Device and method for continuously preparing charcoal

A biochar and equipment technology, applied in the field of comprehensive utilization of agricultural and forestry waste resources, can solve the problems of insufficient exhaust gas recycling, high carbonization energy consumption, carbonization, etc., and achieves controllable pyrolysis time, high thermal energy utilization rate, and reduced carbonization energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below through specific implementation examples in conjunction with the accompanying drawings.

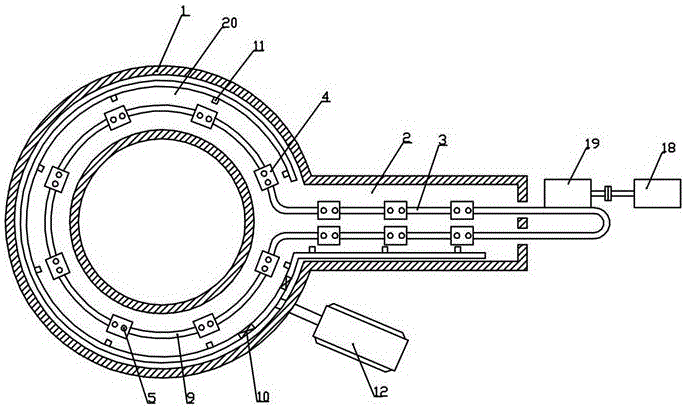

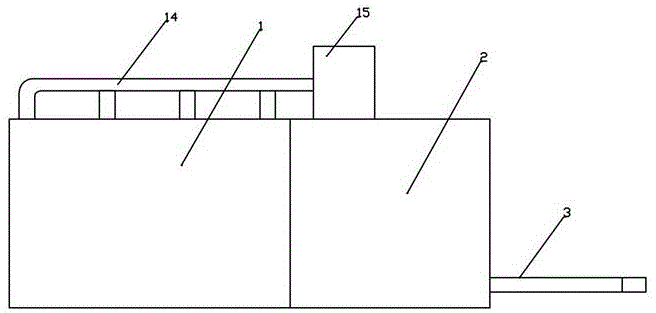

[0035] figure 1 Shows a method for continuous preparation of biochar provided by the present invention, including the following steps:

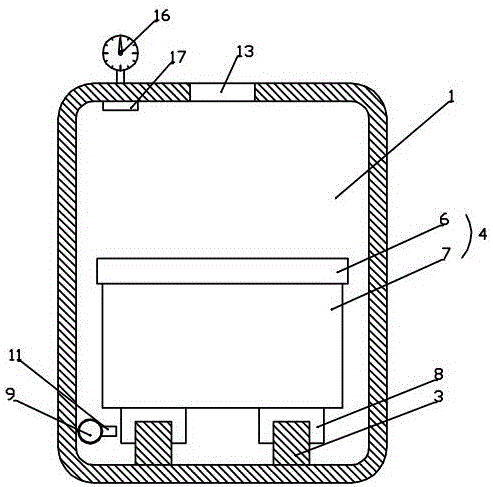

[0036] S1. Inject air into the annular furnace body, and through the operation of the blower, the air outside the annular furnace body will evenly enter the annular furnace body and the material enters and exits the room, ensuring that the annular furnace body and the air entering and exiting the room circulate and are heated by the inside Start to preheat the annular furnace body in a way;

[0037] S2. After drying and crushing agricultural and forestry wastes such as crop stalks, bamboo and wood processing wastes, branches, leaves, fruit husks, peels, distiller’s grains, bagasse, rice hulls, cottonseed husks and waste edible fungi culture medium, they are packed separately Into multiple m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com