Preparation method and application of carbon dot/mesoporous silica composite material

A technology of mesoporous silica and composite materials, which is applied in the direction of chemical instruments and methods, luminescent materials, alkali metal compounds, etc., can solve the problems of complex and cumbersome preparation methods, and achieve separation and enrichment, good pore structure, and adsorption good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

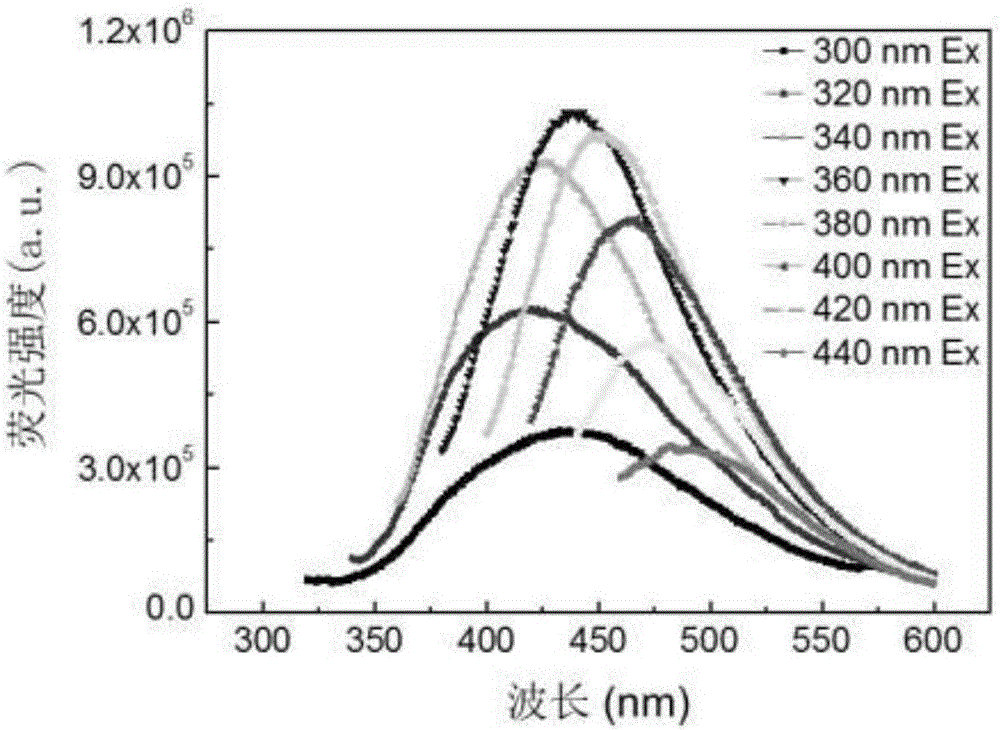

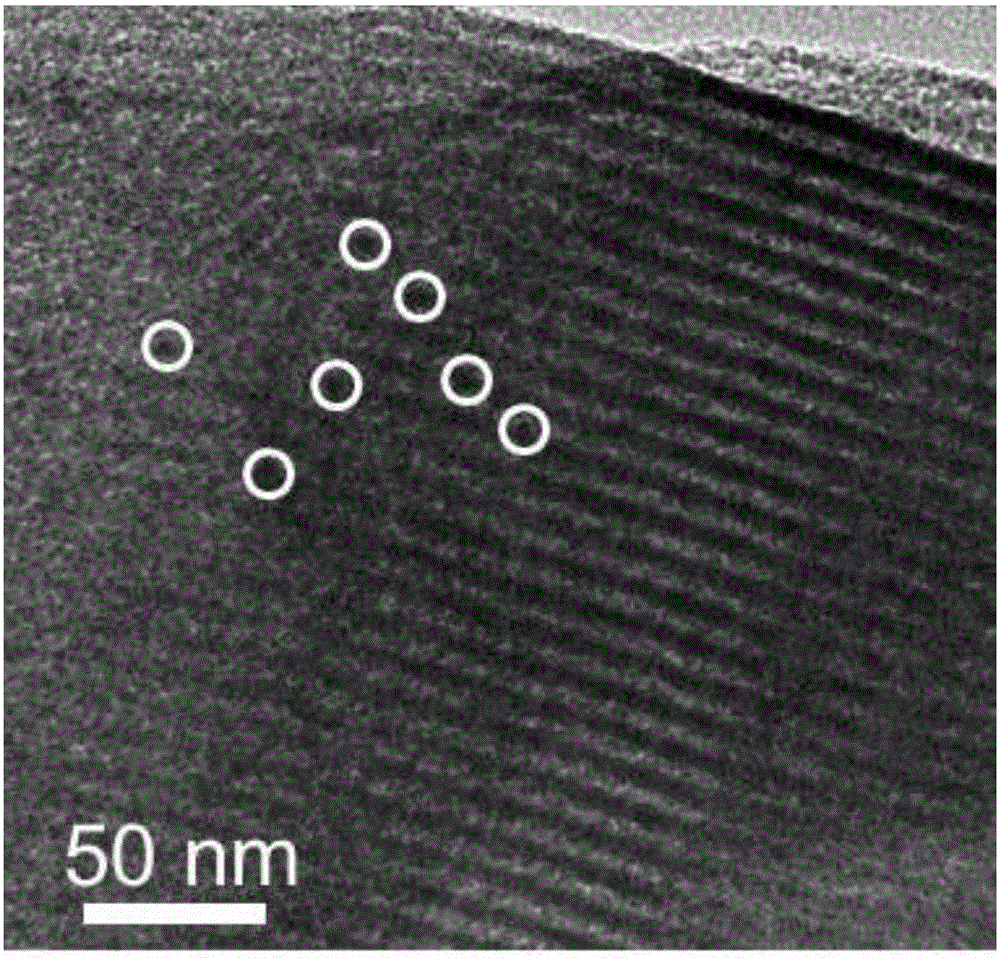

Embodiment 1

[0024] Preparation of a carbon dot / mesoporous silica composite material: Rinse a 25mL beaker with deionized water, dry it for later use, weigh 0.960g of citric acid into the beaker, measure 500μL of ethylenediamine and pour it into beaker, and add 10mL deionized water, 30mg mesoporous silica and 50mg sodium nitrate into it, and ultrasonically disperse to obtain a white suspension; pour the solution into an H-type reaction vessel, place the reactor on the test bench, Adjust the argon gas flow to 60mL / min, the two discharge electrodes are directly above the H-type reactor, the cathode is a platinum wire electrode, the anode is an argon tube with an inner diameter of 180μm, and the output current of the constant current power supply is adjusted to 10mA, and the voltage is 2900V. After the experiment started, the cathode platinum wire electrode was immersed in the solution, and the anode argon gas tube was slowly lowered until the discharge started. At this time, a stopwatch was us...

Embodiment 2

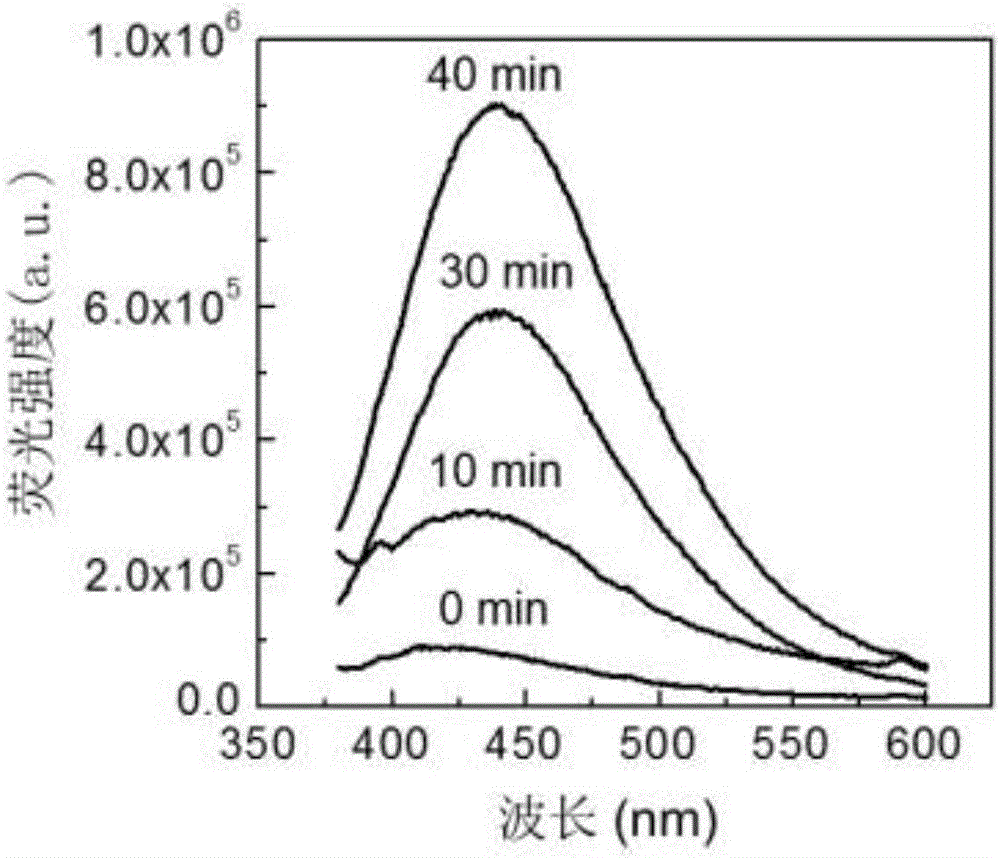

[0027] Keep discharging stably and continue 20min, other conditions are identical with embodiment 1, the fluorescence spectrum of prepared carbon dot / mesoporous silica composite material is as follows image 3 It is shown that the composite material has good fluorescence properties.

Embodiment 3

[0029] Keep the discharge stable and continue for 30min, other conditions are the same as in Example 1, the fluorescence spectrum of the prepared carbon dot / mesoporous silica composite material is as follows image 3 It is shown that the composite material has good fluorescence properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com