Guide mode processing method for flaky sapphire

A processing method, sapphire technology, applied in chemical instruments and methods, self-melting liquid pulling method, single crystal growth, etc., can solve problems such as poor quality of flaky crystals, reduce the probability of bubble generation, improve crystal quality, The effect of reducing the existence of raw material voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

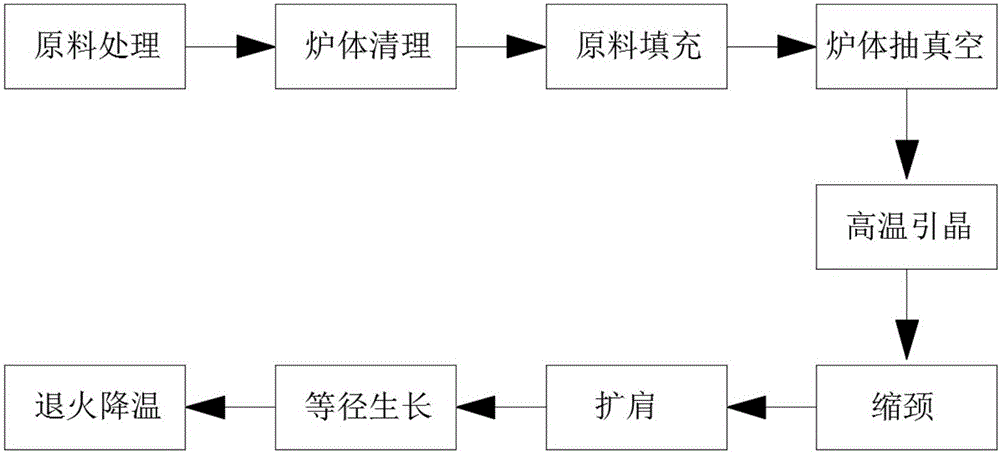

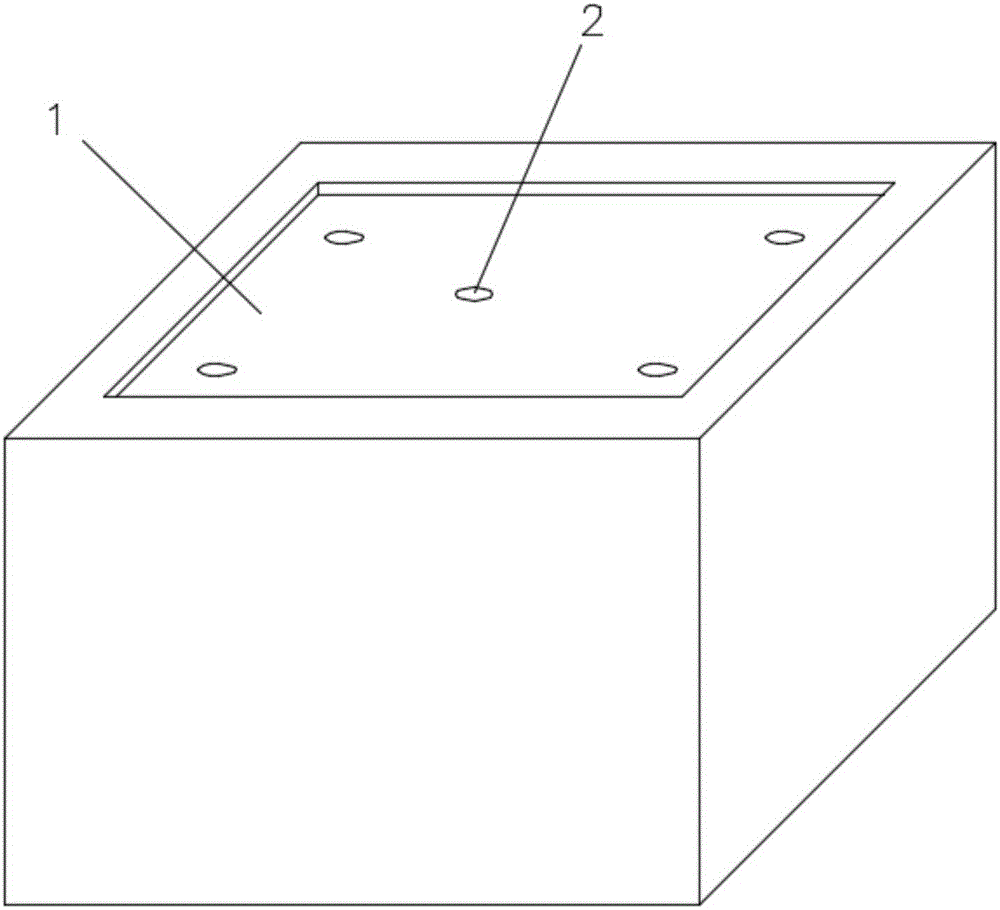

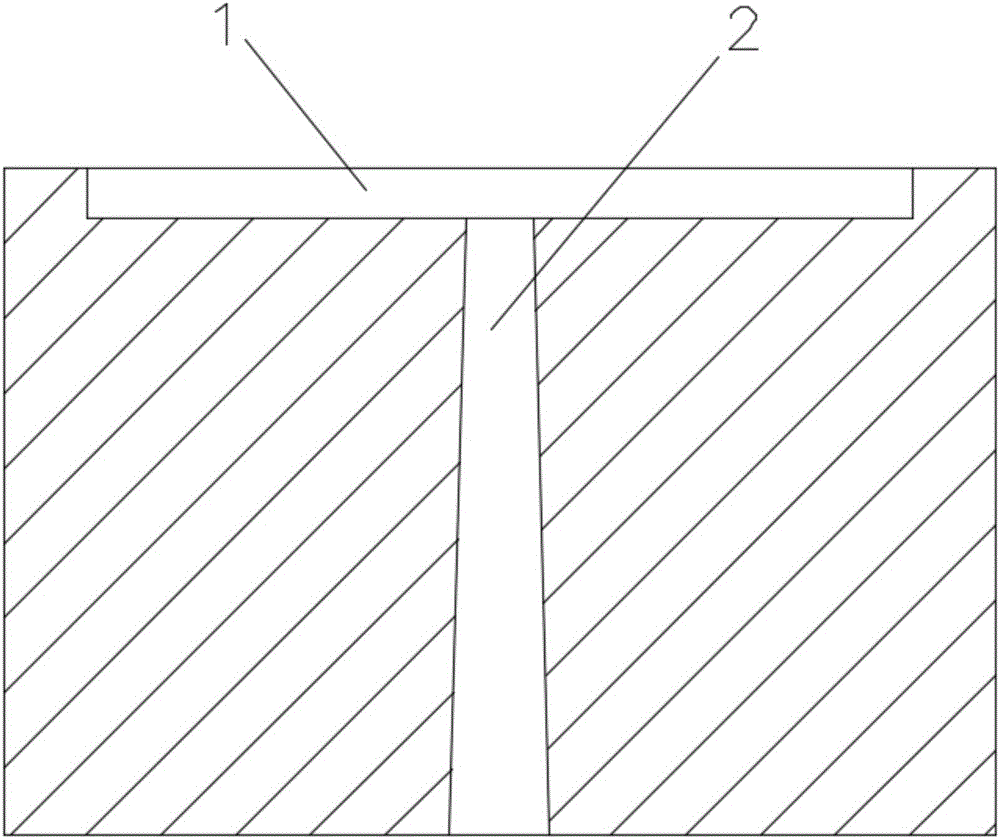

[0034] Example 1, such as Figure 1-3 Shown:

[0035] A kind of guided mode processing method of sheet-shaped sapphire, comprises the steps:

[0036] (1) Raw material processing: The raw material is first ultrasonically cleaned with acetone for 20 minutes, then ultrasonically cleaned with absolute ethanol for 10 minutes, and then ultrasonically cleaned with deionized water for 10 minutes to clean the raw material; Dry in an oven at 120°C for 1h to 1.5h, then soak the raw materials in concentrated hydrochloric acid with a mass fraction of 36%-38% for 26h to 30h, place them in a clean water pool to rinse until neutral, and then put them into a quartz crucible Dry for 1h~2h;

[0037] (2) Cleaning of the furnace body: before processing the flake sapphire with the guide mold, the furnace body shall be strictly inspected first to know whether there are foreign objects or sundries inside the furnace body by means of inspection, and the sundries inside the furnace body shall be clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com