Method for preparing coal-based light liquid paraffin from coal indirect liquefied oil product and coal-based light liquid paraffin obtained through method

A light liquid paraffin and oil technology, applied in the field of coal chemical industry, can solve the problems of products without post-processing, poor product quality and economic rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

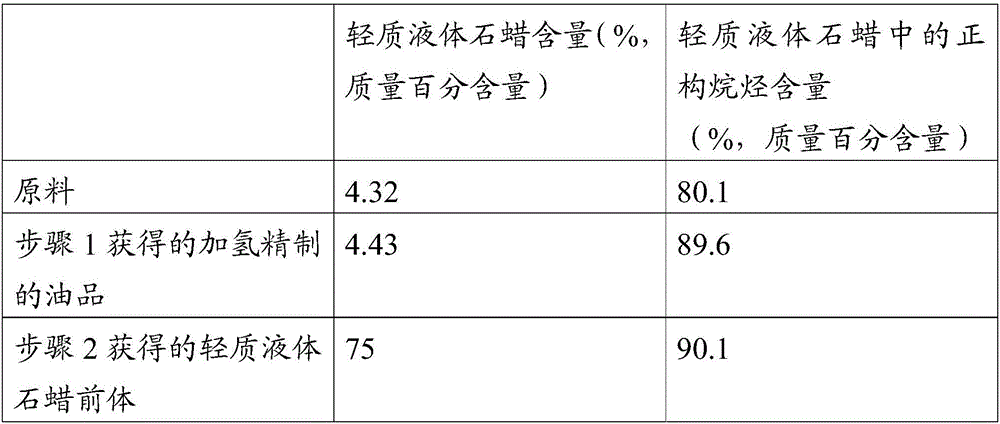

[0042] Example 1. Preparation of coal-based light liquid paraffin by indirect liquefaction of coal

[0043] This method takes coal indirect liquefied oil (i.e. Fischer-Tropsch synthetic oil) as raw material, and mainly carries out three steps of hydrofining, fractionation and dewaxing to prepare coal-based light liquid paraffin, specifically as follows:

[0044] 1. Hydrogenation process flow: Fill the catalyst inside the fixed bed reactor. In order to better control the reaction heat release, the hydrogenation catalyst with a total mass of 58t is 1:1.2:1.7 from top to bottom according to the volume ratio. Filled in three layers with a volume of 212m 3In a fixed-bed reactor with an inner diameter of 4.4m; Fischer-Tropsch synthetic oil and fresh hydrogen are heated to 270-325°C and then enter from the top of the fixed-bed reactor; hydrogen, oil materials and catalysts are fully Mixing for hydrogenation reaction, the volume ratio of hydrogen to oil is 500, the reaction temperatu...

Embodiment 2

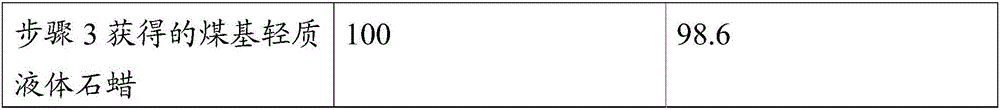

[0053] Example 2, coal-based light liquid paraffin prepared by indirect liquefaction of coal

[0054] The raw material is the same as that used in Example 1, mainly carrying out three steps of hydrofining, fractionation and dewaxing to prepare coal-based light liquid paraffin, specifically as follows:

[0055] 1. Hydrogenation process flow: the filling of the fixed bed reactor and catalyst is the same as in Example 1; after heating the Fischer-Tropsch synthetic oil and fresh hydrogen to 350-380°C, enter from the top of the fixed bed reactor; Oil materials and catalysts are fully mixed inside the fixed bed for hydrogenation reaction, the volume ratio of hydrogen to oil is 300, the reaction temperature is controlled at 260-270°C, the reaction pressure is 6MPa, and the volume space velocity is 1.0-2.4h -1 ; The reactants after catalytic hydrogenation are separated by an oil-gas separator to obtain the oil product part, which is the hydrotreated oil product, and the hydrotreated r...

Embodiment 3

[0063] Example 3, coal-based light liquid paraffin prepared by indirect liquefaction of coal

[0064] The raw material is the same as that used in Example 1, mainly carrying out three steps of hydrofining, fractionation and dewaxing to prepare coal-based light liquid paraffin, specifically as follows:

[0065] 1. Hydrogenation process flow: the loading of the fixed bed reactor and catalyst is the same as in Example 1; after heating the Fischer-Tropsch synthetic oil and fresh hydrogen to 270-325°C, enter from the top of the fixed bed reactor; Oil materials and catalysts are fully mixed inside the fixed bed for hydrogenation reaction, the volume ratio of hydrogen to oil is 700, the reaction temperature is controlled at 380-420°C, the reaction pressure is 9MPa, and the volume space velocity is 1.0-2.4h -1 ; The reactants after catalytic hydrogenation are separated by an oil-gas separator to obtain the oil product part, which is the hydrotreated oil product, and the hydrotreated r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com