Sorting method of oxidized coal slurry

A technology for coal oxidation and separation, applied in flotation, solid separation and other directions, can solve the problems of low recovery rate of flotation, large consumption of oxidized coal, etc., and achieve the effects of significant economic benefits, low operating costs, and poor selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

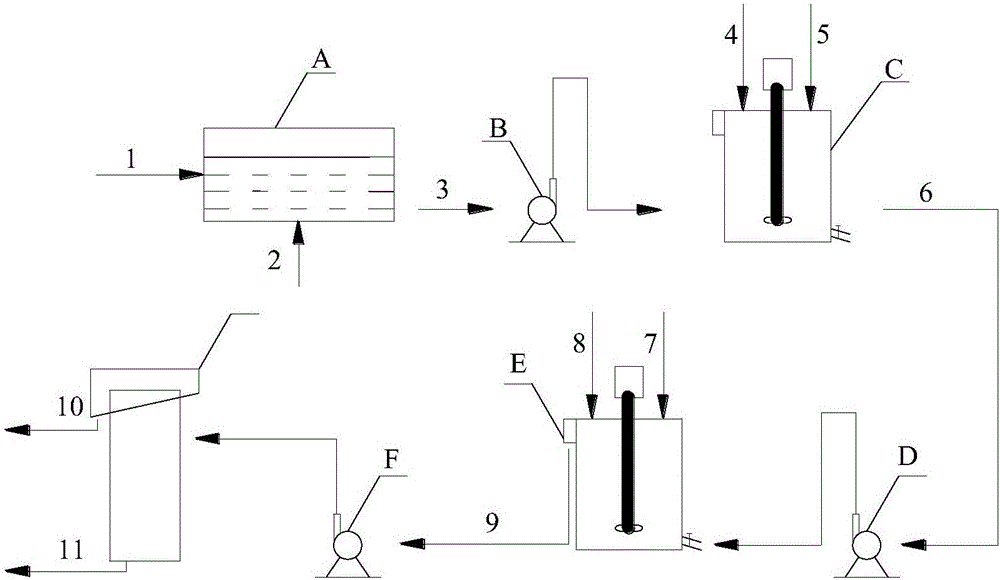

[0031] Such as figure 1 , a method for sorting oxidized coal slime based on CO2 bubbles, comprising the following steps:

[0032] Pass CO2 gas into water tank A and mix with water 1 to prepare CO2 saturated aqueous solution. Feed the prepared CO2 saturated aqueous solution into the mixing tank C through the pump B, adjust the pH value of the aqueous solution to 7 by adding NaOH4 to the saturated CO2 aqueous solution, mix the oxidized coal 5 and the CO2 aqueous solution, and pass the fully mixed pulp 6 through the pump D Feed into the mixing tank E, and add the flotation agent 7 and the foaming agent 8, the flotation pulp 9 is obtained after the pulp pretreatment, and the flotation pulp 9 is fed into the flotation column F through the pump, and the clean coal 10 is obtained by flotation and tailings11.

[0033] The ratio of CO2 saturated solution, oxidized coal slime, foaming agent and flotation agent is to add 69g of oxidized coal slime, 0.002g of foaming agent and 0.03g of ...

Embodiment 2

[0037] Such as figure 1 , a method for sorting oxidized coal slime based on CO2 bubbles, comprising the following steps:

[0038] Pass CO2 gas into water tank A and mix with water 1 to prepare CO2 saturated aqueous solution. Feed the prepared CO2 saturated aqueous solution into the mixing tank C through the pump B, adjust the pH value of the aqueous solution to 7 by adding NaOH4 to the saturated CO2 aqueous solution, mix the oxidized coal 5 and the CO2 aqueous solution, and pass the fully mixed pulp 6 through the pump D Feed into the mixing tank E, and add the flotation agent 7 and the foaming agent 8, the flotation pulp 9 is obtained after the pulp pretreatment, and the flotation pulp 9 is fed into the flotation column F through the pump, and the clean coal 10 is obtained by flotation and tailings11.

[0039] The ratio of CO2 saturated solution, oxidized coal slime, foaming agent and flotation agent is to add 83g of oxidized coal slime, 0.004g of foaming agent and 0.035g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com