Ketone-hydrazine crosslinking aqueous acrylic resin with film-forming-assisting function and preparation method and application thereof

A technology of water-based acrylic and acrylic resin, applied in the direction of coating, etc., can solve the problems of high VOC content of the coating film, poor water resistance of the coating film, and large amount of addition, so as to reduce VOC content, reduce the amount of addition, and improve chemical resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

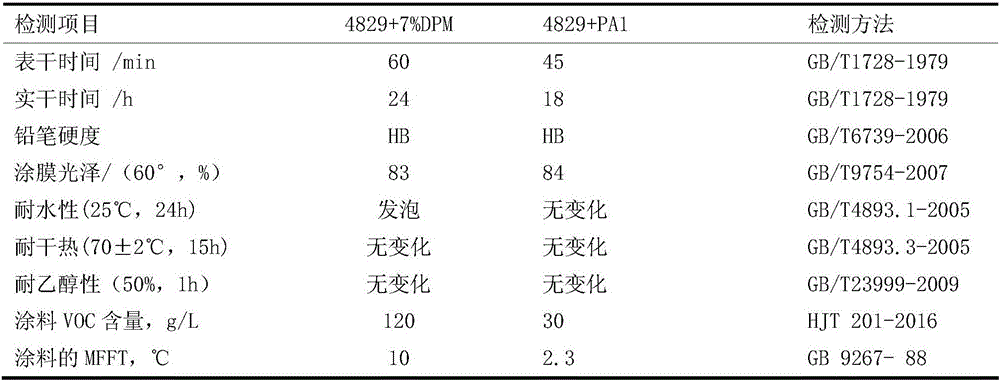

Examples

Embodiment 1

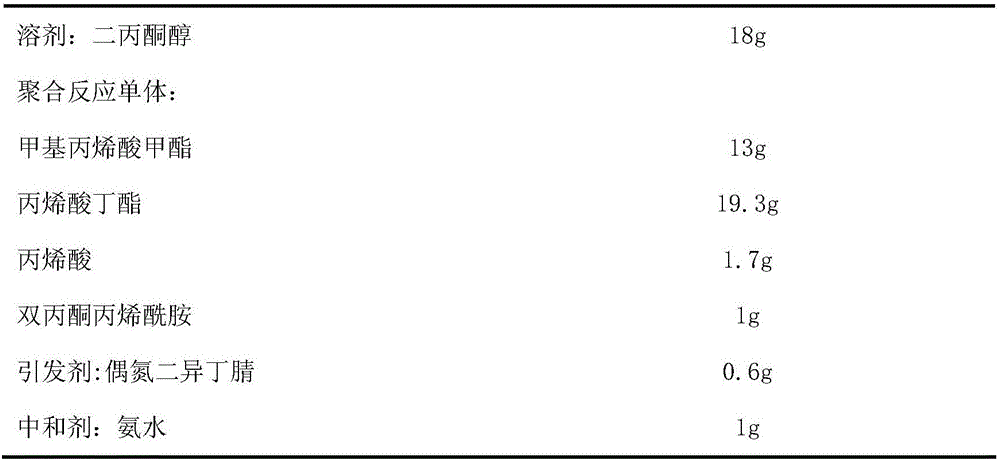

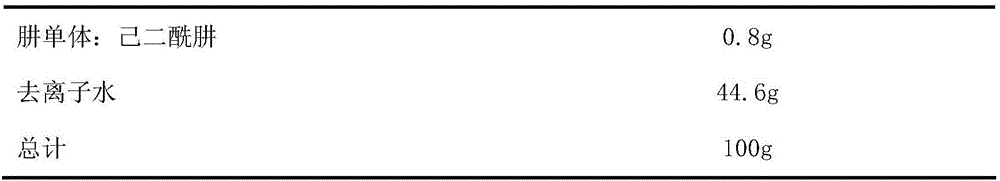

[0033] A kind of ketohydrazine cross-linked water-based acrylic resin with film-forming function, the raw material formulation components are as shown in Table 1:

[0034] Table 1

[0035]

[0036]

[0037] (1) The preparation technology of the ketone hydrazine crosslinking type water-based acrylic resin with film-forming function, comprises the following steps:

[0038] Dissolve the acrylic monomer, diacetone acrylamide and initiator azobisisobutyronitrile in the solvent to obtain a mixture, add 50% of the mass of the mixture into the reaction kettle, raise the temperature to 78°C, keep the temperature for 10min, and then put the remaining mixture Add it dropwise to the reaction kettle within 4 hours, and keep it warm for 2 hours after the drop is completed. Cool down to 60°C, add a neutralizing agent to react for 10 minutes; add deionized water to disperse, and after the dispersion is stable, distill under reduced pressure to remove the solvent, add adipic hydrazide and...

Embodiment 2

[0045] A kind of ketohydrazine cross-linked water-based acrylic resin with film-forming function, the raw material formula components are as shown in Table 2:

[0046] table 3

[0047]

[0048] (1) The preparation technology of the ketone hydrazine crosslinking type water-based acrylic resin with film-forming function, comprising the following steps: acrylic acid monomer, diacetone acrylamide and initiator azobisisobutyronitrile are dissolved in a solvent to obtain a mixture, Add 30% of the mass of the mixture into the reaction kettle, raise the temperature to 80° C. and keep it warm for 30 minutes; add the remaining mixture into the reaction kettle dropwise within 4 hours, and keep it warm for 2.5 hours after the dropping. Cool down to 50°C, add neutralizing agent to neutralize to pH 8‐10 and react for 30 minutes; add deionized water to disperse, and after the dispersion is stable, distill under reduced pressure to remove the solvent, add adipic hydrazide and stir evenly t...

Embodiment 3

[0055] A kind of ketone hydrazine cross-linked water-based acrylic resin with film-forming function, the raw material formula components are as shown in table 5:

[0056] table 5

[0057]

[0058] (1) The preparation technology of the ketone hydrazine cross-linking type waterborne acrylic resin with film-forming function, comprises the following steps: acrylic acid monomer, diacetone acrylamide and initiator azobisisobutyronitrile are dissolved in, to obtain mixture, and 20% of the mass of the mixture was added to the reactor, and the temperature was raised to 80° C. for 20 minutes; the remaining mixture was added dropwise to the reactor within 3 hours, and then kept for 2 hours for reaction. Cool down to 60°C, add neutralizing agent to neutralize to pH 8‐10 and react for 20 minutes; add deionized water to disperse, and after the dispersion is stable, distill under reduced pressure to remove the solvent, add adipic hydrazide and stir evenly to obtain a Ketohydrazine cross-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com