Storable waste and old rubber powder modified asphalt for alpine regions and preparation method thereof

A technology of waste rubber powder and modified asphalt, applied in the field of materials, can solve the problems of slow application progress of waste tire rubber powder rubber asphalt, poor thermal storage stability, construction limitations, etc. / Low temperature performance, the effect of improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

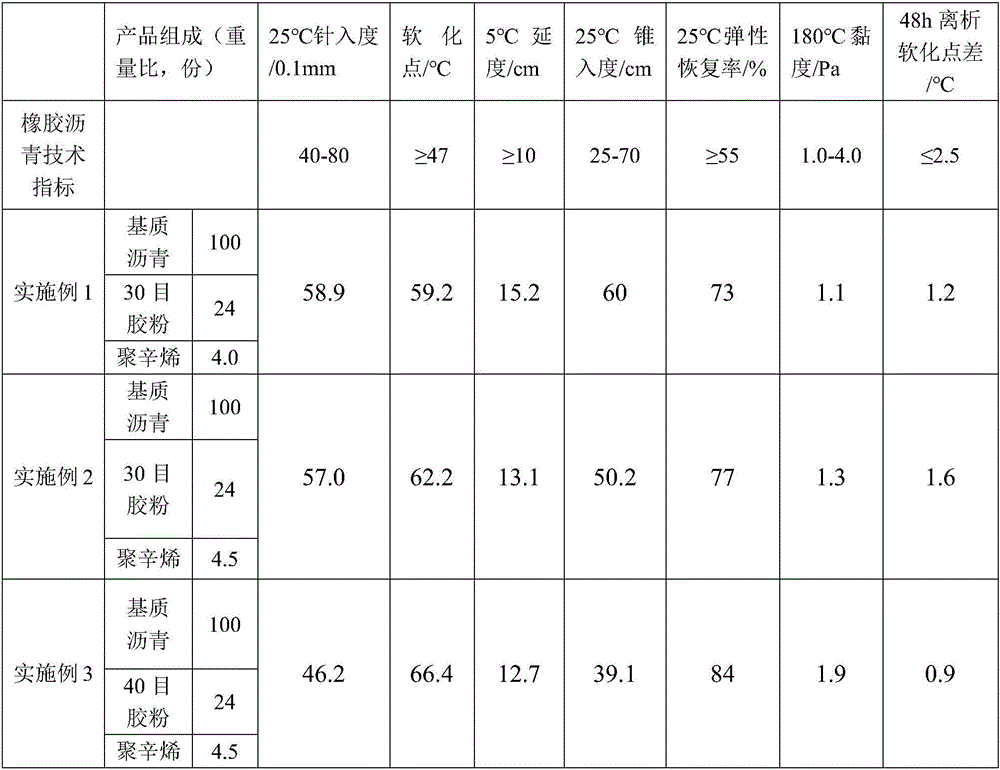

Embodiment 1

[0022] A kind of used tire rubber powder modified asphalt provided in this embodiment, the raw materials include by weight parts: 100 parts of SK-90# base asphalt produced in Korea, 24 parts of 30 mesh waste tire rubber powder, polyoctene rubber vita joint 4 doses.

[0023] The waste tire rubber powder is the waste radial tire ground and pulverized by normal temperature process, the relative density is 1.15, the metal content is 0.02%, the fiber content is 0.08%, the ash content is 5%, and the carbon black content is 31%.

[0024] Polyoctene rubber Vita linking agent, commercially available " 8012" identifies trans-polyoctene.

[0025] The preparation method of rubber powder modified asphalt in the present embodiment comprises the following steps:

[0026] 1) Mix the weighed and dried 30-mesh rubber powder and polyoctene evenly for later use;

[0027] 2) Set the oven temperature to 140°C, put SK-90# matrix asphalt into the oven and heat until softened;

[0028] 3) Heat th...

Embodiment 2

[0034] Compared with Example 1, a kind of used tire rubber powder modified asphalt provided in this example, raw materials include by weight: 100 parts of SK-90# base asphalt produced in Korea; 24 parts of 30 mesh waste tire rubber powder 4.5 parts of polyoctene rubber Vita linking agent. Other steps and process parameter are the same as embodiment 1.

Embodiment 3

[0036] A kind of used tire rubber powder modified asphalt provided in this embodiment, the raw material includes by weight: 100 parts of SK-90# base asphalt produced in Korea; 24 parts of 40 mesh waste tire rubber powder; polyoctene rubber vita Linking agent 4.5 parts. Among them, the waste tire rubber powder is the waste radial tire ground and pulverized by the normal temperature process, with a relative density of 1.17, a metal content of 0.02%, a fiber content of 0.07%, an ash content of 6%, and a carbon black content of 33%. Other steps and process parameter are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com