Chemical type hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of large crystallinity damage, low pore volume of modified Y molecular sieve, and affecting performance, etc. Achieve the effects of reducing the degree of skeleton damage, high selectivity of heavy naphtha, and good quality of tail oil products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

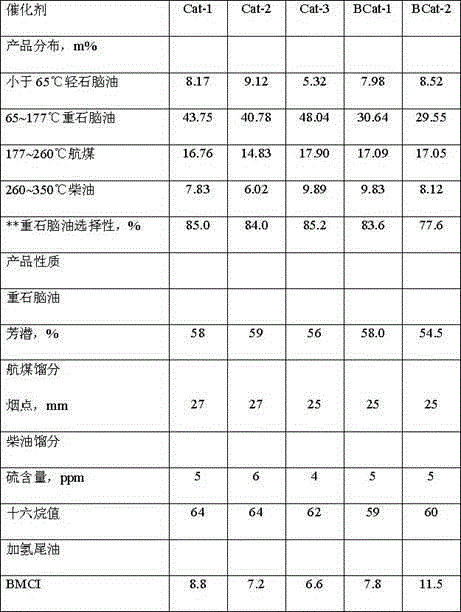

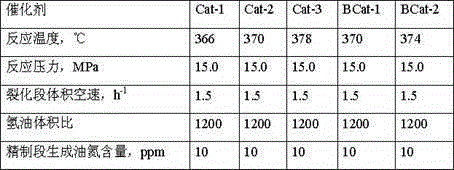

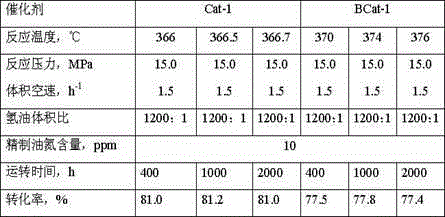

Examples

Embodiment 1

[0025](1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 2.0mol / L according to the liquid-solid ratio of 4:1, exchange at 80°C for 2 hours, repeat this process twice, and the exchanged Y molecular sieve Na content in Na 2 O is calculated as 1.8%;

[0026] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 550°C and 0.3Mpa for 2 hours;

[0027] (3) Mix the Y molecular sieve obtained in step (2) with a sodium chloride solution with a concentration of 1.7mol / L according to the liquid-solid ratio of 5:1, exchange at 65°C for 1 hour, repeat this process 3 times, and the Y molecular sieve after exchange Na content in Na 2 O is calculated as 3.8%;

[0028] (4) The molecular sieve obtained in step (3) is mixed with 0.5mol / L ammonium fluorosilicate and 0.3mol / L citric acid (with H + ) solution mixed beating, 85 ℃ for 2 hours;

[0029] (5) The Y molecular sieve treated in step (4) was ...

Embodiment 2

[0035] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium chloride with a concentration of 2.5mol / L according to the liquid-solid ratio of 5:1, exchange at 85°C for 2 hours, repeat this process twice, and the exchanged Y Na content in molecular sieve is Na 2 O is calculated as 1.3%;

[0036] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 530°C and 0.15Mpa for 1.5 hours;

[0037] (3) Mix the Y molecular sieve obtained in step (2) with sodium nitrate with a concentration of 1.5mol / L according to the liquid-solid ratio of 5:1, exchange at 80°C for 1 hour, repeat this process twice, and the Na in the exchanged Y molecular sieve The content is 3.6% in terms of Na2O;

[0038] (4) The molecular sieve obtained in step (3) is mixed with ammonium fluorosilicate solution with a concentration of 0.5 mol / L according to the liquid-solid ratio of 5:1 and beaten, and treated at 95°C for 2 hours;

[0039] (5) The Y molecu...

Embodiment 3

[0045] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 1.6mol / L according to the liquid-solid ratio of 3:1, exchange at 80°C for 2 hours, repeat this process twice, and the exchanged Y molecular sieve Na content in Na 2 O is calculated as 2.0%;

[0046] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 550°C and 0.2Mpa for 2 hours;

[0047] (3) Mix the Y molecular sieve obtained in step (2) with a mixed solution containing sodium nitrate and glycerol of 3.0 mol / L and 0.2 mol / L respectively at a liquid-solid ratio of 5:1, exchange at 80°C for 1 hour, repeat This process is performed twice, and the Na content in the Y molecular sieve after exchange is represented by Na 2 O is calculated as 5.3%;

[0048] (4) The molecular sieve obtained in step (3) is mixed with ammonium fluorosilicate solution with a concentration of 0.7mol / L according to the liquid-solid ratio of 10:1 and b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com