Functional ceramic for treating water special for cosmetics

A functional ceramic and water treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, filtration treatment, etc., can solve the problem of interference of tourmaline infrared radiation and bactericidal water performance, can not effectively improve water body metabolism, material Insufficient mixing and other problems to achieve the effect of maintaining skin microcirculation, good antibacterial and bactericidal effects, and maintaining luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

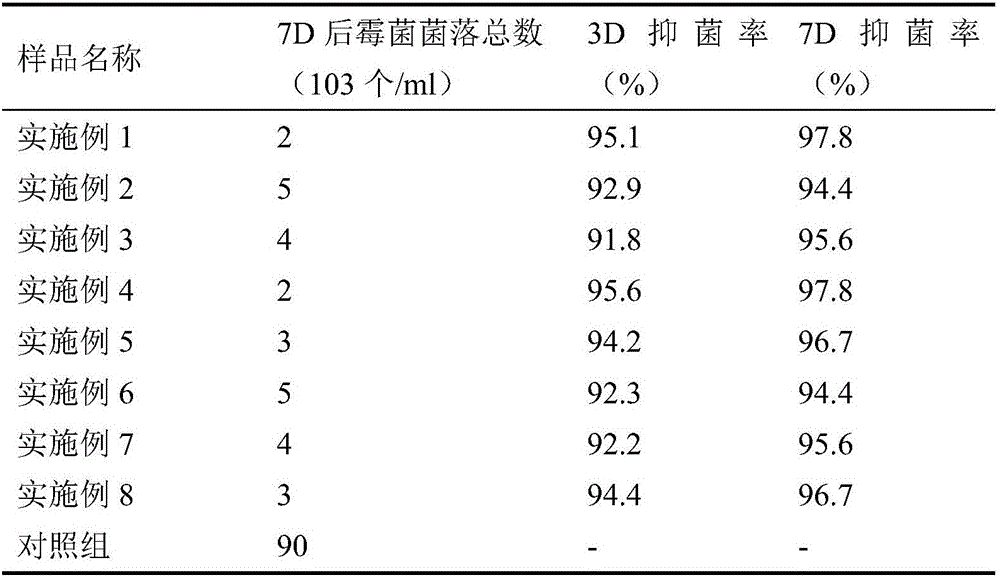

Examples

preparation example Construction

[0025] The steps of the preparation method of the above-mentioned special water treatment functional ceramics for cosmetics are:

[0026] 1) Refining tourmaline and iron tailings raw materials, the average particle size after refinement is not greater than 8μm:

[0027] Process tourmaline and iron tailings raw materials to an average particle size of D 50 = 20 μm, and then carry out secondary wet ball milling respectively, the samples after ball milling are centrifuged, the supernatant is taken, and dried to obtain the refined powder for later use; when performing secondary wet ball milling, select Distilled water is used as a dispersant, material: water: ball = 1:1.5:3 (the materials referred to here are the ceramic green body raw materials such as tourmaline, iron tailings, boric acid, clay; water is deionized water; the ball is matched with the ball mill Zirconia ceramic balls with a diameter of 3mm), the rotating speed is 200rad / min, and the ball milling time is 2h; when ...

Embodiment 1

[0035] The special water treatment functional ceramics for cosmetics in this embodiment, the raw materials of the functional ceramics are composed by weight percentage: 55% tourmaline; 5% clay; 35% boric acid; 5% iron tailings. The clay in this example is kaolin.

[0036] The preparation method is:

[0037] 1) The raw materials of tourmaline and iron tailings are refined, and the average particle size after refinement is 5.5 μm:

[0038] Process tourmaline and iron tailings raw materials to an average particle size of D 50 = 20 μm, and then carry out secondary wet ball milling respectively, the dispersant is distilled water, wherein the material: water: ball = 1:1.5:3, the speed is: 200rad / min, the ball milling time: 2h; the sample after ball milling is centrifuged Processing, wherein the centrifugal speed is: 1500rad / min, time: 5min; take the supernatant and dry it in a drying oven at 100°C for 10h to obtain mineral powder for later use;

[0039] 2) Weigh the refined tourm...

Embodiment 2

[0042] The types of raw materials and weight percentage composition and preparation method of the special water treatment functional ceramics for cosmetics in this embodiment are the same as those in Embodiment 1. The difference is that in the preparation process, a hydraulic press is used to make the mixed raw materials into a plate-shaped ceramic body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com