A hydrocracking catalyst grading method and catalytic diesel hydroconversion process

A hydrocracking and catalyst technology, which is used in catalyst regeneration/reactivation, physical/chemical process catalysts, molecular sieve catalysts, etc., to improve the selectivity of hydrogenation and cracking reactions, improve cetane number, and ensure the quality of diesel products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

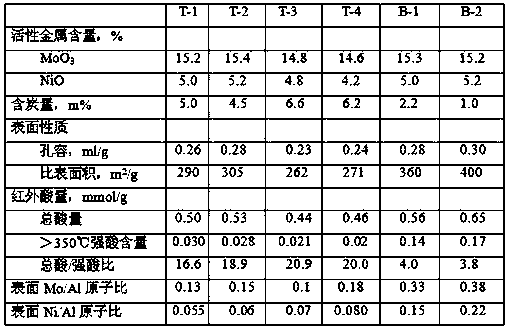

Embodiment 1

[0041] (1) Take the hydrocracking standby agent 1 after the operation of an industrial catalytic diesel hydroconversion unit and place it in the regeneration furnace;

[0042] (2) Introduce an oxygen / nitrogen mixed gas with an oxygen content of 1v% into the regeneration furnace, control the gas / agent ratio to 4000, and at the same time, raise the temperature to 380°C at a heating rate of 25°C / h, and obtain Example 1 after 4 hours of constant temperature roasting Regenerant, number T-1;

Embodiment 2

[0044] (1) Take the hydrocracking standby agent 2 after the operation of an industrial catalytic diesel hydroconversion unit and place it in the regeneration furnace;

[0045] (2) Introduce an oxygen / nitrogen mixed gas with an oxygen content of 3v% into the regenerating furnace, control the gas / agent ratio to 1500, at the same time, raise the temperature to 350°C at a heating rate of 25°C / h, and obtain Example 2 after constant temperature roasting for 10 hours Regenerant, No. T-2

Embodiment 3

[0047] (1) Take the hydrocracking standby agent 3 after the operation of an industrial catalytic diesel hydroconversion unit and place it in the regeneration furnace;

[0048] (2) Introduce oxygen / CO with an oxygen content of 3v% into the regeneration furnace 2 Gas mixed gas, the gas / agent ratio is controlled to 1500, at the same time, the temperature is raised to 300°C at a heating rate of 25°C / h, and the regenerant of Example 3 is obtained after constant temperature roasting for 15 hours, numbered T-3;

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com