Municipal sludge blending modifying agent and sludge semi-drying method

A municipal sludge and modifier technology, which is applied in the field of municipal sludge semi-drying, municipal sludge mixing modifier, and municipal sludge treatment products, can solve the problem of not effectively reducing the quality of treated sludge and sludge Actual use of problems such as reduced disposal efficiency, increased sludge disposal volume and disposal cost to achieve the effects of improved chemical stability, easy promotion, and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A municipal sludge mixing modifier is prepared.

[0028] 1. Raw materials

[0029] Hydrogen peroxide: concentration 30%, industrial grade

[0030] Bamboo vinegar stock solution: commercially available

[0031] Lactic acid bacteria fermentation stock solution: commercially available

[0032] Complex aluminum: commercially available, industrial grade, add water to prepare a complex aluminum solution with a mass concentration of 30%.

[0033] 2. Preparation

[0034] 2.1 Preparation of component A (bamboo vinegar lactic acid mixture)

[0035] Take the bamboo vinegar stock solution and the lactic acid bacteria fermentation stock solution, and mix them evenly according to the ratio in Table 1.1. The obtained bamboo vinegar lactic acid mixture is packaged independently, and is respectively component A1, component A2 and component A3.

[0036] Table 1.1 Ratio of bamboo vinegar lactic acid mixture (unit: volume percentage)

[0037] number 1 number 2 number ...

Embodiment 2

[0044] Example 1 The use of the obtained municipal sludge mixing and modifying agent and the semi-drying of the sludge.

[0045] 1. Raw materials and equipment

[0046] Municipal sludge mixing modifier: prepared in Example 1

[0047] Municipal sludge: sludge from a sewage treatment plant in a certain city, with a moisture content of 90% to 97%

[0048] CaO: commercially available, industrial grade

[0049] Diaphragm filter press: commercially available "Jingjin" brand automatic high-pressure diaphragm filter press XMAZGF20 / 800-U.

[0050] 2. Mixing and upgrading operation of municipal sludge

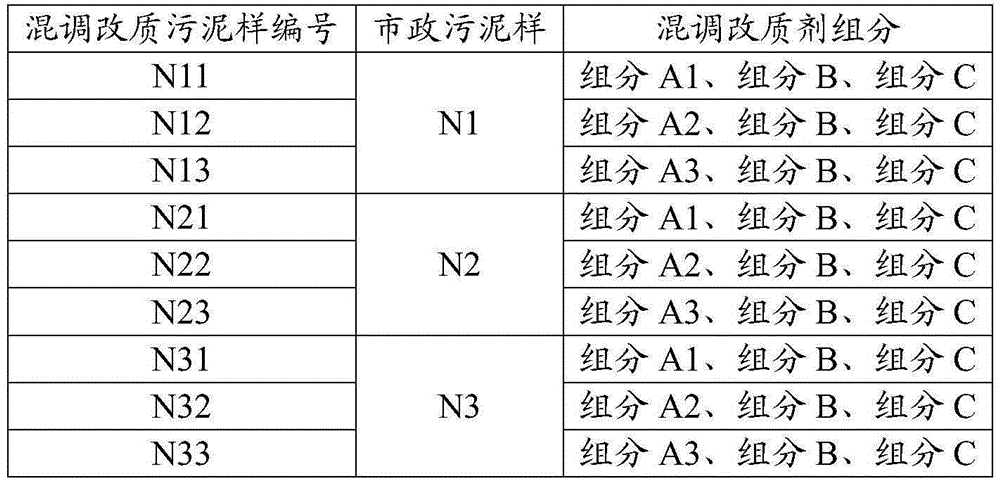

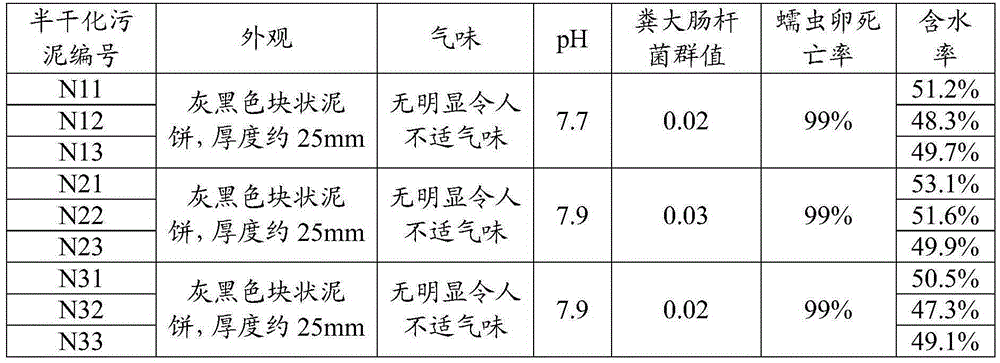

[0051] Take 3 municipal sludge samples N1, N2, N3 each 5m 3 150L each of component A1 or component A2 or component A3 was added to the sludge sample, and stirred evenly for 15 minutes; 25L of component B was added respectively, and stirred evenly for 15 minutes; CaO was added to adjust the sludge to pH = 7-9; Add component C5L, stir evenly for 15 minutes, and let stand for 60 minute...

Embodiment 3

[0062] The use of the municipal sludge mixing and modifying agent obtained in Example 1, which is the same as that of Example 2, will not be repeated, and the difference lies in the amount of the municipal sludge mixing and modifying agent.

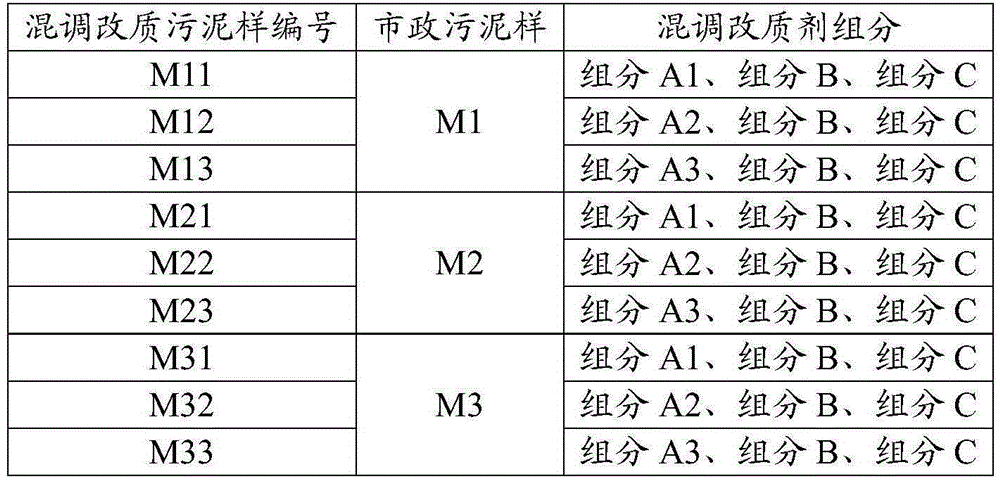

[0063] Municipal sludge mixing and upgrading operation: take 3 municipal sludge samples M1, M2, M3 each 5m 3 , add 25L each of component A1 or component A2 or component A3 to the sludge sample, and stir evenly for 15min; add 50L of component B, and stir evenly for 15min; add CaO to adjust the sludge to pH=9~11; add component C 25L, stir evenly for 15min, and let stand for 60min. After the supernatant and the flocculation sludge are clearly separated, the supernatant is removed, and the remaining sludge in the flocculation layer is the output sludge after the completion of 9 parts of mixing and upgrading respectively.

[0064] Table 3.1 Sludge samples for mixing and upgrading treatment

[0065]

[0066] Sludge filter press operation: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com