, configure the graphene oxide solution with a concentration of 1mg / ml, and ultrasonicate the graphene oxide solution at a power of 600W for 0.5 hours, and fully pulverize and disperse it to form homogeneous graphene oxide solution.

[0054] The graphene oxide was filled into the pores of the zirconia ceramic membrane by the filter press method. Press filter from the inside of the ceramic membrane to the outside of the ceramic membrane for 30 minutes, then press filter from the outside of the ceramic membrane to the inside of the ceramic filter membrane for 30 minutes, dry naturally, repeat the above steps twice, and obtain a graphene oxide / ceramic composite filled many times filter membrane.

[0055] Place the above-mentioned ceramic filter membrane with graphene oxide fragments embedded in the tube furnace, first exhaust the air in the quartz tube in ...

specific Embodiment approach

[0060] The difference from Example 1 is that the ceramic filter membrane filled with graphene oxide is placed in a sodium borohydride acid solution, reduced for 5 hours, and dried to obtain a graphene / ceramic composite filter membrane. The retention rate of bovine serum albumin by the graphene / zirconia ceramic composite membrane after reduction in this embodiment is 51.6%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com